Description

The

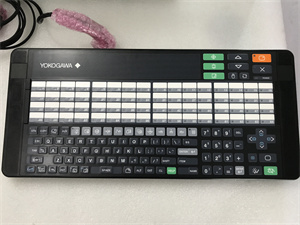

UR1800 is a compact remote I/O unit with a modular design, enabling scalable deployment in distributed control architectures. It operates on a 24 V DC power supply and features dual redundant communication interfaces (e.g., Profibus DP V1) for reliable data transmission. With a lightweight construction (0.5 kg) and IP65/IP66 protection, the unit withstands dust, moisture, and extreme temperatures (-40°C to 70°C). Key functions include digital/analog I/O processing, protocol conversion, and real-time diagnostics. The

UR1800 integrates with Yokogawa’s fieldbus modules (e.g., ADM14, ADM54) for analog/digital signal conditioning, ensuring compatibility with sensors, actuators, and legacy systems.

| Parameter |

Specification |

| Product Type |

Remote I/O Unit (Modular, Rack-Mount/Panel-Mount) |

| Power Supply |

24 V DC (-15% to +20%), redundant option available |

| Communication |

Profibus DP V1 (12 Mbps), Modbus RTU (RS-485), Ethernet/IP (optional) |

| I/O Capacity |

Up to 16 modules per unit (e.g., 16x digital input/output, 8x analog input/output) |

| Compatibility |

Yokogawa Centum VP, ProSafe-RS; third-party devices via standard protocols |

| Environmental Ratings |

IP65/IP66 (front panel), -40°C to 70°C (operation), 5–95% RH (non-condensing) |

| Dimensions |

120 mm (W) x 150 mm (H) x 100 mm (D) |

| Weight |

0.5 kg (unit only); 1.2 kg (with modules) |

| MTBF |

>500,000 hours (at 40°C, according to Yokogawa reliability tests) |

UR1800

- Modular Scalability: Supports up to 16 I/O modules (e.g., ADM14 analog input, DXM14 digital output) for customized configurations.

- Rugged Design: IP65/IP66 protection and wide temperature range (-40°C to 70°C) for outdoor/harsh environments.

- Redundant Architecture: Optional dual power supply and communication links (e.g., Profibus DP redundancy) for zero downtime.

- Real-Time Diagnostics: Built-in LED indicators and remote monitoring via Yokogawa’s ProSafe-RS software for predictive maintenance.

- Energy Efficiency: Low power consumption (≤5 W idle, ≤15 W 满载) with sleep mode for standby operations.

- Industries: Manufacturing (assembly lines), energy (wind/solar farms), water treatment, and oil & gas (pipeline monitoring).

- Scenarios: Remote data acquisition, distributed control in hazardous zones, and machine-to-machine (M2M) communication.

- Case Study: A solar farm in Australia deployed 50 UR1800 units with ADM14 analog modules to monitor 1,000+ solar panels. The units’ IP66 protection and -40°C to 70°C tolerance ensured 99.8% uptime over 2 years, reducing maintenance costs by 30%.

Compared to similar remote I/O units, the UR1800 offers superior environmental ratings (IP66 vs. typical IP65) and native support for Yokogawa’s DCS ecosystems, minimizing integration complexity. Its modular density (16 modules/unit) exceeds most competitors (8–12 modules/unit), while redundant communication (Profibus DP V1 redundancy) is standard—features often optional in 竞品.

YOKOGAWA UR1800

- Protocol Needs: Choose Profibus DP, Modbus RTU, or Ethernet/IP variants based on existing infrastructure.

- Environment: Opt for IP66 models for outdoor use; verify temperature range (-40°C to 70°C) for extreme climates.

- I/O Density: Plan module count (e.g., 8x analog + 8x digital) and chassis size (120 mm width) for space-constrained sites.

- Redundancy: Enable dual power supply and communication links for critical applications (e.g., oil refineries).

- Installation: Ensure proper grounding and cable shielding (e.g., Profibus shielded twisted pair).

- Module Compatibility: Use only Yokogawa-approved I/O modules (e.g., DXM14, ADM54) to maintain warranty and performance.

- Temperature Management: Avoid stacking units in enclosed spaces; ensure adequate ventilation for 70°C operation.

- Redundancy Testing: Regularly validate communication failover (e.g., Profibus DP redundancy) and power supply switching.

声明Shanxi Xinye Da International Trade Co., Ltd. is your trusted partner for

YOKOGAWA UR1800 and automation solutions. We provide genuine spares, technical support, and customized I/O configurations. Visit

www.xydcontrol.com or contact us for expert advice on distributed control systems.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide