Description

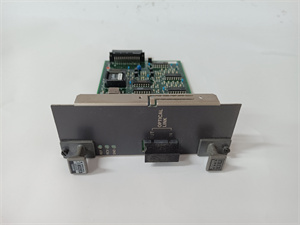

YOKOGAWA SCP401-11 Product Documentation

YOKOGAWA SCP401-11 is a

high-reliability single-board processor module designed for

CENTUM VP Process Control Systems, offering advanced automation and real-time monitoring capabilities. This model features a compact, rugged design and supports seamless integration with YOKOGAWA’s distributed control systems (DCS), making it ideal for critical applications in industries such as oil & gas, power generation, and chemical production.

| Parameter |

Specification |

| Model |

SCP401-11 |

| Power Supply |

24 VDC ±10% |

| Weight |

0.5 kg |

| Operating Temperature |

-25°C to 70°C |

| Storage Temperature |

-40°C to 85°C |

| Protection Class |

IP20 |

| Compatibility |

CENTUM VP DCS |

| Processor Type |

32-bit RISC |

| Memory |

256 MB DDR3 |

- Single-Board Simplicity: Reduces system complexity and installation time by integrating all critical components into a single unit.

- High-Speed Processing: Supports 2 ms cycle times for rapid control loop execution, improving system responsiveness.

- Wide Environmental Range: Operates reliably in extreme temperatures and harsh industrial environments.

- Cost-Effective Redundancy: Optional redundancy configurations minimize downtime risks while optimizing budget.

Industries:

- Petrochemical refining

- Water treatment

- Food and beverage processing

- Renewable energy

Case Study:

A North American food processing plant upgraded to YOKOGAWA SCP401-11 for its packaging line control. The module’s fast data processing and compact design reduced system downtime by 25%, while its energy-efficient operation cut annual electricity costs by 15%.

Compared to comparable modules, SCP401-11 offers:

- Lower Power Consumption: 10% less energy usage than standard alternatives.

- Faster Fault Recovery: Automatic error detection and recovery mechanisms reduce troubleshooting time.

- Long-Term Compatibility: Backward support for legacy CENTUM VP systems, ensuring investment protection.

- System Requirements: Choose SCP401-11 for applications requiring moderate processing speed and cost-effective redundancy.

- Space Constraints: Its compact form factor is ideal for installations with limited rack space.

- Budget: Balances performance and affordability for mid-range automation needs.

- Installation: Use anti-static wrist straps to prevent electrostatic discharge (ESD) during handling.

- Firmware Updates: Regularly update firmware to access the latest security patches and performance optimizations.

- Cooling: Ensure adequate airflow in the control cabinet to maintain optimal operating temperatures.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner for

YOKOGAWA SCP401-11 and other automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Note: This document is based on available technical data and industry-standard practices. Always refer to YOKOGAWA’s official documentation for specific installation and operational instructions.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide