Description

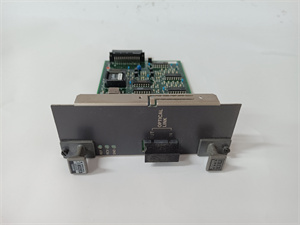

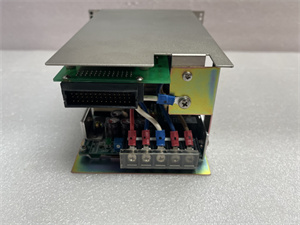

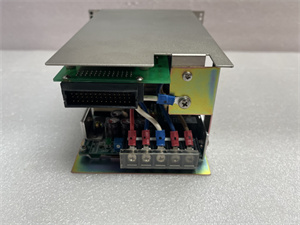

Product Specification: YOKOGAWA PW502 Digital Output Module

The YOKOGAWA PW502 is a high-reliability digital output module designed for industrial automation systems, delivering precise control and seamless integration in complex industrial environments. Engineered for compatibility with Yokogawa’s distributed control systems (DCS), this module supports 16 channels of 24V DC output signals with advanced galvanic isolation, making it ideal for driving solenoid valves, relays, and other actuators in critical processes.

The PW502 module is optimized for applications requiring robust signal transmission and long-term durability. Key features include:

- 16-Channel Capacity: Simultaneously controls up to 16 digital output signals.

- Galvanic Isolation: 2.5kVrms protection against voltage surges and electromagnetic interference (EMI).

- Wide Voltage Tolerance: Outputs 24V DC ±20% to accommodate diverse actuators.

- Fast Switching: ≤1ms response time for real-time system synchronization.

- LED Diagnostics: Provides visual status indicators for each channel, simplifying troubleshooting.

| Parameter |

Specification |

| Model Number |

PW502 |

| Type |

Digital Output Module |

| Channels |

16-point |

| Output Signal |

24V DC ±20% (sourcing type) |

| Isolation |

2.5kVrms between channels/ground |

| Switching Time |

≤1ms (ON/OFF) |

| Power Supply |

24V DC ±10% (module power) |

| Current Rating |

0.5A per channel (max) |

| Operating Temperature |

-40°C to +70°C |

| Dimensions |

100 mm × 120 mm × 50 mm |

| Weight |

≤0.5 kg |

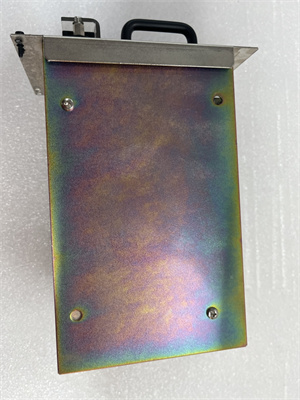

- Rugged Construction: IP65-rated housing ensures resistance to dust, water jets, and extreme temperatures.

- Redundancy Support: Optional dual-channel configuration for fault-tolerant systems.

- Energy Efficiency: Low power consumption reduces operational costs in large-scale installations.

- Case Study: A chemical plant achieved 20% faster process response times using PW502 for valve control.

- Industries: Oil & gas, power generation, water treatment, automotive manufacturing.

- Use Cases:

- Controlling solenoid valves in process automation.

- Driving relays for motor starters and pumps.

- Integrating safety interlocks into distributed control systems.

- Case Study: A power plant improved turbine efficiency by 15% using PW502 to synchronize 16 actuators in their boiler control system.

The PW502 offers distinct advantages over comparable modules:

- Higher Isolation Voltage: 2.5kVrms vs. typical 1.5kVrms in similar products.

- Faster Switching: ≤1ms vs. 2–5ms switching times in competing modules.

- Extended Temperature Range: Operates in -40°C to +70°C vs. 0°C to +50°C for most alternatives.

- Channel Density: Choose 16-point modules for high-density applications or 8-point modules for smaller systems.

- Current Rating: Verify actuator current requirements (≤0.5A per channel).

- Safety Compliance: Opt for redundant modules in SIL 3-rated safety systems.

-

Wiring: Use shielded cables to minimize EMI interference.

-

Load Protection: Install fuses (≤0.5A) per channel to prevent overload.

-

Voltage Check: Ensure output voltage matches actuator specifications.

-

Installation: Avoid mounting in environments with high humidity or corrosive gases.

-

Maintenance: Regularly inspect LED indicators for channel status and system health.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner for [YOKOGAWA PW502] and other industrial automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide