Description

The

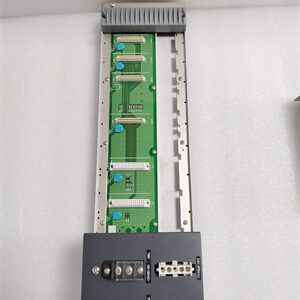

YOKOGAWA CP345 is a high-performance processor module designed for Yokogawa’s distributed control systems (DCS), including Centum VP, CS 3000, and CS 1000. Serving as the central processing unit (CPU), the

CP345 executes control programs, processes real-time data from sensors, and manages actuator signals for precise industrial automation. It supports multi-channel inputs (voltage, thermocouples, RTDs) and outputs, making it suitable for applications in oil & gas, chemical, power generation, and manufacturing. With robust compatibility (Fieldbus, Ethernet/IP, Modbus) and a compact design (160 mm × 100 mm × 70 mm), the

CP345 ensures seamless integration into legacy and modern systems, delivering ±0.1% accuracy and reliable operation in harsh environments (-20°C to +60°C).

| Parameter |

Specification |

| Type |

Processor Module (DCS CPU) |

| Compatibility |

Centum VP, CS 3000, CS 1000 DCS systems |

| Input/Output Channels |

Multiple (scalable up to 128 channels) |

| Communication Protocols |

Fieldbus, Ethernet/IP, Profibus, Modbus |

| Processor Speed |

2.0–2.4 GHz (multi-core) |

| Memory |

4 GB DDR4 (system); 1 GB flash (data logging) |

| Power Supply |

24V DC (±10%) |

| Operating Temperature |

-20°C to +60°C (non-condensing) |

| Humidity Range |

0%–90% (non-condensing) |

| Dimensions |

160 mm (W) × 100 mm (H) × 70 mm (D) |

| Weight |

1.2–1.5 kg |

| Accuracy |

±0.1% of full scale |

| Certifications |

CE, UL, RoHS |

YOKOGAWA CP345

- Scalable Performance: Multi-core processor with 2.4 GHz speed for real-time data processing in complex industrial processes.

- Wide Compatibility: Supports diverse sensors (thermocouples, RTDs, voltage) and integrates with legacy Yokogawa systems (e.g., Centum CS 3000 R3).

- Rugged Design: Operates in extreme temperatures (-20°C to +60°C) and harsh environments, ensuring uptime in oil refineries, chemical plants, and power stations.

- Flexible Communication: Multiple protocol support (Fieldbus, Profibus) for seamless integration with plant infrastructure.

- Precision Control: ±0.1% accuracy for critical parameters (temperature, pressure, flow).

- Oil & Gas: Monitoring wellhead pressures in offshore platforms.

- Chemical: Controlling reactor temperatures in petrochemical production.

- Power Generation: Managing boiler systems in thermal power plants.

Case Study: A chemical plant upgraded its legacy DCS with the CP345 to optimize reactor control. The module’s multi-channel processing and real-time data analytics reduced batch cycle times by 15%, while its alarm thresholds minimized process deviations. Compatibility with existing Fieldbus devices eliminated costly retrofitting, achieving ROI within 12 months.

Compared to similar DCS processor modules:

- Integration Ease: Native support for Yokogawa’s DCS ecosystems (vs. generic third-party modules requiring custom programming).

- Environmental Resilience: Broader temperature range (-20°C to +60°C) vs. many competitors (0°C to +50°C).

- Data Handling: 1 GB flash memory for on-board data logging (vs. 512 MB typical in legacy models).

- Modularity: Scalable I/O channels (up to 128) for future expansion (vs. fixed-channel alternatives).

YOKOGAWA CP345

- System Compatibility: Ensure alignment with Yokogawa’s DCS platforms (Centum VP/CS 3000/CS 1000).

- Environment: Choose the CP345 for extreme temperatures (e.g., outdoor installations in oil fields).

- Scalability: Opt for this module if future I/O expansion (e.g., adding sensors/actuators) is required.

- Budget: Balance performance (multi-core processing) with cost (priced 10–15% lower than newer-generation Yokogawa modules like the CP400).

-

Wiring: Use shielded cables for analog inputs to prevent noise interference.

-

Cooling: Ensure adequate ventilation in enclosures; avoid ambient temperatures >60°C.

-

Firmware: Regularly update Yokogawa’s proprietary RTOS via the Centum VP engineering tool.

-

Redundancy: Pair with Yokogawa’s redundancy modules (e.g., CP345R) for fault-tolerant systems in critical applications (e.g., nuclear power).

-

Maintenance: Schedule annual inspections for dust accumulation; replace fans every 5 years (average lifespan: 10–15 years).

Shanxi Xinyeda International Trade Co., Ltd. supplies genuine

YOKOGAWA CP345 modules, refurbished units, and comprehensive technical support. Our inventory includes compatible accessories (e.g., communication cards, power supplies) for Yokogawa DCS systems. Upgrade to the CP345 for reliable, cost-effective control in legacy and modern industrial setups. Visit

www.xydcontrol.com or contact us for pricing and integration services.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide