Description

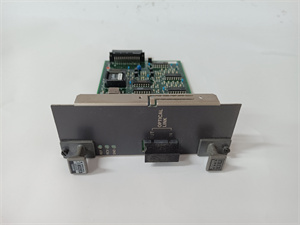

Product Specification: YOKOGAWA AIP591 Analog Input Module

The YOKOGAWA AIP591 is a high-performance analog input module designed for industrial automation systems, delivering precise signal conditioning and data acquisition for process control applications. Optimized for integration with Yokogawa’s CENTUM DCS platforms, the AIP591 ensures reliable operation in harsh environments while supporting advanced features like signal isolation and redundancy.

The

YOKOGAWA AIP591 is engineered to convert analog signals from sensors and transmitters into digital data for DCS systems. Key features include:

- Multi-Signal Support: Accepts voltage (0–10V DC), current (4–20mA), and resistance (RTD) inputs.

- High Precision: ±0.01% accuracy for critical measurements in process industries.

- Channel Isolation: 2.5kV DC isolation per channel to protect against ground loops.

- Redundancy Options: Supports dual-module configurations for fail-safe operation.

- Hot-Swap Capability: Enables module replacement without system shutdown.

| Parameter |

Specification |

| Input Types |

Voltage (0–10V DC), Current (4–20mA), RTD |

| Number of Channels |

8 channels (isolated) |

| Resolution |

16-bit |

| Accuracy |

±0.01% of full scale |

| Sampling Rate |

100 ms/channel |

| Isolation |

2.5kV DC per channel |

| Power Supply |

24V DC ±10% |

| Dimensions |

160×100×50 mm |

| Weight |

0.8 kg |

| MTBF |

300,000 hours |

- Reliability: 300,000-hour MTBF and 2.5kV isolation ensure long-term stability.

- Energy Efficiency: Low power consumption (<5W) reduces operational costs.

- Case Study: A chemical plant improved process accuracy by 0.05% using AIP591 for reactor temperature monitoring.

- Process Industries: Petrochemical, oil, and gas for pressure/temperature monitoring.

- Manufacturing: Automotive and food processing for quality control.

- Energy: Power plants for turbine efficiency optimization.

- Case Study: A power utility achieved 99.9% uptime in boiler control using AIP591’s redundant configuration.

The AIP591 surpasses alternatives with:

- Higher Channel Density: 8 isolated channels vs. 4–6 in comparable modules.

- Faster Sampling: 100 ms/channel for real-time process adjustments.

- Wider Signal Range: Supports RTD inputs for temperature measurements without external modules.

- Input Requirements: Choose AIP591 for mixed voltage/current/RTD applications; use AIP578 for voltage-only needs.

- Redundancy: Opt for dual modules in safety-critical processes.

- Environment: Ensure ambient temperature remains between -20°C to +60°C.

-

Cabling: Use twisted-pair shielded cables to minimize EMI interference.

-

Grounding: Follow Yokogawa’s grounding guidelines for isolated channels.

-

Calibration: Perform annual calibration to maintain accuracy.

-

Firmware Updates: Regularly update CENTUM DCS firmware for compatibility.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner for [YOKOGAWA AIP591] and other industrial automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide