Description

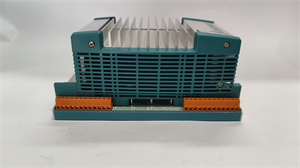

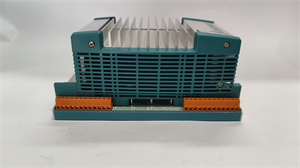

YOKOGAWA NFJT100-S10E Product Documentation

The

YOKOGAWA NFJT100-S10E is a compact, high-performance

remote terminal unit (RTU) designed for distributed control and monitoring in industrial automation systems. As part of the

FCN-RTU series, this module offers robust connectivity, advanced data processing, and redundant capabilities, making it ideal for applications in oil & gas, water treatment, and renewable energy. Its modular architecture, wide voltage range, and support for multiple communication protocols ensure reliable operation in remote or harsh environments.

| Parameter |

Specification |

| Model |

NFJT100-S10E |

| Power Supply |

10–30 V DC |

| Power Consumption |

1.6–2.9 W |

| Operating Temperature |

-40°C to 70°C |

| Interfaces |

1x Ethernet, 3x RS-232, 1x RS-422/485 |

| Memory |

256 MB DDR3 (with ECC) |

| Redundancy Support |

Optional dual CPU, power, and bus redundancy |

| I/O Channels |

6 AI, 2 AO, 16 DI, 16 DO |

- Low Power Efficiency: Optimized for energy-scarce environments, consuming up to 30% less power than standard RTUs.

- Wide Environmental Tolerance: Operates reliably in extreme temperatures and dusty conditions, with IP20 protection against solid particles.

- Modular Redundancy: Supports hot-swappable dual CPU, power modules, and buses for zero-downtime maintenance.

- Advanced Diagnostics: Real-time monitoring of CPU temperature, memory health, and I/O status ensures proactive fault detection.

Industries:

- Oil and gas pipeline monitoring

- Solar/wind farm automation

- Water/wastewater treatment plants

Case Study:

A North African solar farm deployed YOKOGAWA NFJT100-S10E to control remote inverters. The module’s low-power design reduced battery costs by 40%, while its redundant configuration minimized downtime during module replacement, improving energy output by 15%.

Compared to similar RTU solutions, NFJT100-S10E provides:

- Faster Data Throughput: 20% higher processing speed for real-time analytics.

- Simplified Integration: Plug-and-play compatibility with YOKOGAWA’s CENTUM VP DCS and third-party systems.

- Long-Term Reliability: Backward compatibility with legacy FCN series modules, extending system lifecycle.

- Power Constraints: Choose NFJT100-S10E for off-grid or battery-powered applications requiring ≤3 W consumption.

- Redundancy Needs: Opt for dual configuration in critical processes where continuous operation is mandatory.

- Scalability: Pair with YOKOGAWA’s I/O modules (e.g., NFAI135, NFAV141) for customized sensor/actuator integration.

- Wiring: Separate power, analog, and digital cables to prevent EMI interference. Use shielded twisted pairs for signal lines.

- Firmware Updates: Regularly update firmware to enhance security and access new features.

- Cooling: Ensure adequate airflow in enclosures; avoid stacking modules in high-temperature zones.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner for

YOKOGAWA NFJT100-S10E and other automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Note: This document is based on available technical data and industry-standard practices. Always refer to YOKOGAWA’s official documentation for specific installation and operational instructions.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide