Description

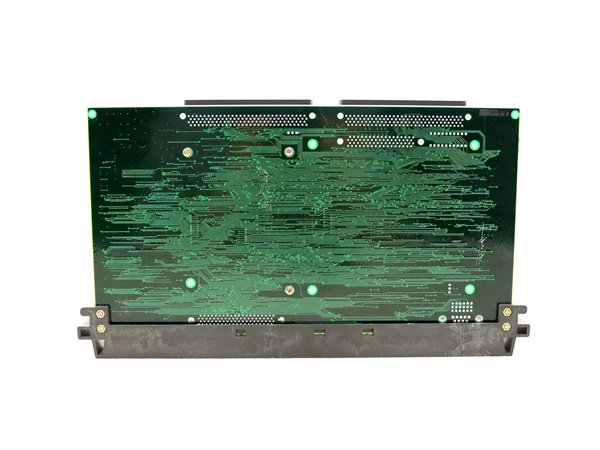

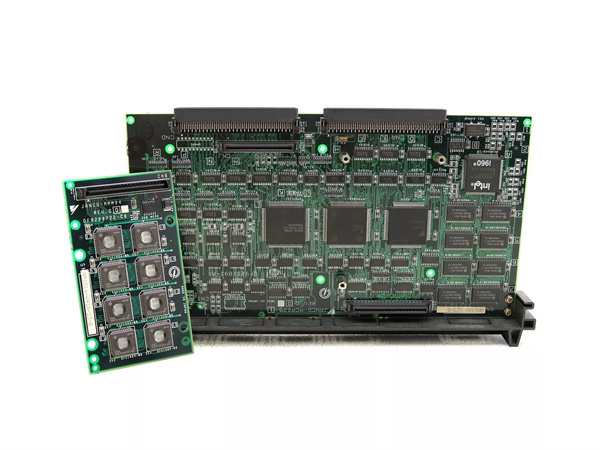

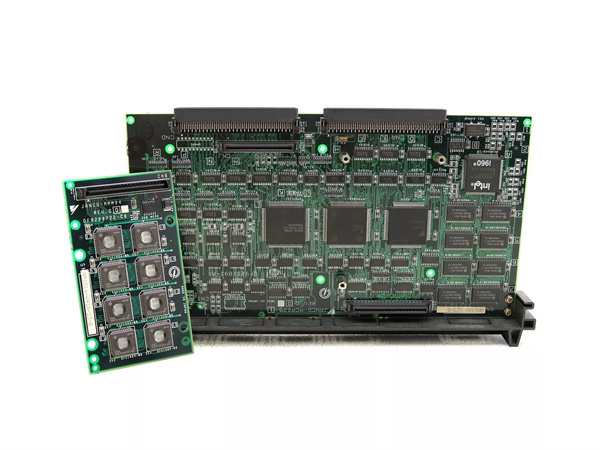

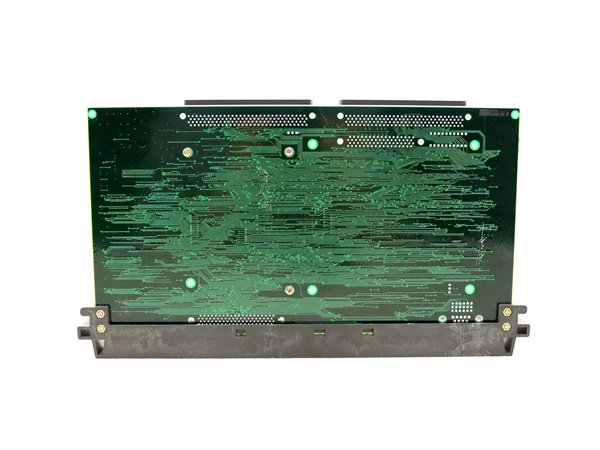

Product Specification: Yaskawa Motoman JANCD-MSV01B Motion Control Board

The

Yaskawa Motoman JANCD-MSV01B is a high-performance motion control board designed for industrial robotics and automation systems. As part of Yaskawa’s advanced MRC (Motion Robot Controller) series, this module supports synchronized multi-axis control, offline programming, and seamless integration with Motoman robots, ensuring precision and efficiency in manufacturing, automotive, and logistics applications.

The JANCD-MSV01B serves as the core of Yaskawa Motoman’s MRC system, enabling real-time coordination of up to 21 axes for complex robotic tasks. Key features include:

- Dual-Robot Synchronization: Coordinates two robots for collaborative operations.

- Offline Programming: Allows program editing via PC for reduced downtime.

- Expandable I/O: Supports up to 144 signals (standard 48) for flexible integration.

- Multi-Tasking Capability: Manages simultaneous processes like machine tending and welding.

- Compact Design: Space-efficient layout for modular system configurations.

| Parameter |

Specification |

| Input Voltage |

24V DC ±10% |

| Control Axes |

Up to 21 axes |

| I/O Signals |

48 standard (expandable to 144) |

| Communication |

Ethernet, RS-232/422 |

| Programming Capacity |

2,200 positions (upgradable to 60,000) |

| Operating Temperature |

0°C to +55°C |

| Weight |

0.33 kg |

| Certifications |

CE, UL, RoHS |

- Scalability: Supports up to 60,000 positions and 144 I/O signals, adapting to evolving production needs.

- Redundancy: Dual-channel architecture ensures uninterrupted operation in critical applications.

- Energy Efficiency: Low power consumption (<50W) reduces operational costs.

- Case Study: A automotive plant improved welding cycle times by 20% using JANCD-MSV01B for synchronized dual-robot arms.

- Automotive: Welding, painting, and assembly lines.

- Logistics: Palletizing, packaging, and material handling.

- General Manufacturing: CNC machine tending and quality inspection.

- Case Study: A logistics hub achieved 99.9% uptime in palletizing operations using JANCD-MSV01B for real-time error correction.

The JANCD-MSV01B outperforms alternatives with:

- Higher Axis Capacity: 21 axes vs. typical 16–18 axes in comparable systems.

- Faster Response Time: <10ms motion synchronization for high-speed tasks.

- Cost-Effective Expansion: Modular I/O scaling without replacing the entire system.

- Axis Requirements: Choose the JANCD-MSV01B for systems needing 12–21 axes; opt for lower-axis models (e.g., JANCD-MSV02) for simpler tasks.

- Environment: Ensure compatibility with factory temperatures (0°C–55°C) and EMI shielding.

- Future-Proofing: Invest in upgradable programming capacity (60,000 positions) for long-term scalability.

-

Electrostatic Discharge (ESD): Use anti-static wrist straps and conductive packaging during handling.

-

Firmware Updates: Regularly update firmware to access new features and security patches.

-

Power Stability: Use a UPS to protect against voltage fluctuations.

-

Installation: Follow Yaskawa’s wiring guidelines to avoid signal interference.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner for [Yaskawa Motoman JANCD-MSV01B] and other industrial automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide