Description

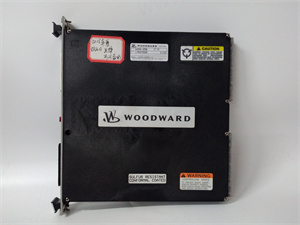

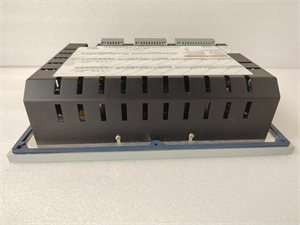

WOODWARD 9907-164 Digital Microprocessor Controller Module

The

WOODWARD 9907-164 is a high-performance digital microprocessor controller module designed for precise control of steam turbines, turbogenerators, and turboexpander systems. Built for industrial automation, it supports single or split-range actuators, enabling accurate speed regulation, load management, and system synchronization. Key features include real-time data processing, configurable I/O interfaces, and advanced protection functions like critical speed avoidance. With a user-friendly 24-character LCD display and intuitive keypad, the 9907-164 allows on-site configuration and monitoring, making it ideal for power generation, oil & gas, and manufacturing applications.

| Parameter |

Specification |

| Input Voltage |

+24 VDC (1 A) |

| Communication |

RS-232/RS-422, Modbus RTU |

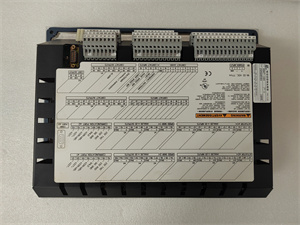

| I/O Interfaces |

16 contact inputs (4 dedicated, 12 programmable), 6 analog inputs (4–20 mA) |

| Display |

2-line x 24-character LCD |

| Operating Temperature |

-20°C to +60°C (-4°F to +140°F) |

| Storage Temperature |

-40°C to +85°C (-40°F to +185°F) |

| Enclosure Rating |

IP56 (front panel mount) |

| Weight |

4.13 kg (9.11 lbs) |

| Certifications |

CE, UL |

- Flexible Control: Supports single or split-range actuators for steam turbine inlet valves, adapting to diverse system requirements.

- Critical Speed Avoidance: Automatically bypasses unsafe speed ranges to prevent mechanical damage.

- Real-Time Monitoring: Tracks parameters like speed, temperature, and pressure with 1 ms resolution.

- Modular Design: Expandable via additional I/O modules for complex control scenarios.

- Fault Tolerance: Built-in diagnostics and first-out shutdown indicators reduce downtime.

- Power Generation: Optimizes steam turbine performance in thermal power plants.

- Oil & Gas: Controls turboexpanders in gas processing facilities.

- Manufacturing: Manages rotating machinery in industrial automation lines.

Case Study:

A European power plant reduced maintenance costs by 30% using the 9907-164 to automate turbine speed control and detect early signs of component wear.

Compared to similar controllers:

- Wider Input Voltage Range: Operates at +24 VDC, reducing reliance on voltage regulators.

- Enhanced I/O Flexibility: Offers 16 contact inputs vs. typical 8–12 in mid-range models.

- Integrated Safety: Combines control and protection functions in a single module, minimizing system complexity.

- System Complexity: Choose the 9907-164 for multi-actuator systems requiring split-range control.

- Environment: Opt for IP56-rated models in harsh conditions (e.g., dusty or humid environments).

- Scalability: Pair with Woodward’s 8440-2028 I/O modules for future expansions.

- Grounding: Ensure proper grounding to prevent EMI interference.

- Firmware Updates: Regularly update via Woodward’s LeoPC software for compatibility and bug fixes.

- Power Supply: Use a filtered power source to avoid voltage spikes.

- Installation: Mount vertically in a vibration-free environment away from high-power cables.

声明山西鑫业达国际贸易有限公司 is your trusted partner for

WOODWARD 9907-164 and turbine control solutions. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide