Description

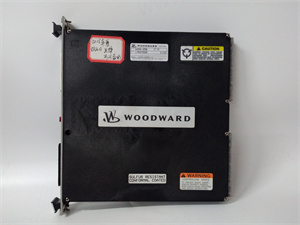

The WOODWARD 9907-164 is a CE/UL-certified digital microprocessor controller module designed for steam turbines, turbogenerators, and turboexpanders. As part of the Woodward 505/505E series, it offers precise control over turbine speed, load, and critical operations like startup and shutdown. The 9907-164 supports single extraction or admission configurations, leveraging split-stage actuators to manage steam inlet valves efficiently. Its rugged design and EMI/RFI shielding ensure reliability in harsh industrial environments.

| Parameter |

Specification |

| Module Type |

Digital Turbine Governor |

| Input Voltage |

+24Vdc ±10% (1A max) |

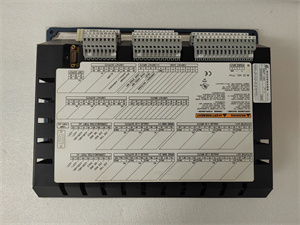

| Discrete Inputs |

16 contact inputs (4 dedicated, 12 programmable) |

| Analog Inputs |

6 × 4–20mA current inputs |

| Outputs |

2 × 4–20mA (actuator control) |

| Communication |

RS-232/RS-422 with Modbus RTU |

| Operating Temperature |

-40°C to +60°C |

| Dimensions |

14W × 11H × 4D inches |

| Weight |

9.11 lbs |

| Display |

2-line × 24-character LCD |

- Precision Control:

- Critical speed avoidance and auto-start sequence optimize turbine performance.

- Valve limiters prevent overloading during operation.

- Flexibility:

- Programmable I/O configuration adapts to diverse turbine setups.

- Supports both isochronous (fixed speed) and droop (variable speed) modes.

- Reliability:

- Self-diagnostic capabilities and first-out shutdown indicators reduce downtime.

- CE/UL certification ensures compliance with global safety standards.

- Energy: Power plants, combined cycle systems.

- Manufacturing: Industrial steam turbines for process control.

- Oil & Gas: Turboexpanders in cryogenic applications.

Case Study: A North American power plant integrated the 9907-164 to manage a steam turbine fleet, achieving 98.5% uptime and a 15% reduction in maintenance costs through predictive diagnostics.

The 9907-164 distinguishes itself with:

- Dual Communication Options: Native Modbus RTU and RS-232/422 compatibility for seamless integration with DCS systems.

- Field Configurability: Front-panel keypad and LCD allow on-site adjustments without external tools.

- Redundancy Support: Expandable I/O for dual-actuator setups, enhancing system resilience.

- Application Type: Choose the 9907-164 for single-extraction turbines; opt for higher models (e.g., 9907-167) for multi-stage configurations.

- Environment: Ensure compatibility with operating temperatures (-40°C to +60°C) and humidity (95% RH for 48 hours).

- Software: Pair with Woodward’s 505 View or OP View™ for advanced monitoring and troubleshooting.

- Installation: Use shielded cables for analog inputs to minimize noise interference.

- Load Management: Avoid exceeding 20mA output to prevent actuator damage.

- Calibration: Schedule annual checks to verify sensor accuracy and software updates.

Shanxi Xinyeda International Trade Co., Ltd. supplies

WOODWARD 9907-164 and automation solutions. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide