Description

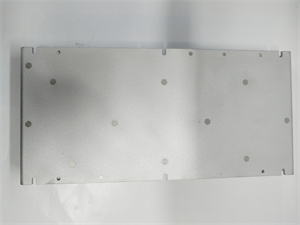

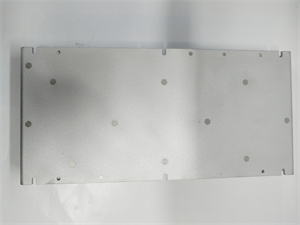

WOODWARD 8273-140 2301D Fuel Control Actuator Documentation

The

WOODWARD 8273-140 2301D is a high-precision fuel control actuator designed for industrial gas turbines, reciprocating engines, and power generation systems. Engineered to deliver reliable and responsive fuel metering, this module ensures optimal combustion efficiency and operational stability in critical applications. Its robust construction and advanced control capabilities make it ideal for harsh environments, including energy, oil & gas, and marine sectors.

| Parameter |

Specification |

| Control Type |

Hydraulic/electric fuel actuation |

| Input Signals |

4-20mA analog command, position feedback |

| Outputs |

Linear/rotary motion control |

| Power Supply |

24V DC ±10% |

| Stroke Range |

0–100% proportional positioning |

| Response Time |

<200ms for full stroke |

| Operating Temperature |

-40°C to +85°C |

| Material |

Stainless steel and aluminum alloy |

- Precision Control:

- ±0.5% positional accuracy under dynamic loads.

- Closed-loop feedback for continuous adjustment.

- Durability:

- IP67-rated housing for waterproof and dustproof performance.

- High-pressure resistance up to 3,000 psi.

- Energy Efficiency:

- Low power consumption (<15W during operation).

- Reduced fuel waste through optimized metering.

- Remote Monitoring:

- Built-in diagnostics for predictive maintenance.

- Compatible with Woodward’s ProAct control software.

- Energy: Gas turbine power plants, combined cycle systems.

- Oil & Gas: Compressor stations, offshore platforms.

- Marine: Engine propulsion systems.

- Industrial: Standby generators, process machinery.

Case Study: A U.S. energy company upgraded to the 8273-140 2301D in their gas turbines, achieving a 12% reduction in fuel consumption and a 30% increase in mean time between failures (MTBF).

The WOODWARD 8273-140 2301D stands out due to:

- Faster Response: <200ms full-stroke time vs. standard 300–500ms.

- Higher Pressure Handling: Supports up to 3,000 psi vs. typical 2,000 psi.

- Integrated Safety: Automatic fail-safe mode and overpressure protection.

- System Compatibility: Verify compatibility with engine fuel system pressure and control signals.

- Environment: Choose IP67-rated models for outdoor or submerged applications.

- Maintenance: Opt for units with replaceable seals for easy field servicing.

- Installation: Ensure proper alignment to prevent mechanical stress.

- Hydraulic Systems: Use clean, filtered oil to avoid actuator damage.

- Calibration: Perform periodic zero-point and span adjustments.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

WOODWARD 8273-140 2301D and automation solutions. Visit

www.xydcontrol.com or contact us for sales and technical support.

Note: Specifications may vary based on configuration. For detailed technical data, refer to the official WOODWARD documentation.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide