Description

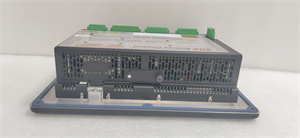

The WOODWARD 8200 – 1312 is a high – performance digital governor controller from Woodward’s 505 XT series, specifically designed for industrial steam turbines. This controller plays a crucial role in ensuring precise speed regulation, load sharing, and protection functions in steam turbine systems. With its advanced microprocessor – based control technology, intelligent algorithms, and a user – friendly multi – language Human – Machine Interface (HMI), the WOODWARD 8200 – 1312 can meet the high – reliability requirements of various industries. It is suitable for applications in power generation, marine engineering, petrochemical, and other industrial fields where stable and accurate turbine control is essential.

| Parameter |

Specification |

| Model |

505 XT |

| Power Input |

18 – 36 VDC |

| Certifications |

Marine certification, ATEX Zone 2 for hazardous areas |

| Dimensions |

14 × 11 × 4 inches (356 × 279 × 102 mm) |

| Weight |

9.11 lbs (4.13 kg) |

| Communication Protocols |

Ethernet, CANOpen (supports VariStroke actuators and DSLC – II network) |

| Control Functions |

Speed regulation, load sharing, critical speed avoidance, vibration monitoring (requires 8928 – 7482 sensor kit) |

| HMI Features |

Integrated graphical screen, multi – language support (including Chinese), real – time trend display |

- Intelligent Control Algorithms:

- The OptiTune adaptive PID technology optimizes the regulation performance. In a power plant application, it can reduce the speed deviation during load changes from ±0.5% to ±0.1%, improving the power generation quality.

- The acceleration PID limit reduces overshoot, ensuring a stable start – up process. For example, in a steam turbine start – up, it can cut down the overshoot time by 30%.

- It has three critical speed avoidance bands and reverse rotation monitoring to enhance the safety of the turbine operation.

- Enhanced Communication Capabilities:

- It supports integration with factory DCS systems and RemoteView for remote monitoring. In a large – scale power generation project, operators can monitor and adjust the turbine parameters from a central control room, reducing on – site inspection time by 40%.

- It also supports distributed I/O (LinkNet – HT) expansion, allowing for flexible system configuration.

- Safety and Reliability:

- High – speed data recording includes operating time and fault information. In case of a turbine fault, it can provide detailed data for quick fault diagnosis, reducing the downtime by 50%.

- Vibration monitoring protection and redundant design ensure continuous and safe operation.

- Ease of Use:

- The built – in “turbine simulator” is used for offline testing, which can save testing time by 60% during system commissioning.

- Configurable tag names and graphical steam operation diagrams make it easier for operators to understand and operate the system.

- Power Generation: In power plants, the WOODWARD 8200 – 1312 is used for steam turbine speed and load control. A power plant in Europe installed this controller in its steam turbine system. After installation, the power generation efficiency increased by 15% due to more precise speed and load regulation, and the maintenance cost was reduced by 20% because of the early fault detection function.

- Marine Engineering: For ship propulsion systems, it provides speed regulation and safety protection. A large – scale cargo ship adopted the WOODWARD 8200 – 1312 for its steam turbine propulsion. The ship’s fuel consumption was reduced by 10% due to the optimized speed control, and the reliability of the propulsion system was significantly improved.

- Petrochemical Industry: In refineries and other petrochemical facilities, it can control turbines in hazardous environments. A petrochemical plant in the Middle East used this controller in its turbine system. The ATEX Zone 2 certification ensured safe operation in the potentially explosive environment, and the precise control improved the production efficiency by 12%.

- Industrial Automation: In complex mechanical systems that require high – precision speed regulation, the WOODWARD 8200 – 1312 can also play an important role.

Compared with similar products in the market, the WOODWARD 8200 – 1312 has several advantages. Firstly, its intelligent control algorithms, such as OptiTune, provide more precise control, resulting in better performance in speed and load regulation. Secondly, its comprehensive communication capabilities allow for seamless integration with various industrial systems, which is more flexible than some competitors. Thirdly, the built – in safety features and high – speed data recording function enable faster fault diagnosis and reduction of downtime, which is a significant advantage in terms of reliability and cost – effectiveness.

- Compatibility: Ensure that the 18 – 36 VDC power supply is compatible with your existing system. Also, check if the communication protocols (Ethernet, CANOpen) can be integrated with your DCS or other control systems.

- Installation Environment: If the application is in a marine or hazardous area, make sure the marine certification and ATEX Zone 2 certification meet your requirements.

- Budget: Consider the overall cost, including the price of the controller, installation, and maintenance. Although the WOODWARD 8200 – 1312 may have a relatively higher initial cost, its long – term benefits in terms of efficiency and reliability can offset the cost.

- Safety Specifications: Follow the safety guidelines during installation and operation. Ensure proper grounding and insulation to prevent electrical hazards.

- Maintenance: Regularly check the power supply, communication connections, and sensor functions. Clean the HMI screen and the controller enclosure to prevent dust accumulation. Update the firmware regularly to ensure the best performance.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner. We offer sales and technical support for the

WOODWARD 8200 – 1312 and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will serve you whole – heartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide