Description

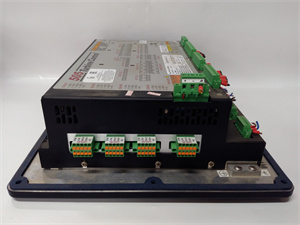

WOODWARD 8200-1302 Digital Turbine Governor Controller

1.Product Description

The WOODWARD 8200-1302 is a high-performance digital governor controller designed for steam turbine applications,offering precise speed regulation,load control,and advanced protection features.As part of Woodward’s 505 series,it integrates a graphical HMI interface with intelligent control algorithms to optimize turbine efficiency and reliability.Key functions include adaptive PID tuning,critical speed avoidance,and real-time diagnostics.The controller supports single or dual split-stage actuators,making it suitable for power generation,oil&gas,and marine environments.

2.Product Parameters

Parameter Specification

Input Voltage 18–36 VDC(low-voltage,isolated)

Analog Inputs 8×4–20 mA(loop-powered)

Communication Modbus RTU/Modbus TCP,Ethernet,CANopen

Control Modes Speed,load,synchronization

Enclosure Rating IP54(marine/ATEX Zone 2 compliant)

Operating Temperature-22°C to+70°C(-7°F to+158°F)

Display 8.4-inch color LCD with multilingual support

3.Advantages and Features

Precision Control:

±0.1%speed accuracy and advanced load rejection capabilities.

OptiTune adaptive PID technology minimizes overshoot by 30%.

User-Friendly Interface:

Large LCD screen with configurable tags and real-time trending.

Built-in“turbine simulator”for offline training and testing.

Reliability:

Industrial-grade design with EMI shielding and vibration resistance.

Redundant speed inputs and self-diagnostics for fault detection.

Flexibility:

Supports up to 3 critical speed bands and reverse rotation sensing.

Easy retrofit for legacy 505 systems using wiring kit 5404-1801.

4.Application Areas and Case Studies

Power Generation:Steam turbine control in thermal power plants.

Oil&Gas:Compressor train regulation in refineries.

Marine:Diesel-electric propulsion systems.

Case Study:

A European power plant upgraded to the 8200-1302 and achieved a 12%reduction in fuel consumption while enhancing load stability.

5.Competitive Comparison

The 8200-1302 stands out with:

Dual Compliance:Marine/ATEX certification for hazardous environments.

Integrated HMI:Built-in graphical interface eliminates need for external displays.

Future-Proofing:Ethernet connectivity and remote monitoring via Woodward’s RemoteView tool.

6.Selection Recommendations

Voltage Compatibility:Choose between LV(18–36 VDC)or AC/DC models(e.g.,8200-1312 for broader voltage ranges).

Environment:Ensure IP54 rating matches installation conditions(e.g.,marine vs.industrial).

Upgrade Path:Use retrofit kits for seamless replacement of older 505 models like 9907-164.

7.Precautions

Installation:Use shielded cables for signal inputs to prevent interference.

Calibration:Verify sensor accuracy annually using Woodward’s Control Assistant tool.

Software Updates:Regularly update firmware to access new features and security patches.

声明

山西鑫业达国际贸易有限公司is your trusted partner for WOODWARD 8200-1302 and automation solutions.Visit www.xydcontrol.com or contact us for sales and technical support.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide