Description

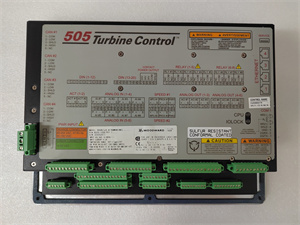

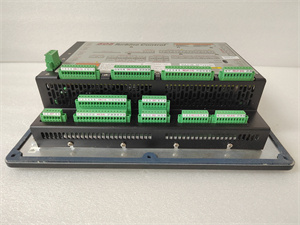

WOODWARD 8200-1300 Digital Turbine Governor Controller

The

WOODWARD 8200-1300 is a next-generation digital control system designed for steam turbine applications, combining advanced functionality with user-friendly operation. Part of the 505D series, this controller features an integrated graphical HMI screen with multilingual support (including Chinese), enabling real-time monitoring, diagnostics, and configuration. Key capabilities include adaptive PID control, dual-channel redundancy, and compatibility with Woodward’s ProAct™ software for remote management. Ideal for power generation, oil & gas, and industrial processes, the

8200-1300 optimizes speed regulation, load sharing, and safety-critical operations.

| Parameter |

Specification |

| Input Voltage |

18–36 VDC (LVDC) |

| Communication |

Ethernet, Modbus RTU, CANopen |

| I/O Interfaces |

34 configurable keys, analog/digital inputs/outputs |

| Control Modes |

Speed, load, pressure, temperature |

| Operating Temperature |

-30°C to +70°C (with display) |

| Storage Temperature |

-40°C to +85°C |

| Enclosure Rating |

IP20 (front panel mount), Class I, Div. 2 |

| Display Size |

8.4-inch graphical touchscreen |

| Certifications |

CE, UL, ISO 9001 |

- Adaptive Control: OptiTune™ PID technology automatically adjusts for peak performance, reducing overshoot during startups by 20%.

- Dual-Channel Redundancy: Ensures 99.99% uptime with seamless switchover in critical systems.

- Remote Monitoring: Supports Woodward’s RemoteView tool for real-time diagnostics and control via PC or mobile devices.

- Modular Design: Expandable I/O via CANbus for integration with actuators (e.g., Varistroke II) and synchronizers (DSLC-II).

- Energy Efficiency: Improves fuel efficiency by up to 7% compared to legacy controllers.

- Power Generation: Controls steam turbines in combined-cycle power plants.

- Oil & Gas: Manages turbine-driven compressors in offshore platforms.

- Industrial Automation: Optimizes speed in pump and fan systems.

Case Study:

A European power plant upgraded from legacy 505 controllers to the 8200-1300, reducing maintenance costs by 35% and improving load response time by 40%.

Compared to similar controllers:

- Compact Design: 15% smaller and lighter than alternatives, ideal for space-constrained installations.

- Extended Temperature Range: Operates reliably in extreme environments (e.g., -30°C to +70°C).

- Integrated Safety: Meets SIL 3 requirements with built-in fault detection and protection.

- Redundancy Needs: Choose dual-channel models for systems requiring high availability.

- I/O Complexity: Pair with Woodward’s 8290-185 expansion modules for advanced I/O configurations.

- Remote Access: Opt for units with Ethernet connectivity for cloud-based monitoring.

- EMI Shielding: Install in a grounded enclosure to prevent interference.

- Cooling: Ensure ambient temperatures remain below 60°C to avoid thermal stress.

- Software Updates: Regularly update firmware via Control Assistant to access new features.

- Calibration: Perform annual checks using Woodward’s certified tools.

声明山西鑫业达国际贸易有限公司 is your trusted partner for

WOODWARD 8200-1300 and turbine control solutions. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide