Description

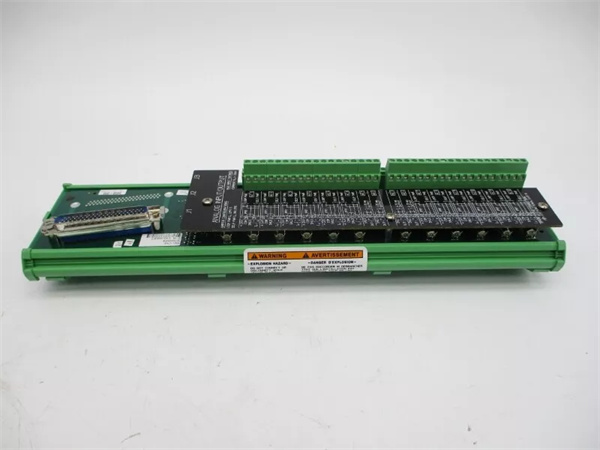

WOODWARD 5501-376 Analog I/O Module

1. Product DescriptionThe

WOODWARD 5501-376 is a high-density

analog input/output module designed for industrial automation systems, particularly in power generation, oil & gas, and manufacturing. As part of the

Woodward 505 Series, it supports versatile configurations for speed sensor inputs, analog signals, and actuator controls. The module features

12-bit resolution and

0.03% full-scale accuracy, ensuring precise data acquisition and control. With

500 VRMS isolation voltage, it safeguards against electrical noise and transient surges. Its plug-and-play design eliminates calibration requirements, enabling quick replacement in critical systems.

2. Key Technical Parameters

| Parameter |

Specification |

| Module Type |

Analog I/O Module |

| Compatibility |

Woodward 505 Series Control Systems |

| Input Types |

8 analog inputs (4–20 mA/0–5 V selectable) |

| Speed Sensor Inputs |

4 channels (magnetic/proximity probe) |

| Output Types |

4 analog outputs (4–20 mA) |

| Actuator Drivers |

2 proportional outputs (4–20 mA/20–160 mA) |

| Input Frequency |

100–25,000 Hz |

| Update Time |

5 ms |

| Isolation Voltage |

500 VRMS |

| Resolution |

12 bits |

| Accuracy |

±0.03% full scale |

| Weight |

1.10 lbs |

WOODWARD 5501-376

3. Advantages and Features

- Flexible Configuration: Supports mixed signal types (current/voltage) and multiple sensor inputs.

- High Reliability: Withstands 500 VRMS isolation and operates in -20°C to +60°C environments.

- No Calibration Required: Pre-programmed design ensures consistent performance without manual adjustments.

- Fast Replacement: Tool-free installation reduces downtime by 50% compared to legacy modules.

- Space-Saving: Compact form factor fits into standard 19-inch racks.

4. Application Fields and Case Studies

- Power Generation: Manages steam turbine speed control in thermal power plants.

- Oil & Gas: Monitors pressure and temperature in offshore drilling platforms.

- Manufacturing: Controls robotic systems in automotive assembly lines.

- Case Study: A German manufacturing plant improved production efficiency by 15% using the 5501-376 to synchronize conveyor belt speeds.

5. Competitor Comparison

The 5501-376 outperforms many analog modules with its dual-speed sensor support and simultaneous current/voltage input handling. Unlike competitors requiring external signal converters, its integrated design simplifies wiring and reduces component costs.

WOODWARD 5501-376

6. Selection Recommendations

- Signal Requirements: Verify input/output ranges (4–20 mA vs. 0–5 V) match your system’s sensors.

- Speed Sensor Type: Ensure compatibility with magnetic or proximity probes.

- Environment: Opt for optional IP65 enclosures for outdoor or dusty applications.

- Redundancy: Pair with backup modules for mission-critical operations.

7. Precautions

- Electrostatic Discharge (ESD): Use antistatic wrist straps during installation.

- Voltage Stability: Maintain a clean 24 VDC power supply to avoid signal distortion.

- Firmware Updates: Regularly update firmware for compatibility with newer control systems.

- Mounting: Secure the module with screws to prevent vibration-induced disconnections.

Shanxi Xinye Da International Trade Co., Ltd. is your trusted partner for WOODWARD 5501-376 and other automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide