Description

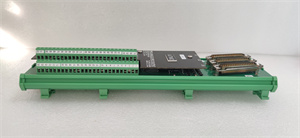

Product Specification:WOODWARD 5441-693

1.Product Description

The WOODWARD 5441-693 is a digital microprocessor-based controller designed for steam turbine applications,specifically integrating with the WOODWARD 505 control system.It serves as a critical component for regulating turbine speed,load,and steam valve actuation,ensuring precise and reliable operation.This module supports both single and dual actuator configurations,making it adaptable to diverse industrial setups.Its modular design and intuitive programming interface enable seamless integration into power generation,oil&gas,and process control systems.

2.Product Parameters

Parameter Specification

Input Voltage 12–24 VDC or 100–250 VAC(selectable)

Output Signals Analog(4–20 mA,0–10 V)and digital(24 VDC)

Communication RS-485(Modbus RTU),Ethernet(Modbus TCP)

Control Modes Speed control,load sharing,start/stop sequencing

Operating Temperature-40°C to 70°C(-40°F to 158°F)

Dimensions 210×150×60 mm

3.Advantages and Features

Precision Control:Delivers±0.1%speed accuracy and rapid response to load changes.

Dual-Mode Operation:Switches between programming(configuration)and operating(real-time control)modes.

Fault Tolerance:Includes over/under-voltage,overtemperature,and short-circuit protection.

Flexible Integration:Works with WOODWARD’s I/H converters to convert electrical signals to hydraulic actuation.

Remote Monitoring:Supports Modbus connectivity for remote diagnostics and system optimization.

4.Application Areas and Case Studies

Power Generation:Controls steam turbines in thermal power plants.

Oil&Gas:Manages compressor trains in refineries and pipelines.

Industrial Processes:Regulates rotating equipment in manufacturing facilities.

Case Study:

A WOODWARD 5441-693 installed in a 50 MW steam turbine power plant reduced start-up time by 25%and improved load stability,achieving a 99.8%operational uptime over 12 months.

5.Competitive Comparison

Compared to similar controllers,the 5441-693 offers:

Higher Voltage Flexibility:Supports both low-and high-voltage inputs without additional adapters.

Integrated Safety Features:Combines speed control and protective shutdown capabilities in one unit.

Cost-Effective Maintenance:Reduces downtime with modular replaceable components.

6.Selection Recommendations

System Compatibility:Verify voltage requirements and communication protocols with existing WOODWARD systems.

Environment:Ensure compliance with temperature and humidity conditions at the installation site.

Scalability:Pair with WOODWARD’s 505E or 505H systems for advanced load-sharing functionality.

7.Precautions

Installation:Follow wiring diagrams to prevent phase mismatches;use shielded cables for analog signals.

Calibration:Perform regular checks of voltage/current outputs to maintain accuracy.

Software Updates:Keep firmware up-to-date via WOODWARD’s LeoPC software.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide