Description

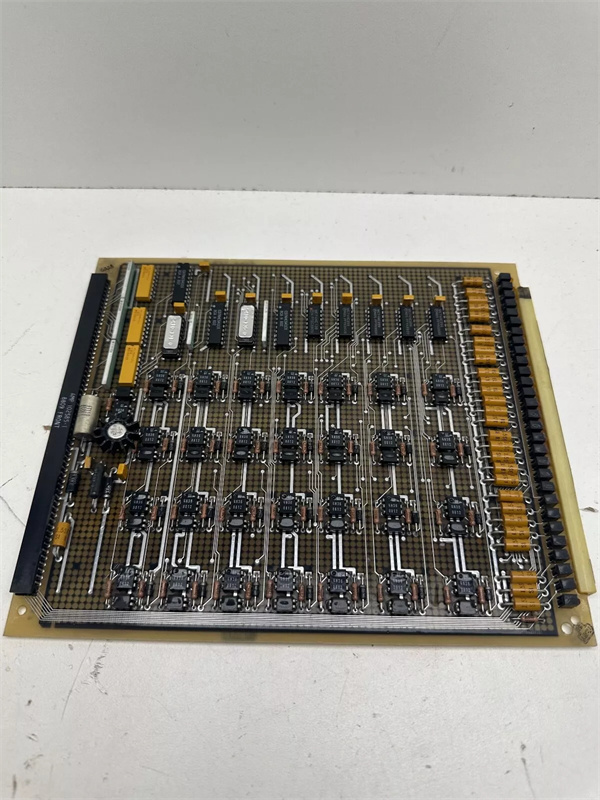

Woodward 5461-650 Temperature/Current Input Module

1. Product DescriptionThe

Woodward 5461-650 is a high-precision temperature and current input module designed for industrial automation systems. It converts sensor signals into standardized outputs for seamless integration with PLC and DCS systems, ensuring reliable performance in critical applications such as machinery control, energy management, and process automation. With advanced signal processing capabilities, this module supports a wide range of input types, including thermocouples, RTDs, and 4–20 mA current signals, making it versatile for diverse industrial environments.

2. Key Technical Parameters

| Parameter |

Specification |

| Module Type |

Temperature/Current Input Module |

| Input Voltage |

12 V DC |

| Input Signal Range |

-10 to +10 V (analog), 4–20 mA (current) |

| Resolution |

13-bit (analog inputs), 11-bit (analog outputs) |

| Accuracy |

±0.5% of full scale |

| Communication Protocol |

RS-485 (Modbus RTU) |

| Output Type |

Digital (6 transistors, 2 relays) |

| Operating Temperature |

-40°C to +85°C |

| Dimensions |

105 mm × 45 mm × 17 mm |

| Weight |

0.2 kg |

| Certifications |

UL, CE, CSA |

3. Advantages and Features

- Wide Environmental Range: Operates reliably in extreme temperatures (-40°C to +85°C), making it suitable for harsh industrial settings.

- High Precision: 13-bit analog input resolution ensures accurate measurements for critical control systems.

- Flexible Connectivity: Supports multiple input types (thermocouples, RTDs, 4–20 mA) and Modbus RTU for easy integration with automation networks.

- Robust Design: IP65/IP67-rated enclosure (depending on variant) protects against dust and moisture.

- Low Power Consumption: ≤5 W operation reduces energy costs in long-term use.

-

WOODWARD 5461-650

4. Application Areas and Use Cases

- Energy Generation: Monitors temperature and current in gas turbines and generators.

- Manufacturing: Controls machinery in automotive assembly lines and metal processing plants.

- Chemical Processing: Manages temperature-sensitive reactions in reactors.

- HVAC Systems: Optimizes climate control in large industrial facilities.

Example Case: A European automotive factory deployed the 5461-650 to monitor engine temperatures in robotic welding stations, reducing downtime by 15% due to early fault detection.

5. Competitor Comparison

Compared to similar modules, the 5461-650 offers:

- Extended temperature range (-40°C to +85°C vs. typical -20°C to +70°C).

- Higher input resolution (13-bit vs. 12-bit in many alternatives).

- Dual communication support (RS-485 and Modbus RTU) for broader system compatibility.

6. Selection Recommendations

- Input Requirements: Verify compatibility with sensor types (e.g., thermocouple/RTD) and signal ranges.

- Environmental Needs: Choose IP67 variants for wet or dusty environments.

- System Integration: Ensure RS-485/Modbus RTU compatibility with existing controllers.

- Cost Efficiency: Balances upfront cost with long-term reliability (MTBF > 50,000 hours).

7. Precautions

- Installation: Follow wiring diagrams to avoid voltage spikes. Use shielded cables for signal integrity.

- Calibration: Perform annual recalibration to maintain accuracy.

- Safety: Disconnect power before servicing. Ensure compliance with NEC/CE standards.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

Woodward 5461-650 and other automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide