Description

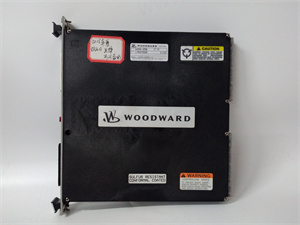

Woodward 5461-002 Digital Microprocessor Controller for Steam Turbines

The

Woodward 5461-002 is a microprocessor-based controller designed for steam turbine applications, specifically engineered to automate speed and load control in single or dual actuator configurations. As part of Woodward’s renowned 505 control system, the

5461-002 operates in two modes: programming mode for parameter configuration and operating mode for real-time turbine management. It interfaces with Woodward’s I/H converters to convert electrical signals into hydraulic commands, adjusting the main steam valve opening to maintain precise turbine speed. This compact, rugged unit supports integration with Woodward governors (e.g., 505E, 505C) and third-party systems, making it ideal for power generation, petrochemical, and industrial process plants.

| Parameter |

Specification |

| Input Voltage |

100–240 VAC (generator voltage sensing) |

| Power Supply |

12–32 VDC |

| Frequency Range |

45–65 Hz |

| Control Accuracy |

±0.1% speed regulation |

| Output Signals |

4–20 mA analog (actuator control), relay outputs |

| Communication |

USB (configuration), optional Modbus RTU |

| Operating Temperature |

-20°C to +70°C (-4°F to +158°F) |

| Dimensions |

263 × 58 × 28 mm (10.35 × 2.28 × 1.10 in) |

| Certifications |

CE, UL/cUL |

- Dual-Mode Flexibility: Configurable programming and operating modes enable tailored control for varying turbine types (gas, steam, or diesel).

- High Precision: Maintains ±0.1% speed accuracy under dynamic load changes.

- Wide Compatibility: Works with Woodward’s TG, PG, and UG series governors, as well as third-party actuators.

- Remote Monitoring: USB connectivity supports parameter adjustments and diagnostics via Woodward’s Toolkit software.

- Fault Tolerance: Built-in over/under-voltage, over-speed, and reverse power protection.

- Power Generation: Optimizes steam turbine performance in thermal power plants.

- Oil & Gas: Controls compressor turbines in refineries and offshore platforms.

- Manufacturing: Ensures stable speed for critical machinery in steel and chemical industries.

Case Study:

A Middle Eastern petrochemical plant reduced turbine downtime by 25% using the 5461-002, achieving smoother load transitions and 15% energy savings.

- Superior Integration: Seamless compatibility with Woodward’s comprehensive control ecosystem (e.g., 505E, 505H).

- Cost-Effective Retrofit: Direct replacement for older 505 series models without hardware modifications.

- Advanced Diagnostics: Real-time monitoring and alarm history simplify maintenance.

- Actuator Type: Choose dual actuator models for high-power turbines requiring redundant control.

- Communication Needs: Opt for Modbus RTU variant for SCADA integration.

- Environment: Use standard 5461-002 in general conditions; upgrade to extended-temperature models for extreme climates.

- Wiring: Ensure proper PT/CT connections to avoid signal interference.

- Calibration: Regularly verify hydraulic actuator response using Woodward’s test procedures.

- Software Updates: Keep firmware current via Toolkit software to access new features.

- Installation: Mount in a vibration-free enclosure with adequate ventilation.

声明山西鑫业达国际贸易有限公司 is your trusted partner for

Woodward 5461-002 and steam turbine solutions. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide