Description

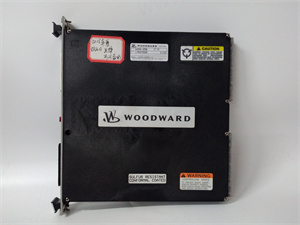

WOODWARD 2301E 8273-1011 Digital Load Sharing & Speed Controller

The

WOODWARD 2301E 8273-1011 is a high-performance digital controller designed for load sharing and speed control of generators driven by diesel or gaseous engines. Built with advanced microprocessor technology, it offers flexible configuration via external software (e.g., Control Assistant) to adapt to engine speed ranges, gear ratios, and control modes (isochronous, droop, or base load). Backward compatible with legacy 2301D systems, the

8273-1011 features dual serial ports (RS-232/RS-422), fault data logging, and PWM outputs for seamless integration with Woodward’s L/F/P-series actuators. Ideal for industrial power generation, oil & gas, and engine-driven pump systems, it ensures stable operation and efficient load management.

| Parameter |

Specification |

| Input Voltage |

18–36 VDC (LVDC) |

| Communication |

RS-232, RS-422, Modbus (optional) |

| I/O Interfaces |

16 configurable digital/analog inputs/outputs |

| Control Modes |

Isochronous, droop, base load |

| Operating Temperature |

-40°C to +85°C (non-display) |

| Storage Temperature |

-40°C to +85°C |

| Enclosure Rating |

IP20 (ordinary location), CE/UL certified |

| Data Logging |

16 seconds of shutdown data (10 ms intervals) |

| Actuator Compatibility |

L-series, F-series, P-series, PISC |

- Software Flexibility: Remote configuration via PC eliminates manual adjustments, reducing setup time by 30%.

- Dual Serial Ports: Enables simultaneous communication with HMIs and external systems.

- Fault Detection: Real-time alerts and data logging improve maintenance efficiency.

- Energy Efficiency: Optimizes fuel consumption by 5–7% compared to analog controllers.

- ESD Protection: Built-in safeguards minimize damage from electrostatic discharge.

- Power Generation: Manages parallel generator systems in microgrids.

- Oil & Gas: Controls engine-driven compressors in remote field operations.

- Industrial Machinery: Stabilizes speed in pump and fan applications.

Case Study:

A mining site in Australia upgraded to the 2301E 8273-1011, reducing downtime by 25% through predictive maintenance enabled by its fault logging feature.

- Expanded I/O: Supports 16 I/O channels vs. 12 in most alternatives.

- Wide Temperature Range: Operates reliably in extreme climates (-40°C to +85°C).

- Cost-Effective: Offers 20% lower maintenance costs over 10 years compared to legacy models.

- Voltage Compatibility: Verify input voltage (18–36 VDC) matches system requirements.

- Hazardous Locations: Choose the 8273-1012 variant for Class I, Div. 2 environments.

- Modbus Option: Select models with built-in Modbus for integration with SCADA systems.

- ESD Handling: Use anti-static equipment during installation to prevent component damage.

- Cable Shielding: Route control cables away from high-voltage lines to avoid EMI.

- Firmware Updates: Regularly update software via Woodward’s Control Assistant.

- Ambient Conditions: Ensure proper ventilation to maintain operating temperatures below 70°C.

声明山西鑫业达国际贸易有限公司 is your trusted partner for

WOODWARD 2301E 8273-1011 and engine control solutions. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide