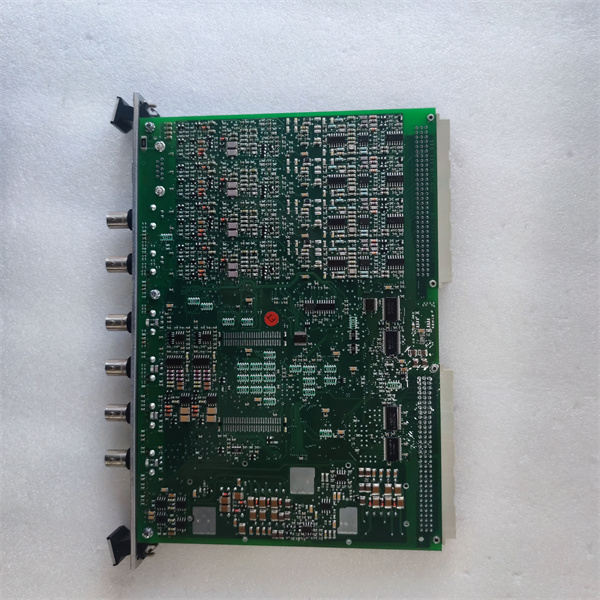

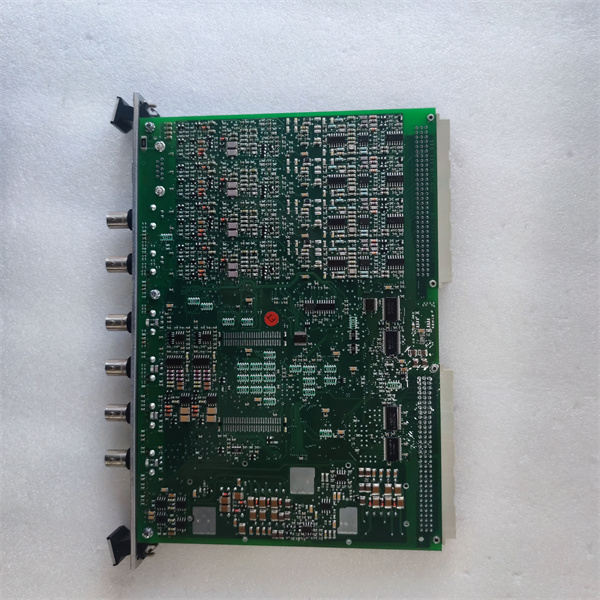

Description

VIBRO-METER VM600 MPC4 is a high-performance machinery protection card designed for real-time vibration monitoring and fault diagnosis of rotating equipment in critical industrial environments. As a core component of the VM600 series Machinery Protection System (MPS), it provides advanced signal processing, multi-channel measurement, and programmable alarm capabilities to ensure the reliability and safety of turbines, compressors, pumps, and other rotating machinery.

The

VM600 MPC4 combines

4 dynamic signal channels and

2 speed (tachometer) channels to monitor vibration, displacement, velocity, and phase reference signals simultaneously. Its modular design allows integration with VM600 racks (e.g., ABE040, ABE042) and compatibility with a wide range of sensors, including accelerometers, eddy current probes, and proximity sensors. The card supports

programmable filters (wideband/narrowband) and

adaptive alarm thresholds, enabling precise detection of mechanical faults such as unbalance, misalignment, and bearing damage.

Key features include:

- DSP Technology: Real-time signal processing for accurate analysis of vibration patterns.

- Hot-Swappable Design: Replaceable without system shutdown, reducing maintenance downtime.

- Safety Certifications: Available in SIL versions (IEC 61508) for safety-critical applications.

- Multi-Protocol Communication: Supports RS-232/RS-485 and integrates with MODBUS TCP/PROFIBUS DP via VM600 CPUR2/IOCR2 rack controllers.

| Parameter |

Specification |

| Input Channels |

4 dynamic (±10 VAC) + 2 speed (TTL/reluctance/eddy current) |

| Frequency Range |

0.5 Hz to 10 kHz (dynamic), 0–500 Hz (speed) |

| Sampling Rate |

Up to 51.2 kHz per channel |

| Resolution |

16-bit ADC for high-precision measurements |

| Outputs |

4 configurable DC outputs (4–20 mA/0–10 V), 4 relays (alarm/trip) |

| Power Supply |

24 VDC (±10%), 5.5 W power consumption |

| Operating Temperature |

-20°C to 60°C (standard), -40°C to 85°C (extended) |

| Dimensions |

210 mm × 170 mm × 75 mm (8.27″ × 6.69″ × 2.95″) |

| Certifications |

CE, RoHS, IEC 61000-4-2 (ESD), IEC 61000-4-4 (EFT) |

VM600 MPC4

-

Multi-Channel Monitoring:

- Simultaneously tracks vibration, displacement, and speed across 6 channels, providing comprehensive equipment health assessment.

- Example: In a petrochemical plant, the VM600 MPC4 detected a bearing fault in a compressor 72 hours before a critical failure, saving $300,000 in downtime costs.

-

Advanced Signal Processing:

- Digital filters eliminate noise and enhance fault signature detection.

- Phase analysis identifies misalignment and resonance issues with ±0.1° accuracy.

-

Rugged Design:

- Withstands extreme temperatures (-20°C to 60°C) and vibrations (IEC 60068-2-6), suitable for offshore rigs and power plants.

-

Safety Compliance:

- SIL-certified versions ensure compliance with functional safety standards in oil/gas and nuclear industries.

- Power Generation: Monitors steam turbines and generators for vibration-induced failures.

- Oil & Gas: Protects compressors and pumps in offshore platforms and refineries.

- Manufacturing: Enhances CNC machine tool reliability through predictive maintenance.

Case Study:

A wind farm integrated VM600 MPC4 into its turbine monitoring system. The card’s real-time vibration analysis reduced unplanned downtime by 40% by detecting gearbox issues before catastrophic failure.

| Feature |

VM600 MPC4 |

Typical Competitors |

| Channels |

4 dynamic + 2 speed |

2–4 channels |

| Temperature Range |

-20°C to 60°C |

0°C to 50°C |

| Safety Certification |

SIL-compliant |

Optional add-ons |

| Sampling Rate |

51.2 kHz |

25–50 kHz |

| Integration |

Native MODBUS/PROFIBUS support |

Requires additional modules |

VM600 MPC4

- Channel Requirements:

- Choose the VM600 MPC4 for applications needing 4+ dynamic channels (e.g., multi-bearing turbines).

- Safety Needs:

- Opt for SIL versions in hazardous environments (e.g., chemical plants).

- Communication:

- Pair with CPUR2/IOCR2 rack controllers for MODBUS TCP/PROFIBUS DP connectivity.

- Environmental Conditions:

- Verify temperature and vibration resistance matches site requirements.

-

Installation:

- Use anti-static wrist straps to avoid ESD damage.

- Ensure proper grounding and shielded cables to minimize EMI interference.

-

Operation:

- Do not exceed input voltage limits (24 VDC ±10%).

- Monitor LED indicators for sensor faults or signal anomalies.

-

Maintenance:

- Clean cooling vents quarterly to prevent overheating.

- Update firmware via VIBRO-METER’s official channels for security patches.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for VM600 MPC4 and other automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide