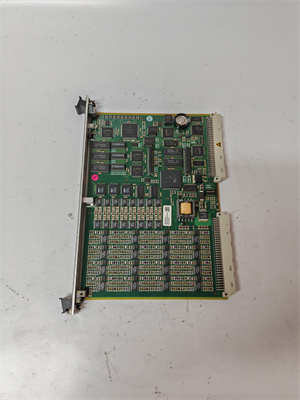

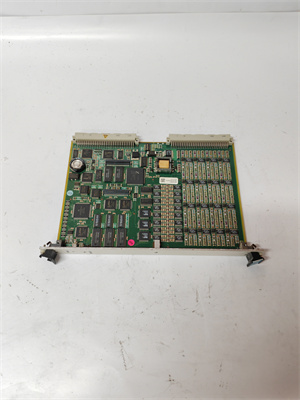

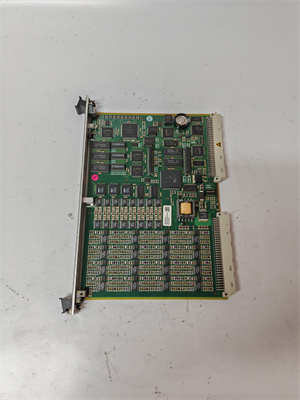

Description

VIBRO-METER VM600 CMC16 is a high-performance 16-channel condition monitoring card designed for advanced machinery protection and state monitoring systems. Engineered to integrate seamlessly with VIBRO-METER’s VM600 series racks, this module serves as the central data acquisition and analysis hub for real-time vibration, temperature, and process parameter monitoring in industrial environments. With support for industry-standard protocols like Modbus RTU/TCP and PROFINET, the VM600 CMC16 ensures reliable communication between field devices, host software (e.g., VibroSight®), and third-party systems.

The

VM600 CMC16 acts as the core component of VIBRO-METER’s VM600 machinery protection system (MPS) and state monitoring system (CMS). It interfaces with input/output modules (e.g., IOC16T, IOC4T) and protection cards (e.g., MPC4, AMC8) to process raw sensor data, execute advanced signal conditioning, and transmit critical insights to operators. Key features include:

- 16 individually configurable dynamic channels for vibration, temperature, and process parameter monitoring.

- 24-bit ADC resolution with 0.005% linearity accuracy, ensuring precise measurement of 微小振动 (e.g., 0.1 µm displacement) and process parameters.

- Real-time FFT analysis (up to 3200 lines) for early detection of machinery defects like misalignment or bearing wear.

- Programmable anti-aliasing filters and galvanic isolation to minimize electromagnetic interference (EMI) in harsh industrial environments.

- Dual communication paths (Ethernet and RS-485) for flexible integration with DCS, PLC, or SCADA systems.

The module’s VMEbus interface enables high-speed data transfer to the VM600 CPU module, while its hot-swappable design allows seamless component replacement without system downtime.

| Parameter |

Specification |

| Input Channels |

16 dynamic (vibration/process) + 4 tachometer/speed reference |

| Output Channels |

4 digital outputs (relay or analog) + 32 open collector outputs (jumper-selectable) |

| Power Supply |

24V DC ±10% (derived from VM600 rack) |

| Communication |

Modbus RTU/TCP, PROFINET, Ethernet (100 Mbps), RS-232/422/485 |

| Signal Resolution |

24-bit ADC with 0.005% linearity accuracy |

| Sampling Rate |

Up to 98 kHz (per channel, configurable) |

| Frequency Range |

0.16 Hz to 20 kHz (dynamic inputs) |

| Input Types |

AC/DC voltage (0.1–20 V FSD), current (4–20 mA), thermocouples (61.022 mV FSD) |

| Environmental |

Operating temperature: -10°C to 60°C; Storage: -40°C to 85°C |

| Dimensions |

233.4 mm x 160 mm x 25.4 mm (6U VME form factor) |

| Weight |

0.5 kg |

VM600 CMC16

-

High-Precision Data Acquisition:

- 24-bit resolution ensures accurate measurement of 微小振动 (e.g., 0.1 µm displacement) and process parameters.

- Low noise floor (<0.1 mV RMS) enables detection of early machinery defects.

-

Versatile Signal Conditioning:

- Supports AC/DC voltage, current, thermocouples, and strain gauge inputs with selectable ranges (e.g., 0.1 V to 20 V FSD for AC measurements).

- Built-in anti-aliasing filters and amplifiers reduce signal distortion.

-

Robust Environmental Performance:

- EMI/RFI protection and galvanic isolation shield against electrical noise in industrial settings.

- Operates in extreme temperatures (-10°C to 60°C) and withstands vibrations up to 5 g.

-

Efficient System Integration:

- Plug-and-play compatibility with VM600 racks and MPC4 modules reduces setup time.

- Dual communication paths: VMEbus for real-time data transfer and Ethernet for remote configuration via VibroSight® software.

Industry Applications:

- Energy: Condition monitoring of turbines, generators, and compressors in power plants.

- Oil & Gas: Real-time vibration analysis of offshore drilling equipment and pumps.

- Manufacturing: Predictive maintenance of motors, conveyor systems, and CNC machines.

- Aerospace: Structural health monitoring of aircraft engines and landing gear.

Case Study:

A power plant integrated the VM600 CMC16 into its turbine monitoring system. By analyzing vibration data from 16 accelerometers and 4 temperature sensors, the module detected early signs of misalignment in a critical turbine shaft. Real-time alerts triggered maintenance actions, preventing a potential failure that could have caused $1.5 million in downtime costs.

| Feature |

VM600 CMC16 |

Typical Competitors |

| Resolution |

24-bit (0.005% accuracy) |

16–20-bit (0.1% accuracy) |

| Channels |

16 dynamic + 4 tachometer |

8–12 dynamic + 2–4 tachometer |

| EMI Protection |

Built-in isolation and filtering |

Optional add-ons |

| Software Integration |

Native support for VibroSight® |

Proprietary or third-party software required |

| Environmental Range |

-10°C to 60°C |

0°C to 50°C |

VM600 CMC16

-

System Compatibility:

- Ensure your VM600 rack supports VMEbus and the MPC4/AMC8 protection cards.

- Verify sensor types (e.g., accelerometers, thermocouples) match the module’s input specifications.

-

Performance Requirements:

- Choose the VM600 CMC16 for high-resolution vibration analysis in large-scale systems.

- Opt for lower-channel modules (e.g., IOC4T) if budget or space is constrained.

-

Environmental Fit:

- Confirm operating temperature (-10°C to 60°C) aligns with your industrial environment.

- Use surge protectors in high-noise areas to enhance EMI resistance.

-

Installation:

- Use ESD-safe tools and grounding straps to prevent static damage.

- Secure the module in the VM600 rack with screws to avoid physical damage during operation.

-

Operation:

- Avoid exceeding input voltage/current limits to prevent hardware failure.

- Calibrate sensors and the module annually using VIBRO-METER’s recommended procedures.

-

Maintenance:

- Clean connector pins quarterly with isopropyl alcohol to remove oxidation.

- Update firmware via VibroSight® to access new features and bug fixes.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for VM600 CMC16 and other industrial automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide