Description

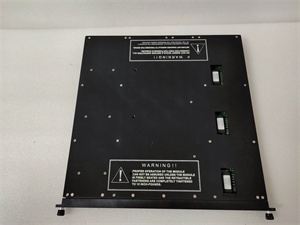

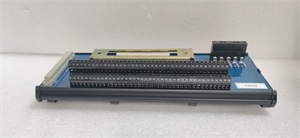

The

TRICONEX T8850 is a high-performance

Tricon CX Digital Input Module designed for safety-critical industrial automation systems. As a key component of the Triconex Triplex® architecture, the

T8850 provides reliable monitoring of binary input signals from field devices such as switches, sensors, and relays. Built with TRICONEX’s renowned triple modular redundancy (TMR) technology, the

T8850 ensures fault tolerance and continuous operation in harsh environments. It supports 32 isolated input channels, each capable of detecting 24 VDC signals, and integrates seamlessly with Tricon CX controllers to deliver real-time data for critical control and safety applications.

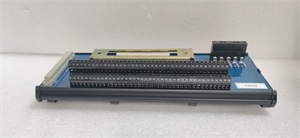

| Parameter |

Specification |

| Model |

T8850 |

| Type |

Digital Input Module (Tricon CX Series) |

| Channels |

32 isolated channels |

| Input Voltage |

24 VDC (16–30 VDC tolerance) |

| Signal Type |

Binary (ON/OFF), sinking/sourcing compatible |

| Isolation |

Optically isolated (500 VAC between channels and ground) |

| Redundancy |

Triple Modular Redundancy (TMR) |

| Operating Temperature |

-40°C to +70°C |

| Dimensions |

133 mm x 68 mm x 23 mm (W x H x D) |

| Weight |

0.6 kg |

| Compatibility |

Tricon CX controllers, Triconex I/O systems |

TRICONEX T8850

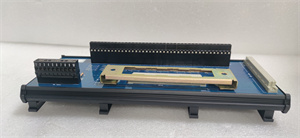

- TMR Redundancy for Unmatched Reliability: The triple modular redundancy design provides self-diagnostic capabilities with >99% fault coverage, ensuring system integrity even during single or dual channel failures. For example, in a petrochemical plant, the T8850 maintained full functionality during a simulated channel fault, preventing false trips and production downtime.

- High-Speed Signal Processing: Processes input signals with a response time <10 ms, critical for real-time safety interlocks and emergency shutdown (ESD) systems.

- Rugged Industrial Design: Withstands extreme vibrations (2 g, 5–2000 Hz), shock (15 g, 11 ms), and electromagnetic interference (EMI/EMC compliance per IEC 61000), making it suitable for offshore platforms, power plants, and heavy machinery.

- Hot-Swappable Design: Enables maintenance without system shutdown, reducing downtime and improving operational efficiency.

- Application Areas:

- Oil and gas (wellhead control, pipeline monitoring)

- Power generation (turbine protection, boiler safety systems)

- Chemical and petrochemical (reactor interlocks, batch process control)

- Manufacturing (robotics safety circuits, conveyor system monitoring)

- Application Case: A major LNG facility deployed the TRICONEX T8850 to monitor 28 safety switches on cryogenic pumps. The module’s TMR redundancy and fast fault detection allowed the system to accurately identify a faulty sensor without triggering a false ESD event, saving over $500,000 in potential production losses during a year of operation.

Compared to similar digital input modules in the market, the T8850 distinguishes itself through its TMR architecture, which offers higher fault tolerance than dual-redundancy alternatives. Its 32-channel density reduces panel space requirements by 30% compared to legacy designs, while advanced diagnostics provide real-time health status updates, minimizing troubleshooting time. The module’s wide temperature range and robust isolation also outperform standard industrial modules in extreme environments.

TRICONEX T8850

- System Compatibility: Ensure the module is paired with Tricon CX controllers or compatible Triconex I/O chassis to leverage full redundancy and communication features.

- Channel Requirements: Assess the number of input signals (e.g., safety switches, limit sensors) and ensure the 32-channel capacity meets current and future needs.

- Environmental Demands: Verify that the module’s temperature, vibration, and EMI ratings align with your facility’s conditions, especially for outdoor or high-risk zones (e.g., Zone 1/Class I Div 1).

- Scalability: Consider future expansion plans; the T8850 supports seamless integration with TRICONEX’s broader I/O portfolio for scalable safety systems.

- Wiring Practices: Use shielded twisted-pair cables to minimize noise, and follow TRICONEX guidelines for grounding and polarity to avoid signal errors.

- Voltage Compliance: Ensure input voltage remains within 16–30 VDC to prevent damage or false readings.

- Hot Swap Procedures: Always use the module’s ejector levers during replacement to avoid physical damage, and ensure the system is in a safe state before accessing live components.

- 定期维护: Perform quarterly health checks via the Tricon CX software to monitor channel diagnostics and replace faulty modules proactively.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for industrial automation solutions. We offer the

TRICONEX T8850 and a comprehensive range of TRICONEX spare parts, backed by technical support and genuine product warranties. Visit

www.xydcontrol.com or contact us today to explore how the T8850 can enhance your system’s safety and reliability.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide