Description

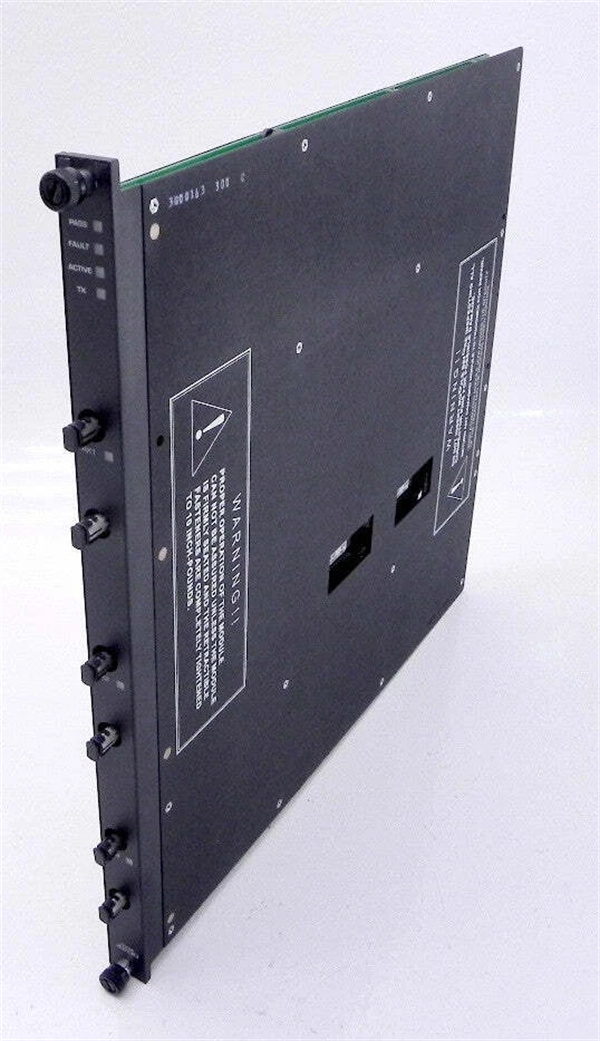

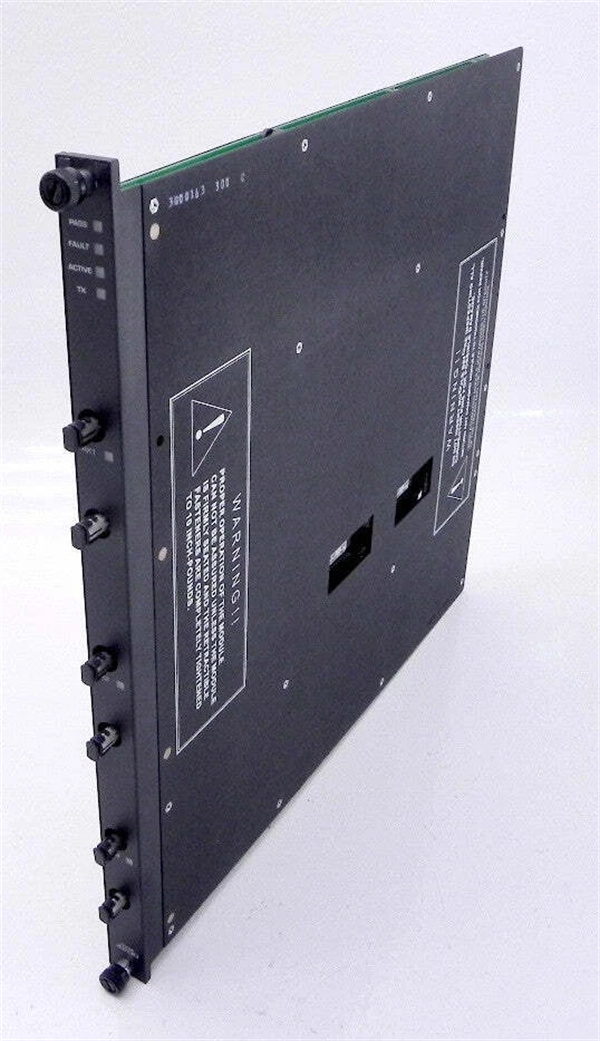

TRICONEX RXM4200 is a high-performance relay output module designed to deliver reliable and safe switching capabilities in critical industrial control systems. As a key component of TRICONEX’s triple modular redundant (TMR) platform, the

RXM4200 is engineered to meet the stringent requirements of safety-critical applications, ensuring secure actuation of final control elements even in the presence of faults. This module is ideal for applications requiring precise control of discrete outputs, such as motor starters, valves, alarms, or circuit breakers, while adhering to international safety standards like IEC 61508 and ISA 84.00.07. The

TRICONEX RXM4200 enables seamless integration into TMR architectures, providing unmatched availability and diagnostic accuracy for industrial processes.

| Parameter |

Description |

| Module Type |

Relay Output Module (SPDT, Form A Contacts) |

| Number of Channels |

16 channels |

| Switching Voltage |

24 VDC to 250 VAC |

| Switching Current |

Up to 5 A per channel |

| Contact Material |

Silver alloy for low resistance and long life |

| Redundancy Support |

Fully compatible with TMR architecture |

| Safety Integrity Level |

SIL 3 (certified per IEC 61508) |

| Operating Temperature |

-40°C to +70°C |

| Dimensions |

178 mm (H) x 48 mm (W) x 231 mm (D) |

| Diagnostics |

Channel-level fault detection (contact failure, coil open, overcurrent) |

RXM4200

The TRICONEX RXM4200 is distinguished by its triple modular redundancy (TMR) design, which ensures fault tolerance by voting on signals across three independent channels, preventing single-point failures. Its high-duty-cycle relays are rated for over 1 million operations, making them suitable for frequent switching applications. The module’s hot-swappable design allows for replacement without system shutdown, minimizing downtime, while its comprehensive diagnostics provide real-time status updates on contact health and coil integrity.

A key advantage is its SIL 3 certification, making it suitable for safety instrumented systems (SIS) in high-risk industries. The RXM4200 also offers rapid response times (typically <10 ms), ensuring timely actuation for critical control actions, and its wide voltage range accommodates both low- and high-power applications.

The TRICONEX RXM4200 is widely deployed in industries such as petrochemicals, pharmaceuticals, mining, and aviation, where reliable discrete output control is essential. It is commonly used to interface with emergency shutdown (ESD) systems, boiler control units, and machinery interlock systems.

Case Study: In a pharmaceutical manufacturing plant, the RXM4200 module was integrated into a TMR-based SIS to control sterilization chamber valves. During a routine process, the module detected a failing relay contact via its diagnostics, allowing maintenance teams to replace the channel without halting production. This proactive intervention prevented a potential batch loss valued at $200,000 and ensured compliance with FDA regulations.

Compared to standard relay output modules, the TRICONEX RXM4200 excels in safety integrity and system integration. Its built-in TMR architecture eliminates the need for external redundancy components, reducing hardware complexity and cabling costs. The module’s advanced diagnostics and SIL 3 certification offer a higher level of safety assurance than non-TMR alternatives, while its compatibility with TRICONEX controllers streamlines configuration and troubleshooting compared to multi-vendor solutions.

RXM4200

When selecting the TRICONEX RXM4200, consider the following:

- Load Requirements: Ensure the module’s voltage and current ratings match the connected devices (e.g., solenoids, contactors).

- Environmental Demands: Verify compatibility with temperature, vibration, and moisture levels in your operational environment.

- Redundancy Strategy: Assess whether TMR architecture aligns with your system’s availability and fault-tolerance goals.

- Diagnostic Needs: Prioritize the module’s ability to provide detailed health reports for predictive maintenance planning.

- Arc Suppression: Use appropriate snubbers or surge protectors for inductive loads to extend relay life and prevent voltage spikes.

- Wiring Guidelines: Follow TRICONEX’s recommended wiring practices to ensure proper grounding and minimize electromagnetic interference (EMI).

- Firmware Management: Regularly update the module’s firmware to address security vulnerabilities and optimize performance.

- Hot-Swap Safety: Always use approved tools and follow lockout/tagout (LOTO) procedures when servicing the module in live systems.

- Contact Maintenance: Periodically inspect relay contacts for wear, especially in high-switching-frequency applications, to maintain reliability.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide