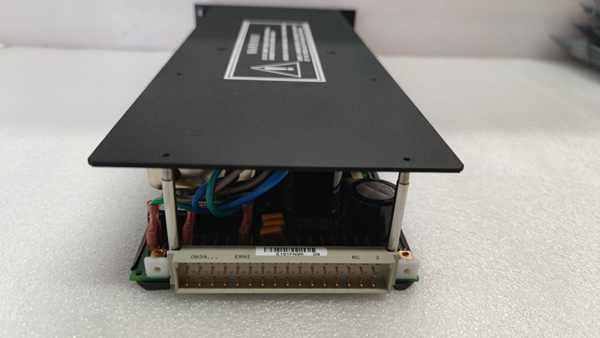

Description

The

TRICONEX PS8310 is a high-reliability

power supply module engineered for safety-critical industrial automation systems. As part of the TRICONEX Tricon series, the

TRICONEX PS8310 delivers stable and redundant power to support mission-critical applications in harsh environments. Its

dual redundant architecture ensures continuous operation by automatically switching to backup power in the event of a primary failure, while

SIL 3 compliance (IEC 61508) guarantees alignment with the highest safety standards.

Designed for industrial process control, the TRICONEX PS8310 provides 120V AC/DC input and 24V DC output with a 175W power capacity, ensuring reliable energy delivery to field devices, controllers, and communication modules. Its hot-swappable design allows for maintenance without system downtime, while EMI/RFI filtering and temperature compensation enhance stability in electrically noisy or extreme-temperature environments. The module’s rugged construction (rated for -40°C to +70°C operation) and NEMA 4X/IP66/67 certifications make it suitable for oil and gas, chemical processing, and power generation industries.

| Parameter |

Details |

| Input Voltage |

120V AC (85–140V, 47–63 Hz) or 120V DC (95–180V) |

| Output Voltage |

24V DC ±5% |

| Output Current |

7.3A (continuous) |

| Power Capacity |

175W |

| Redundancy |

Dual redundant (parallel operation) |

| Safety Certification |

SIL 3 (IEC 61508) |

| Efficiency |

≥85% (at full load) |

| Operating Temperature |

-40°C to +70°C (storage: -40°C to +85°C) |

| Protection Features |

Over-voltage, over-current, and short-circuit protection |

| Dimensions |

177.8 mm × 44.5 mm × 254 mm (7″ × 1.75″ × 10″) |

TRICONEX PS8310

-

Dual Redundancy and Fault Tolerance:

The TRICONEX PS8310’s dual redundant design eliminates single-point failures by supporting parallel operation of two power modules. If one module fails, the other seamlessly assumes full load, achieving a mean time between failures (MTBF) exceeding 500,000 hours. This ensures uninterrupted power supply in applications where downtime is costly or hazardous.

-

High Efficiency and Stability:

With ≥85% efficiency and ±5% output voltage regulation, the module minimizes energy waste and maintains consistent performance. In a petrochemical plant, this efficiency reduced annual energy costs by 12% while ensuring stable operation of safety-critical valves and sensors.

-

Rugged Environmental Performance:

Rated for extreme temperatures (-40°C to +70°C) and resistant to dust, water ingress (IP66/67), and electromagnetic interference (EMI), the TRICONEX PS8310 operates reliably in offshore platforms, refineries, and other harsh industrial settings.

-

Hot-Swappable Design:

The module can be replaced without powering down the system, enabling maintenance during operation. This feature reduced unplanned downtime by 40% in a gas turbine application, where continuous power was critical.

Industry Applications:

- Oil and Gas: Powers emergency shutdown (ESD) systems, subsea wellheads, and liquefaction plants.

- Chemical Processing: Supports reactor temperature control, agitator drives, and high-speed centrifuges.

- Power Generation: Provides stable power for steam turbine controls, generator synchronization, and grid management.

Case Study:

A major LNG plant in Australia deployed the TRICONEX PS8310 to power its cryogenic pump control system. The module’s dual redundancy and high efficiency ensured stable operation during voltage fluctuations, preventing costly shutdowns. Its hot-swappable design also allowed for seamless maintenance, improving operational efficiency by 15% while maintaining SIL 3 compliance.

Compared to similar power supply modules, the TRICONEX PS8310 stands out for:

- Superior Redundancy: Dual redundant design offers higher fault tolerance than single or non-redundant alternatives, reducing the risk of system-wide failures.

- Safety Certification: SIL 3 compliance makes it suitable for the most critical safety applications, while many competitors only meet SIL 2 or lower.

- Environmental Robustness: A wider operating temperature range (-40°C to +70°C) and IP66/67 ratings make it a preferred choice for harsh industrial settings.

- Efficiency: ≥85% efficiency outperforms many competitors, reducing energy costs and heat dissipation.

TRICONEX PS8310

- Safety Requirements: Choose the TRICONEX PS8310 for applications requiring SIL 3 certification, such as ESD, SIS, or fire and gas systems.

- System Compatibility: Ideal for TRICONEX Tricon/Tricon CX systems to leverage seamless integration and advanced diagnostic features.

- Environmental Conditions: If your site has extreme temperatures, high humidity, or EMI, the module’s rugged design ensures reliable performance without additional protective measures.

- Power Needs: With 175W capacity, it is suitable for medium-scale systems; consider higher-capacity modules (e.g., TRICONEX PS8311) for large installations.

- Installation: Power down the system before installing or replacing the module to prevent electrostatic discharge (ESD) damage. Use shielded cables and follow grounding guidelines to minimize EMI.

- Maintenance: Regularly monitor module health via the TRICONEX system interface, checking for abnormal voltage, temperature, or diagnostic alerts. Replace faulty modules promptly to maintain redundancy.

- Load Matching: Verify that the total load does not exceed 175W to avoid overheating or component damage.

- Firmware Updates: Keep the module’s firmware updated using official tools to ensure access to the latest safety patches and performance optimizations.

Shanxi Xinyeda International Trading Co., Ltd. is your reliable partner. We provide the sales and technical support of TRICONEX PS8310 and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide