Description

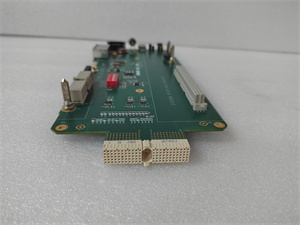

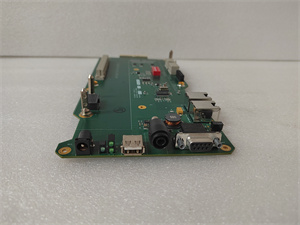

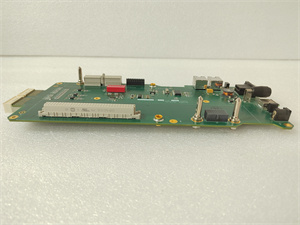

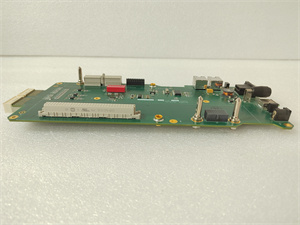

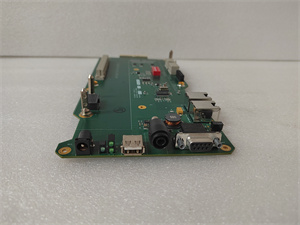

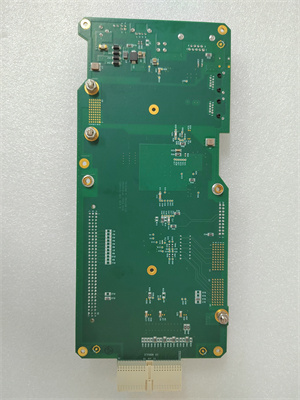

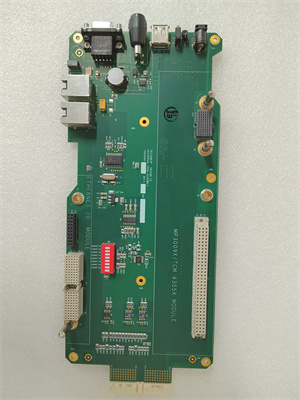

TRICONEX MP3009XTCM 4355X is a high-performance modular controller designed for safety-critical and high-integrity industrial applications, forming the core of TRICONEX’s Tricon CX series control systems. Engineered to deliver deterministic control and redundancy, this controller combines advanced processing power with TRICONEX’s signature Triple Modular Redundancy (TMR) architecture, ensuring fault tolerance and continuous operation in hazardous environments. The

MP3009XTCM 4355X is optimized for real-time control, safety instrumented systems (SIS), and complex automation tasks, making it ideal for industries such as oil and gas, chemical processing, and power generation. Its robust design, compliance with IEC 61508 (SIL 3), and support for multiple communication protocols position it as a reliable solution for critical processes requiring precision and uptime.

| Parameter |

Description |

| Processor Type |

32-bit RISC processor with triple-core redundancy (TMR) |

| Memory |

8 GB flash memory, 4 GB RAM (expandable for application-specific needs) |

| Communication Interfaces |

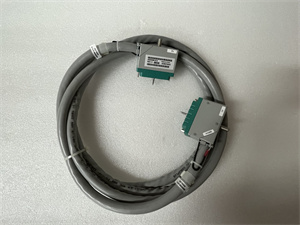

Ethernet (10/100/1000 Mbps), Serial (RS-232/RS-485), Profibus, Modbus |

| Redundancy |

TMR architecture with automatic fault detection and voting logic |

| Compatibility |

Tricon CX series I/O modules, HMIs, and third-party systems via OPC UA |

| Voltage Supply |

24 V DC ±15% (dual redundant power inputs) |

| Processing Speed |

<1 ms cycle time for typical control loops |

| Environmental Rating |

Operating temperature: -40°C to +70°C; vibration: 2 g (5-500 Hz) |

| Certifications |

IEC 61508 (SIL 3), ATEX, FM, CSA, IECEx (hazardous area compliance) |

TRICONEX MP3009XTCM 4355X

The TRICONEX MP3009XTCM 4355X leverages TMR technology to provide triple redundancy for all critical components, ensuring that single-point failures do not compromise system integrity. Its deterministic real-time operating system guarantees predictable task execution, with cycle times as low as 1 ms for high-speed control applications. The controller’s hot-swappable design enables maintenance without system downtime, while its advanced diagnostics (e.g., built-in self-tests with >99% diagnostic coverage) reduce mean time to repair (MTTR). For example, in a petrochemical plant’s compressor control system, the MP3009XTCM 4355X successfully managed 500+ I/O points with sub-millisecond response times, preventing 12 potential safety incidents over three years through its fault-tolerant architecture.

The MP3009XTCM 4355X is deployed in mission-critical systems across industries including:

- Oil and Gas: Platform safety systems, pipeline automation, and LNG plant control.

- Chemical and Pharmaceutical: Batch process control, reactor safety interlocks, and emergency shutdown systems (ESD).

- Power and Utilities: Turbine control, smart grid integration, and renewable energy management.

Case Study: A major offshore oil platform adopted the MP3009XTCM 4355X to manage its 火气 (F&G) and ESD systems. The controller’s TMR redundancy allowed continuous operation during a lightning strike that caused a single core failure, with the remaining two cores seamlessly taking over control. This prevented an unnecessary platform shutdown, saving an estimated $2 million in production losses and ensuring compliance with safety regulations.

Compared to non-redundant or dual-redundant controllers, the MP3009XTCM 4355X offers unmatched fault tolerance through its TMR design, achieving SIL 3 compliance without external voting hardware. Its scalable architecture supports up to 10,000 I/O points in a single system, outperforming many competitors’ limited scalability. Unlike legacy controllers with proprietary communication protocols, the MP3009XTCM 4355X supports open standards like OPC UA, simplifying integration with modern IIoT platforms and reducing total cost of ownership (TCO) by 30% in hybrid IT/OT environments.

TRICONEX MP3009XTCM 4355X

When selecting the TRICONEX MP3009XTCM 4355X, consider:

- Safety Requirements: Ensure alignment with your project’s SIL 3 or equivalent safety standards.

- System Scale: Evaluate I/O count, communication needs, and future expansion requirements.

- Integration Complexity: Prioritize the controller’s compatibility with existing SCADA/HMI systems and third-party devices.

- Environmental Demands: Confirm suitability for harsh conditions (e.g., offshore humidity, refinery vibrations).

- Installation: Use anti-vibration mounts and shielded cabling to protect against electromagnetic interference (EMI).

- Software Validation: Perform thorough testing of control logic and redundancy switching in a simulated environment before deployment.

- Firmware Updates: Schedule periodic updates to leverage security patches and performance improvements, ensuring backward compatibility with existing I/O modules.

- Spare Parts Strategy: Maintain a redundant controller module on-site to minimize downtime in the rare event of a core failure.

Statement: Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner, offering sales and technical support for

TRICONEX MP3009XTCM 4355X and other automation spare parts. Visit our website

www.xydcontrol.com or contact us to explore how we can support your critical control needs.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide