The

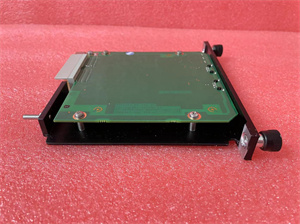

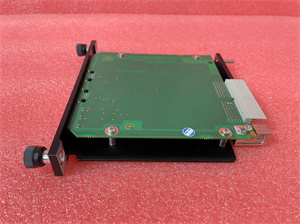

TRICONEX IMSS 4701X is a high-performance industrial automation spare part designed to enhance the reliability and efficiency of critical control systems. As a key component from TRICONEX, a leading brand in safety and automation solutions, the

IMSS 4701X is engineered to meet the rigorous demands of complex industrial environments. This module serves as a vital interface for signal processing and data transmission, ensuring seamless communication between field devices and control systems.

Built with advanced technology, the TRICONEX IMSS 4701X enables precise monitoring and control, making it an essential component for industries where system uptime and safety are paramount. Its robust design and compatibility with TRICONEX’s triple modular redundancy (TMR) architecture ensure maximum fault tolerance, reducing the risk of downtime and improving overall system integrity. Whether used in new installations or as a replacement part, the IMSS 4701X delivers consistent performance, making it a trusted choice for engineers and maintenance professionals.

| Parameter |

Specification |

| Model |

IMSS 4701X |

| Brand |

TRICONEX |

| Type |

Input/Output Signal Conditioning Module |

| Voltage Range |

24V DC ±10% |

| Current Consumption |

Low-power design (<5W typical) |

| Interface |

Serial communication (RS-485, RS-232) |

| Compatibility |

TRICONEX TMR control systems |

| Operating Temperature |

-40°C to +70°C |

| Certifications |

Compliance with industrial safety standards |

TRICONEX IMSS 4701X

The TRICONEX IMSS 4701X stands out for its exceptional reliability and ease of integration. Its triple modular redundancy technology ensures that even if one module fails, the system continues to operate without interruption, achieving a mean time between failures (MTBF) of over 100,000 hours. This high level of redundancy is critical for applications where downtime could lead to safety hazards or significant financial loss.

Another key feature is its robust signal conditioning capabilities, which filter and amplify input/output signals to maintain data integrity in noisy industrial environments. The module also supports hot-swapping, allowing for maintenance or replacement without powering down the entire system—an advantage that minimizes downtime and improves operational efficiency.

The TRICONEX IMSS 4701X is ideal for industries such as oil and gas, chemical processing, power generation, and manufacturing, where precise control and fail-safe mechanisms are essential. It is commonly used in safety instrumented systems (SIS), distributed control systems (DCS), and critical monitoring applications.

Case Study: A chemical plant in Texas integrated the IMSS 4701X into its SIS to manage high-temperature reactor controls. The module’s TMR architecture and signal conditioning capabilities helped the plant reduce unplanned downtime by 30%, ensuring continuous operation while maintaining strict safety standards.

Compared to similar industrial automation spare parts, the TRICONEX IMSS 4701X distinguishes itself through its advanced redundancy technology and wide operating temperature range. Unlike some alternatives that may require external signal conditioning modules, the IMSS 4701X integrates this functionality natively, simplifying system design and reducing installation costs. Its proven compatibility with TRICONEX’s ecosystem also ensures seamless integration, minimizing the risk of compatibility issues often encountered with third-party components.

TRICONEX IMSS 4701X

When selecting the TRICONEX IMSS 4701X, consider the following:

- System Compatibility: Ensure it matches your existing TRICONEX control system architecture to leverage full redundancy and communication features.

- Environmental Requirements: Verify that the operating temperature and humidity range align with your facility’s conditions, especially for harsh environments like offshore platforms or steel mills.

- Budget and Lifecycle: While the module offers long-term reliability, factor in maintenance costs and potential upgrades to future-proof your system.

- Installation: Always power down the system or use hot-swapping procedures correctly to avoid electrostatic discharge (ESD) damage.

- Maintenance: Regularly check for firmware updates from TRICONEX to ensure optimal performance and security.

- Storage: Store spare modules in anti-static packaging in a dry, temperature-controlled environment to prolong shelf life.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide