Description

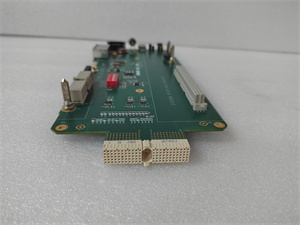

TRICONEX DI3301 is a high-performance digital input module designed for safety-critical industrial automation systems. As a core component of TRICONEX’s triple modular redundancy (TMR) platform, the

DI3301 securely acquires discrete input signals from field devices such as sensors, switches, and interlocks. Engineered to meet the rigorous demands of industries requiring zero downtime, this module features triplicated channels and advanced fault detection, ensuring reliable signal processing even in the presence of single-channel failures. The

DI3301 is SIL 3 (IEC 61508) certified, making it ideal for applications in oil and gas, petrochemical, and power sectors where safety and precision are paramount.

| Parameter |

Details |

| Module Type |

Digital Input Module (Sinking/Sourcing) |

| Channels |

16 isolated channels |

| Input Voltage |

24 VDC ±10% |

| Filter Time |

Adjustable (1–100 ms) |

| Redundancy |

TMR architecture with built-in voting and diagnostics |

| Safety Certification |

SIL 3 (IEC 61508), TÜV certified |

| Operating Temperature |

-40°C to +70°C |

| Hot-Swap Capability |

Yes (online replacement without system disruption) |

| Diagnostics |

Real-time channel status monitoring (open/short circuit, overvoltage) |

TRICONEX DI3301

The TRICONEX DI3301 excels in fault tolerance through its TMR design, which provides a diagnostic coverage rate exceeding 99%. This ensures that any single-channel anomaly—such as a wiring fault or signal distortion—is identified and isolated, preventing false system trips. For example, in a chemical plant’s emergency shutdown system, the module’s redundancy successfully ignored a transient noise spike in one channel while maintaining accurate readings from the two healthy channels.

The module’s hot-swappable design minimizes operational downtime, allowing technicians to replace faulty units without powering down the system—a feature that reduces maintenance time by up to 75%. Its adjustable input filtering also enhances resilience in high-noise environments, such as near rotating machinery, by suppressing electromagnetic interference (EMI) and ensuring clean signal acquisition.

The DI3301 is widely used in industries requiring robust safety and reliability, including:

- Oil and Gas: Monitoring valve positions, pressure switches, and emergency stop signals in offshore platforms.

- Power Generation: Capturing breaker states and turbine control signals in combined cycle power plants.

- Manufacturing: Interfacing with safety 光幕 and machine status sensors in automated production lines.

Case Study: A major LNG terminal integrated the DI3301 into its safety instrumented system (SIS) to monitor 20+ safety switches on cryogenic pumps. During a routine test, the module’s diagnostics detected a gradual decline in signal integrity on one channel, enabling proactive maintenance before a potential failure. This prevented a costly shutdown and ensured compliance with international safety standards.

Compared to conventional digital input modules, the DI3301 offers superior safety integrity with its SIL 3 certification and TMR architecture, reducing the probability of dangerous failures on demand (PFD) by over 90% compared to non-redundant designs. Its extended temperature range and rugged construction also outperform many alternatives, eliminating the need for additional environmental protection in harsh industrial settings.

TRICONEX DI3301

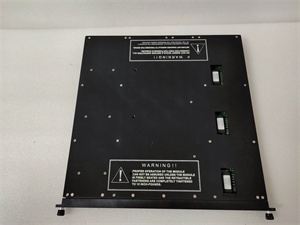

When specifying the DI3301, consider:

- Signal Compatibility: Ensure field devices output 24 VDC signals compatible with the module’s sinking/sourcing configuration.

- Safety Requirements: Confirm the module’s SIL 3 rating aligns with your system’s safety integrity level (SIL) requirements.

- Environmental Factors: Evaluate temperature, humidity, and EMI levels at the installation site to ensure optimal performance.

- System Integration: Verify compatibility with TRICONEX controllers and network architectures for seamless redundancy management.

- Cabling Practices: Use shielded, twisted-pair cables and follow TRICONEX’s grounding guidelines to minimize signal interference.

- Voltage Verification: Regularly check input voltage levels to avoid damage from voltage fluctuations outside the specified range.

- Filter Configuration: Adjust filter times based on signal dynamics; shorter filters (e.g., 5 ms) for fast-acting sensors and longer filters (e.g., 50 ms) for noisy environments.

- ESD Protection: Handle the module with anti-static equipment to prevent electrostatic discharge (ESD) damage to internal circuitry.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide