Description

The

TRICONEX 9761-210 is a high-reliability

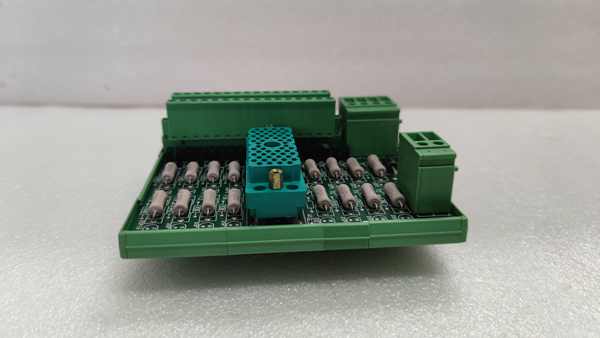

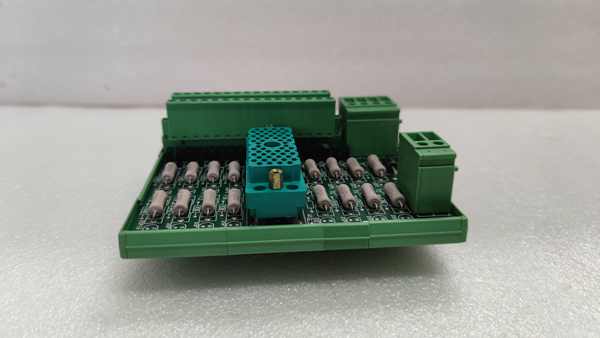

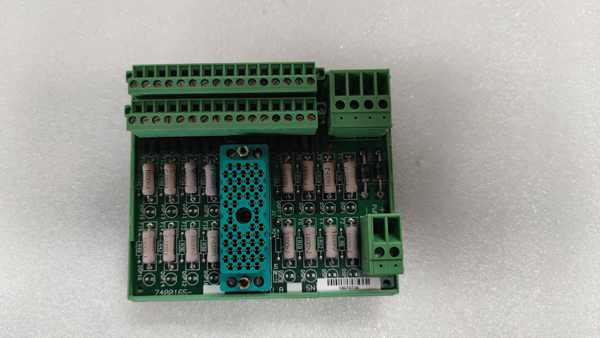

analog input module designed for safety-critical industrial control systems, serving as a core component of TRICONEX’s triple modular redundancy (TMR) architecture. Engineered to acquire and process analog signals from field devices such as sensors and transmitters, the

9761-210 supports multiple signal types, including 4–20 mA current, 0–5 VDC voltage, thermocouples (TC), and resistance temperature detectors (RTD). Its robust design ensures precise signal conversion, fault tolerance, and compliance with international safety standards like IEC 61508 (SIL 3), making it ideal for applications in oil & gas, chemical processing, and power generation where accurate and reliable data acquisition is non-negotiable.

| Parameter |

Specification |

| Module Type |

Analog Input Module (16 channels, differential) |

| Signal Types |

4–20 mA, 0–5 VDC, 0–10 VDC, TC (J/K/T types), RTD (Pt100) |

| Resolution |

16-bit ADC with ±0.1% full-scale accuracy |

| Redundancy |

TMR architecture with self-diagnostic capabilities |

| Isolation |

Galvanic isolation (2500 VDC between channels) |

| Sampling Rate |

<100 ms per channel (configurable) |

| Operating Temperature |

-40°C to +70°C |

| Safety Certification |

IEC 61508 (SIL 3), IEC 61511 (SIS) |

| Compatibility |

TRICONEX Tricon controllers and I/O systems |

| Dimensions |

178 mm (H) × 48 mm (W) × 231 mm (D) |

TRICONEX 9761-210

- TMR Redundancy for Fault Tolerance: The 9761-210 uses three independent signal processing channels with voting logic to detect and isolate single-point failures, ensuring continuous operation. For example, in a refinery’s temperature monitoring system, the module maintained accurate readings even when one channel experienced a transient fault, preventing false alarms and production disruptions.

- Multi-Signal Flexibility: Supports a wide range of industrial signals, reducing the need for multiple module types. This flexibility was demonstrated in a chemical plant where the module seamlessly integrated with both pressure transmitters (4–20 mA) and thermocouples (J-type) in a single system.

- Advanced Diagnostics: Built-in self-tests monitor channel health, detecting issues like open circuits, short circuits, and signal drift with >99% fault coverage. This feature helped a power plant identify a failing RTD sensor before it caused a turbine trip, saving over $150,000 in potential downtime.

- Hot-Swappable Design: Allows module replacement without system shutdown, minimizing maintenance time and improving operational efficiency.

- Application Areas:

- Oil & gas (wellhead control, pipeline pressure monitoring)

- Power generation (turbine temperature control, boiler safety systems)

- Chemical/petrochemical (reactor process control, batch processing)

- Application Case: A pharmaceutical manufacturer deployed the TRICONEX 9761-210 to monitor sterilization chamber conditions (temperature and pressure) in a TMR-based SIS. The module’s high accuracy and redundancy ensured compliance with FDA regulations, while its diagnostics prevented a batch failure by alerting operators to a faulty pressure sensor mid-cycle.

Compared to standard analog input modules, the 9761-210 offers superior safety integrity (SIL 3 certification) and diagnostic depth, making it suitable for high-risk applications. Its TMR architecture provides higher fault tolerance than dual-redundant designs, while its multi-signal support reduces hardware complexity compared to single-function modules. The module’s wide temperature range and EMI resistance also outperform non-industrial-grade alternatives in harsh environments.

TRICONEX 9761-210

- Signal Compatibility: Ensure the module supports your sensor’s output type (e.g., RTD wiring configuration: 2-wire, 3-wire, or 4-wire).

- Safety Requirements: Prioritize SIL 3 certification for critical processes to meet functional safety standards.

- Environmental Fit: Verify temperature, vibration, and humidity ratings for your operational environment, especially for outdoor or high-EMI zones.

- Scalability: Assess channel density (16 channels) against current and future I/O needs to avoid over-provisioning or under-capacity.

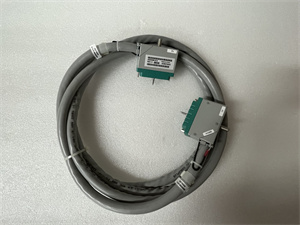

- Wiring Practices: Use shielded twisted-pair cables for analog signals and follow TRICONEX guidelines for grounding to minimize interference.

- Calibration: Periodically calibrate the module with traceable standards to maintain measurement accuracy, especially for TC and RTD inputs.

- Firmware Updates: Keep the module’s firmware updated to leverage the latest diagnostic improvements and security patches.

- Hot Swap Safety: Always use the module’s ejector levers during replacement and ensure the system is in a safe state to avoid transient errors.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner. We provide the

TRICONEX 9761-210 and a full range of TRICONEX automation spare parts, backed by technical support and genuine product warranties. Visit

www.xydcontrol.com or contact us to explore how this module can enhance your system’s reliability and safety.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide