Description

The

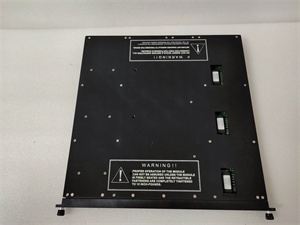

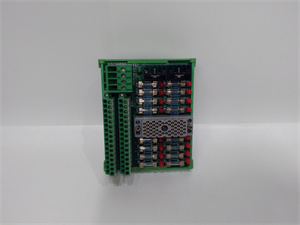

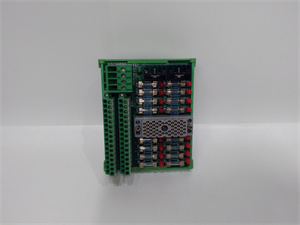

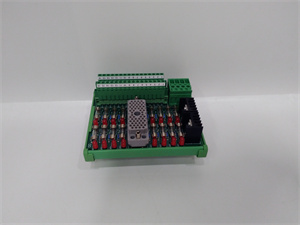

TRICONEX 9662 – 810 is a digital output module designed for safety – critical industrial control systems. It is an integral part of the Triconex safety instrumented system (SIS). This module is used to control final control elements such as motors and actuators. It features a plug – in design, which allows for easy replacement. With its dual – redundancy design, the TRICONEX 9662 – 810 ensures that the system can continue to operate even if one module fails. In addition, it supports various communication protocols, enabling seamless integration with other systems.

- Power Supply: 24 VDC

- Power Consumption: 20 W

- Operating Temperature: – 40 °C to 70 °C

- Storage Temperature: – 55 °C to 85 °C

- Weight: 0.5 kg

- Dimensions: 133 x 68 x 23 mm

- Output Type: Sink – type, capable of 1 A per channel and 10 A in total

- Signal Type: 24 V DC binary (ON/OFF)

- Redundancy: Dual – redundancy with self – diagnostic capabilities

- Compatibility: Compatible with TRICONEX Triplex® controllers such as Tricon CX and Tricon EX

TRICONEX 9662-810

- High Reliability: The dual – redundancy design and built – in diagnostics with high fault coverage (over 99%) ensure the reliable operation of the module. For example, in a chemical plant, the module’s redundancy design prevented unintended valve closure during a single – channel fault, avoiding production downtime.

- Easy Integration: It supports various communication protocols, making it easy to integrate with other systems in the industrial control network.

- Rugged Design: Withstand harsh environments, including high vibration, temperature fluctuations, and electromagnetic interference, making it suitable for applications in offshore platforms, heavy machinery, and other demanding environments.

- Application Areas: The TRICONEX 9662 – 810 is widely used in industries such as oil and gas, power generation, chemical, and petrochemical. It is used to control emergency shutdown valves, pumps, compressors, circuit breakers, turbine trip systems, reactor safety interlocks, and batch process valves.

- Application Case: In a refinery, the TRICONEX 9662 – 810 was integrated into the TMR safety system to control 12 critical ESD valves. During a simulated fault test, the module’s fast response time (< 25 ms) and fault – detection capabilities allowed the system to safely shut down a leaking pipeline within 100 ms, preventing a potential hazardous release.

Compared with similar products in the market, the TRICONEX 9662 – 810 stands out for its high – reliability dual – redundancy design, excellent fault – detection capabilities, and wide range of communication protocol support. These features enable it to better meet the requirements of safety – critical industrial control systems and ensure the stable operation of the entire system.

TRICONEX 9662-810

- Compatibility: Ensure that the module is compatible with your existing TRICONEX Triplex® controllers and other equipment in the control system.

- Output Requirements: Confirm that the sink – type output and current capacity (1 A per channel, 10 A total) meet the needs of your field devices, such as solenoid valves and contactors.

- Environmental Conditions: Consider the operating environment of the module, including temperature, humidity, and electromagnetic interference, to ensure that it can operate reliably in your specific application.

- Budget: While considering the performance and reliability of the module, also take into account your budget constraints to ensure that the selected product provides the best value for money.

- Wiring: Use shielded cables to reduce interference and follow TRICONEX’s guidelines for positive/negative polarity and grounding.

- Load Limits: Do not exceed the maximum current rating of 1 A per channel or 10 A total to avoid overheating or damage to the module.

- Hot Swapping: Power down the system before replacing the module to prevent transient voltage spikes.

- Maintenance: Perform regular diagnostic checks, at least once a year, to ensure the functionality of the channels and the integrity of the isolation.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for the TRICONEX 9662 – 810 and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide