Description

The

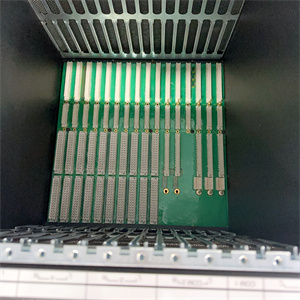

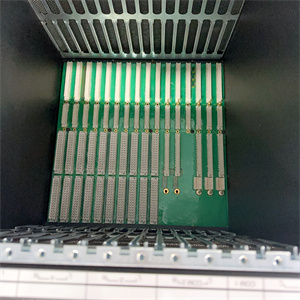

TRICONEX 8120E is a high-reliability input/output (I/O) module designed for safety-critical industrial automation systems. Engineered by Invensys TRICONEX, a leader in fault-tolerant control solutions, the

TRICONEX 8120E serves as a vital component for ensuring precise data transmission and system stability in demanding environments. This module is specifically built to handle analog input signals, converting real-world sensor data into digital information that control systems can process efficiently.

Ideal for applications requiring stringent safety and availability, the TRICONEX 8120E supports seamless integration with TRICONEX’s triple modular redundancy (TMR) architecture, enhancing system fault tolerance. Its robust design minimizes downtime by incorporating advanced self-diagnostic features, making it a trusted choice for industries where operational continuity is non-negotiable. Whether used in process control, safety instrumented systems (SIS), or complex machinery automation, the TRICONEX 8120E delivers accurate signal conditioning and reliable performance, ensuring optimal system responsiveness.

| Parameter |

Details |

| Module Type |

Analog Input Module (AI) |

| Signal Types |

Voltage (0-5V, 0-10V), Current (4-20mA), Thermocouple, RTD |

| Channels |

16 isolated channels |

| Resolution |

16-bit |

| Input Range |

Programmable per channel |

| Accuracy |

±0.1% of full-scale range |

| Operating Voltage |

24V DC (±10%) |

| Power Consumption |

<5W |

| Communication Interface |

TRICONEX proprietary backplane bus |

| Temperature Range |

-40°C to +70°C (operating); -40°C to +85°C (storage) |

| Compatibility |

TRICONEX Tricon systems, including Tricon CX and Tricon EX platforms |

TRICONEX 8120E

The TRICONEX 8120E stands out for its exceptional reliability and adaptability. Its TMR architecture ensures that even if one channel experiences a fault, the module continues operating using redundant channels, achieving a mean time between failures (MTBF) of over 500,000 hours. This high level of fault tolerance reduces the risk of unplanned shutdowns, a critical benefit for industries where downtime translates to significant losses.

Another key feature is its wide signal compatibility, supporting multiple input types without requiring hardware modifications. This flexibility allows engineers to configure the module for diverse applications, from monitoring temperature via RTDs to measuring process pressure with 4-20mA sensors. The module’s advanced diagnostics continuously monitor channel health, providing real-time status updates to facilitate proactive maintenance and rapid issue resolution.

The TRICONEX 8120E is widely used in industries such as oil and gas, chemical processing, power generation, and manufacturing, where safety and precision are paramount. It excels in applications that involve continuous data acquisition from analog sensors, including pressure transmitters, temperature probes, and flow meters.

A notable application case involves a large petrochemical plant that integrated the TRICONEX 8120E into its SIS. The module was used to monitor critical process variables in a distillation column, ensuring accurate data transmission to the control system. By leveraging the module’s TMR technology and self-diagnostics, the plant achieved a 30% reduction in sensor-related faults and improved overall system availability, demonstrating the module’s effectiveness in high-stakes environments.

Compared to similar I/O modules in the market, the TRICONEX 8120E distinguishes itself through its combination of high-channel density, broad signal compatibility, and robust fault tolerance. While some alternatives may offer basic analog input capabilities, few match its ability to operate reliably in extreme temperatures or integrate seamlessly with TMR architectures. Its advanced self-diagnostic features and long MTBF also set it apart, providing users with a balance of performance, durability, and ease of maintenance.

TRICONEX 8120E

When selecting the TRICONEX 8120E, consider the following factors:

- Compatibility: Ensure it aligns with your existing TRICONEX control system architecture to avoid integration issues.

- Signal Requirements: Verify that the module supports the specific analog signals (voltage, current, thermocouple, etc.) used in your application.

- Environmental Conditions: Confirm that the operating temperature and humidity ranges match your installation environment, especially for harsh industrial settings.

- Scalability: Evaluate whether the 16-channel configuration meets your current and future I/O needs, balancing performance with cost-efficiency.

To ensure optimal performance and safety:

- Installation: Follow electrostatic discharge (ESD) precautions during handling and installation to prevent component damage.

- Configuration: Use TRICONEX’s approved software tools to program input ranges and calibration parameters accurately.

- Maintenance: Schedule regular health checks using the module’s diagnostic features and replace faulty channels promptly to maintain system redundancy.

- Safety Compliance: Ensure the module is part of a properly validated safety loop that meets industry standards such as IEC 61508 or ISA 84.00.07.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide