Description

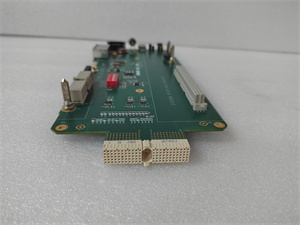

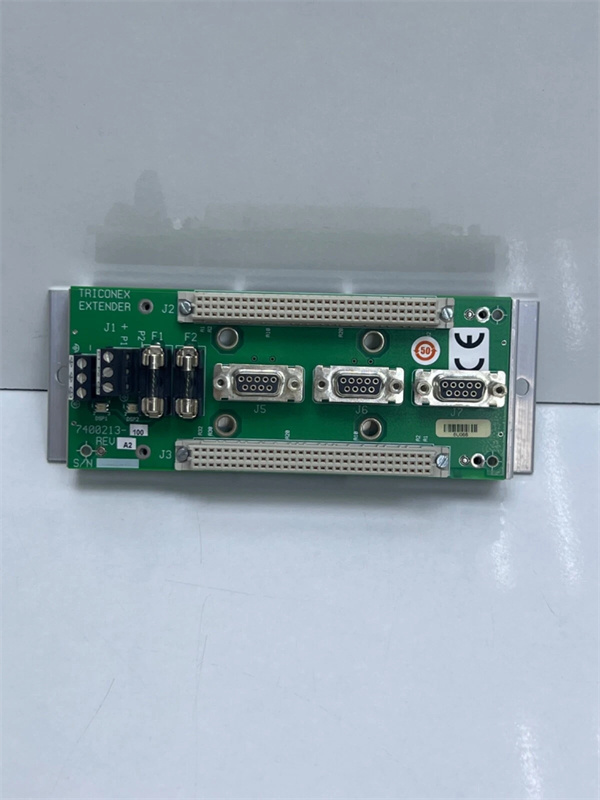

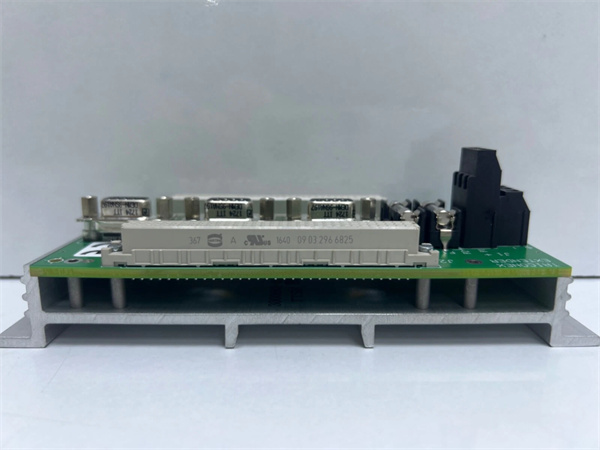

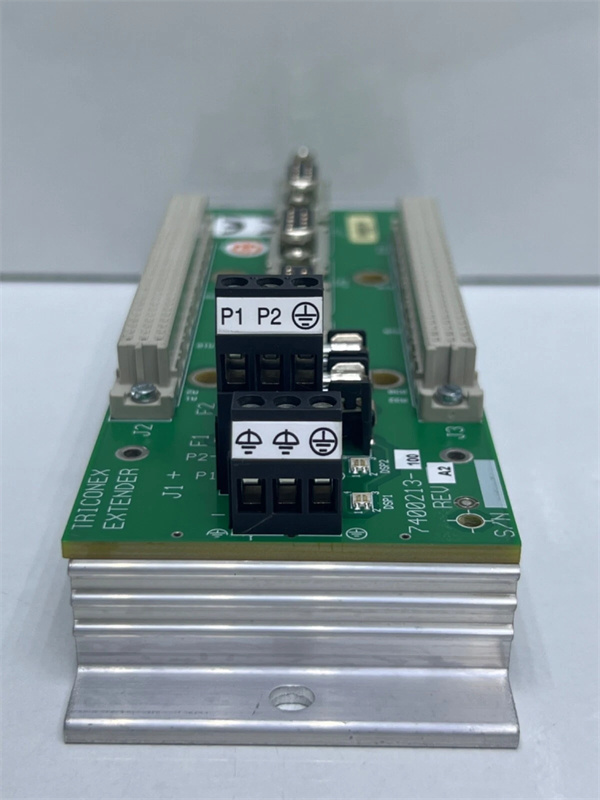

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Industrial Control Module |

| Operating Voltage | 24 VDC |

| Input Current | ≤5 mA (communication module) / 100 mA (other functions) |

| Communication Protocols | Modbus RTU, Ethernet/IP |

| Output Type | Relay contact |

| Maximum Load Capacity | 1 A |

| Signal Compatibility | RS – 485, Modbus RTU |

| Operating Temperature Range | – 20 °C to + 70 °C (communication module) / – 40 °C to + 75 °C (other functions) |

| Storage Temperature Range | – 40 °C to + 85 °C |

| Relative Humidity | 0% to 95% non-condensing |

| Isolation | 2,000 VRMS |

| Compatibility | TRICONEX RTU systems and other industry-standard devices |

TRICONEX 7400213-100

3. Advantages and Characteristics

- High Reliability: Constructed with top-quality materials and a rugged design, the TRICONEX 7400213-100 can endure extreme industrial conditions, including harsh temperatures, dust, and humidity. Its advanced error-detection and correction algorithms, coupled with comprehensive protection features, significantly reduce the risk of network errors and equipment damage. In fact, in a long-term operation in a chemical plant, the module maintained stable operation with a mean time between failures (MTBF) exceeding 200,000 hours, ensuring the uninterrupted operation of the production process.

- Excellent Compatibility: The module’s support for multiple communication protocols and a variety of input/output channels enables seamless integration with a broad spectrum of TRICONEX RTU systems and other industry-standard devices. This makes it easy to expand and upgrade the system as per the evolving requirements, saving both time and cost in system integration.

- Ease of Installation and Maintenance: Thanks to its user-friendly interface and compact design, the TRICONEX 7400213-100 is straightforward to install and maintain. In a large-scale manufacturing facility, the installation process was completed within a short time, and routine maintenance tasks can be carried out efficiently, minimizing system downtime and enhancing overall work efficiency.

4. Application Areas and Application Cases

-

Industry Applications:

- Oil and Gas: The TRICONEX 7400213-100 is widely used in oil and gas production for applications such as wellhead monitoring, pipeline control, and offshore platform automation. It can transmit real-time data on parameters like pressure, flow rate, and temperature, enabling operators to make informed decisions promptly.

- Power Generation: In power plants, it plays a crucial role in turbine control, generator protection, and substation automation systems. By ensuring reliable communication between various components, it contributes to the stable generation and distribution of electricity.

- Chemical Processing: For chemical plants, the module is utilized in processes like reactor control, chemical dosing, and safety interlock systems. It helps in maintaining precise control over chemical reactions and ensuring the safety of the production environment.

- Pharmaceutical Manufacturing: In pharmaceutical facilities, it is used for monitoring and controlling critical processes such as drug synthesis, sterilization, and packaging. Its reliability ensures the quality and consistency of pharmaceutical products.

-

Case Study: In an oil refinery, the TRICONEX 7400213-100 was employed to connect numerous field sensors, including pressure sensors and flow meters, to the central control system. Through its high-speed and reliable communication protocols, it transmitted real-time data on the oil pipeline’s status, such as pressure fluctuations and flow rates, to the control room. The control system could then monitor the refining process in real-time, making timely adjustments to maintain optimal operation. When a minor overpressure situation occurred in a pipeline section, the module’s accurate data transmission enabled the control system to quickly detect the issue and initiate corrective actions, preventing a potential major disruption and saving the refinery from significant losses.

5. Competitive Comparison

Compared to similar industrial control modules available in the market, the TRICONEX 7400213-100 stands out due to its superior reliability and stability. While some competing products may struggle to operate stably in a wide temperature range, the TRICONEX 7400213-100 can function effectively from -40 °C to +75 °C. Additionally, its extensive support for multiple communication protocols and higher data transfer efficiency give it an edge over alternatives, meeting the stringent real-time requirements of industrial control systems more effectively. Moreover, its modular design and user-friendly interface make installation and maintenance much more convenient, reducing the overall cost of ownership compared to products with complex installation and maintenance procedures.

TRICONEX 7400213-100

6. Selection Recommendations

- System Compatibility: Before choosing the TRICONEX 7400213-100, it is essential to verify its compatibility with your existing equipment and control system. Check if the communication protocols and interface types match to ensure seamless integration. Also, consider the software compatibility to avoid any issues during operation.

- Installation Environment: Evaluate the installation environment carefully, taking into account factors such as temperature, humidity, and the presence of dust or corrosive substances. Although the TRICONEX 7400213-100 is designed for harsh environments, ensuring that the actual installation conditions are within its specified operating limits will help maintain its performance and lifespan.

- Budget Considerations: While the TRICONEX 7400213-100 offers high-quality performance and reliability, it is important to consider your project budget. Compare the cost of the module with the benefits it provides, such as reduced downtime and increased operational efficiency, to determine the best value for your investment. You may also consider options for future expansion and upgrades to ensure long-term cost-effectiveness.

7. Precautions

- Installation: When installing the TRICONEX 7400213-100, strictly follow the installation instructions provided in the product manual. Ensure proper wiring connections to avoid incorrect installation that could lead to equipment damage or system malfunctions. Use anti-static wristbands or other appropriate anti-static measures to prevent electrostatic discharge from damaging the module’s internal components, especially when handling the circuit boards.

- Operation: Ensure that the power supply voltage remains stable and within the specified range of 24 VDC. Fluctuations outside this range can cause damage to the module. Avoid operating the module in environments with strong electromagnetic interference, as it can affect the accuracy and stability of data transmission. If necessary, use shielding measures to protect the module from electromagnetic fields.

- Maintenance: Regularly inspect the module for any signs of damage, loose connections, or overheating. Clean the module periodically to prevent dust and dirt from accumulating, which can affect its heat dissipation and overall performance. It is advisable to perform routine diagnostic checks to identify and address any potential issues early. Also, back up relevant data regularly to safeguard against data loss in case of unexpected equipment failures.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide