Description

The

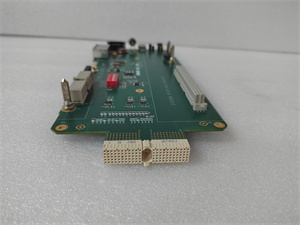

TRICONEX 3720 is a high-reliability analog input module designed for critical industrial control and safety systems. Engineered by TRICONEX, a leader in fault-tolerant automation solutions, the

TRICONEX 3720 is built to deliver precise signal acquisition and robust performance in harsh operating environments. This module serves as a vital component for industries requiring continuous monitoring and control, such as oil and gas, power generation, and chemical processing.

The TRICONEX 3720 specializes in converting analog signals from field instruments, such as sensors and transducers, into digital data usable by control systems. Its core functions include signal conditioning, isolation, and high-resolution conversion, ensuring accurate data transmission while protecting against electrical noise and transient disturbances. With its tripartite redundancy architecture, the module minimizes downtime by enabling seamless fault detection and replacement, making it an ideal choice for applications where system availability is non-negotiable.

| Parameter |

Specification |

| Module Type |

Analog Input Module (AI) |

| Channels |

16 isolated channels |

| Input Range |

4-20 mA, 0-5 V, 0-10 V, ±10 V |

| Resolution |

16-bit |

| Accuracy |

±0.1% of full scale |

| Power Supply |

24 V DC (±10%) |

| Isolation |

Galvanic isolation (500 V rms) |

| Temperature Range |

-40°C to +70°C (operating) |

| Communication Interface |

TriBus (proprietary high-speed bus) |

| Redundancy Support |

Triplicated hardware (TMR architecture) |

| Compliance |

IEC 61508 (SIL 3), NEC Class I Div 2 |

TRICONEX 3720

The TRICONEX 3720 stands out for its advanced tripartite modular redundancy (TMR), which ensures that even if one channel fails, the remaining two continue operating without interruption. This design achieves a mean time between failures (MTBF) exceeding 500,000 hours, significantly reducing maintenance needs and operational risks. The module’s built-in self-diagnostic capabilities continuously monitor signal integrity and hardware health, flagging anomalies in real time to enable proactive maintenance.

Another key feature is its wide compatibility with industry-standard analog signals, eliminating the need for custom signal conditioning modules. Its rugged construction and extended temperature range make it suitable for deployments in extreme environments, from offshore platforms to high-temperature refineries. The module also supports hot-swapping, allowing replacement without powering down the system, which is critical for maintaining uptime in 24/7 operations.

The TRICONEX 3720 is widely used in industries that demand precise process control and safety-critical monitoring, including:

- Oil and Gas: Monitoring pressure, temperature, and flow rates in upstream and downstream facilities.

- Power Generation: Controlling steam turbine parameters and boiler efficiency in thermal power plants.

- Chemical Processing: Ensuring safe reaction conditions in petrochemical reactors.

Case Study: A large petrochemical plant in the Middle East integrated the TRICONEX 3720 into its safety instrumented system (SIS) to monitor over 200 analog signals from distillation columns. The module’s TMR architecture and high-resolution conversion helped the plant achieve a 99.99% system availability rate, reducing unplanned shutdowns by 40% compared to previous solutions. Its self-diagnostics also enabled faster troubleshooting during periodic audits, streamlining compliance with international safety standards.

Compared to similar analog input modules on the market, the TRICONEX 3720 distinguishes itself through its unique combination of triplicated redundancy, wide input range flexibility, and SIL 3 certification. While many alternatives offer basic isolation and signal conversion, few match its ability to maintain full functionality during single-channel faults or operate reliably in extreme temperatures. Its seamless integration with TRICONEX’s broader control ecosystem also simplifies system design, reducing compatibility issues often encountered with multi-vendor setups.

TRICONEX 3720

When selecting the TRICONEX 3720, consider the following:

- System Compatibility: Ensure your control system supports TriBus communication and TMR architecture.

- Signal Requirements: Verify that the module’s input range matches your field instruments (e.g., 4-20 mA for transmitters).

- Environmental Needs: If deploying in harsh conditions, confirm the temperature, vibration, and corrosion resistance meet site specifications.

- Scalability: Evaluate whether the 16-channel configuration aligns with current and future monitoring needs to avoid over-provisioning or under-capacity.

- Installation: Always power down the system before installing or replacing the module, and use anti-static wrist straps to prevent ESD damage.

- Wiring: Follow shielded cable practices to minimize electromagnetic interference (EMI), and ensure proper grounding for isolated channels.

- Calibration: Perform periodic calibration checks using certified test equipment to maintain accuracy, especially after hardware changes or extreme temperature cycles.

- Firmware Management: Keep the module’s firmware updated to the latest version provided by the manufacturer to access the latest diagnostic features and safety patches.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide