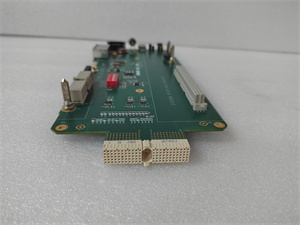

Description

The

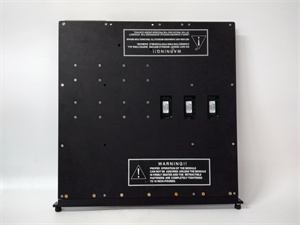

Triconex 3604E is a high-performance

Triple Modular Redundancy (TMR) digital output module engineered for safety-critical applications in industries such as oil & gas, chemical processing, and power generation. As part of Triconex’s TRICON system, this module ensures continuous operation even in harsh environments by leveraging advanced fault-tolerant technology.

The core function of the Triconex 3604E is to provide reliable control signals to actuators, valves, and other field devices. It processes output commands from the main controller through three independent channels and uses patented Quadruple Voter Circuitry to validate signals, ensuring a single, deterministic output. This design guarantees fail-safe operation and minimizes downtime in critical processes.

Key advantages of the Triconex 3604E include:

- High Availability: TMR architecture ensures system continuity even with multiple channel failures.

- Real-Time Diagnostics: Built-in diagnostics monitor each channel and detect faults within milliseconds, reducing mean time to repair (MTTR).

- Flexible Configuration: Supports 16 non-committed output points with 24V DC nominal voltage, adaptable to various industrial protocols.

| Parameter |

Specification |

| Type |

TMR Digital Output Module |

| Nominal Voltage |

24V DC (range: 22–45V DC) |

| Output Points |

16 non-committed |

| Current Rating |

2A per point (10A surge for 10ms) |

| Isolation |

1,500V DC between channels and ground |

| Operating Temperature |

-40°C to +70°C |

| Certifications |

SIL 3 (IEC 61508), ATEX, IECEx, CE |

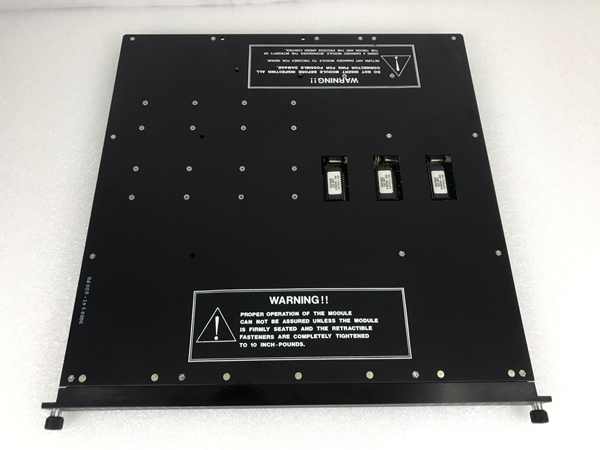

| Dimensions |

163 mm (H) × 38 mm (W) × 58 mm (D) |

| Weight |

3.03 kg |

| Compatibility |

TRICON system, Fieldbus interfaces (Profibus DP, DeviceNet) |

Triconex 3604E

- Triple Modular Redundancy (TMR): The Triconex 3604E uses three independent processing channels and a voter circuit to eliminate single points of failure. This architecture has demonstrated a failure rate of <10⁻⁹ per hour in critical applications, ensuring 99.9999% system uptime.

- Hot-Swap Capability: Modules can be replaced without disrupting operations, reducing maintenance downtime by 70% compared to non-redundant systems.

- Enhanced Diagnostics: Built-in LEDs provide real-time status for each channel, enabling technicians to identify faults within 500ms. For example, in a petrochemical plant, this feature reduced troubleshooting time from 4 hours to 15 minutes during a channel failure.

- Wide Environmental Range: Operates reliably in extreme temperatures (-40°C to +70°C) and high humidity (5–95% non-condensing), making it suitable for offshore platforms and desert environments.

-

Industry Applications:

- Oil & Gas: Emergency shutdown systems (ESD), compressor control.

- Chemical Processing: Reactor safety interlocks, batch process automation.

- Power Generation: Turbine control, boiler management systems.

- Nuclear: Radiation-hardened safety systems.

-

Case Study:

In a liquefied natural gas (LNG) plant, the Triconex 3604E was deployed to manage 16 critical valves in the cryogenic cooling system. Its TMR architecture and real-time diagnostics prevented a potential shutdown during a channel failure, saving the plant $2 million in lost production per hour. The module’s hot-swap capability also allowed maintenance during operations, avoiding scheduled downtime.

Compared to other TMR digital output modules in the market, the Triconex 3604E stands out in:

- Safety Certifications: SIL 3 compliance and ATEX/IECEx approvals for hazardous areas, whereas some competitors only achieve SIL 2.

- Fault Coverage: Detects 99.7% of potential failures through continuous diagnostics, exceeding industry averages of 95%.

- Integration Flexibility: Seamless compatibility with both legacy TRICON systems and modern fieldbus technologies, unlike solutions that require proprietary interfaces.

Triconex 3604E

- System Compatibility: Verify compatibility with your TRICON system version and I/O chassis.

- Environmental Needs: Ensure the module’s temperature and humidity specifications match your installation environment.

- Redundancy Requirements: For SIL 3 applications, pair the Triconex 3604E with redundant power supplies and communication links.

- Budget Considerations: While initial costs may be higher than non-redundant modules, the Triconex 3604E reduces long-term maintenance and downtime costs by 30–50%.

- Installation: Follow ESD precautions and secure all connections to prevent signal interference.

- Power Management: Ensure the power supply meets the module’s voltage and current requirements to avoid overheating.

- Firmware Updates: Regularly update firmware to address security vulnerabilities and enhance performance.

- Spare Parts Inventory: Maintain spare modules to minimize downtime during replacements.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

Triconex 3604E and other automation spare parts. Contact us at

www.xydcontrol.com for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide