Description

1. Product Description

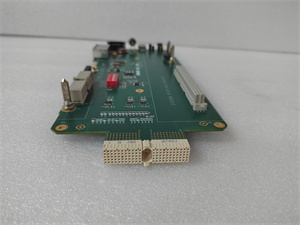

The TRICONEX 3381 is a high-reliability pulse input module engineered for safety-critical industrial automation systems, specializing in precise speed and frequency monitoring of rotating machinery. As a core component of TRICONEX’s Triple Modular Redundancy (TMR) architecture, the TRICONEX 3381 processes pulse signals through three independent channels, ensuring data integrity and uninterrupted operation in environments where accurate measurements are non-negotiable.

The primary function of the TRICONEX 3381 is to convert voltage transitions from speed sensors—such as magnetic, active, or open collector types—into high-precision frequency data (RPM) for real-time monitoring and control. It supports 6 isolated input channels with differential or single-ended configurations, accommodating input voltages up to ±33V DC and frequencies up to 32 kHz. This makes it ideal for applications requiring precise speed measurement in rotating equipment like turbines, compressors, and pumps across industries such as oil & gas, power generation, and chemical processing.

Key advantages of the TRICONEX 3381 include its SIL-3 certification (IEC 61508), which ensures compliance with the highest safety integrity levels, and its loop-back diagnostics, which continuously verify signal integrity to detect faults in sensors or wiring. The module’s hot-swappable design allows for maintenance without system shutdown, while its rugged construction resists extreme temperatures (-40°C to +70°C) and electromagnetic interference (EMI), ensuring reliable performance in harsh industrial settings.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Pulse Input Module for TMR systems |

| Power Supply | 24V DC (±15%), isolated |

| Input Channels | 6 isolated channels (differential or single-ended) |

| Input Voltage Range | ±33V DC (minimum: 500 mV p-p for differential inputs) |

| Frequency Range | 0 to 32 kHz (resolution: 24 bits, accuracy: ±0.01% at full scale) |

| Redundancy | Triple Modular Redundancy (TMR) with 2-out-of-3 voting |

| Operating Temperature | -40°C to +70°C (storage: -50°C to +85°C) |

| Humidity | 5%–95% non-condensing |

| SIL Certification | SIL-3 (IEC 61508) |

| Compatibility | TRICONEX Triplex control systems, Tricon Vx platforms |

| Signal Types | Voltage pulses, frequency signals, speed sensor outputs |

TRICONEX 3381

3. Advantages and Characteristics

- Triple Modular Redundancy (TMR): The TRICONEX 3381 uses TMR technology to process signals through three independent channels, achieving a mean time between failures (MTBF) exceeding 250,000 hours. This redundancy ensures continuous operation even if one channel fails, reducing the risk of unplanned downtime by up to 90% compared to non-redundant modules.

- High-Precision Measurement: With a 24-bit resolution and ±0.01% accuracy at 32 kHz, the module provides precise speed monitoring for high-speed machinery, critical for applications like turbine overspeed protection where even minor errors can lead to safety risks.

- Loop-Back Diagnostics: Real-time feedback loops monitor sensor health and wiring integrity, detecting faults such as loose connections or signal degradation. This feature reduces troubleshooting time by 50%, enabling proactive maintenance and minimizing repair delays.

- Rugged Environmental Performance: Designed to withstand extreme temperatures, high vibration, and EMI, the TRICONEX 3381 operates reliably in harsh environments like offshore platforms or chemical plants, where standard modules might fail.

- Hot-Swap Capability: Faulty modules can be replaced without powering down the system, allowing maintenance during operation and reducing downtime by up to 60% in critical setups.

4. Application Areas and Application Cases

-

Industry Applications:

- Oil & Gas: Monitors compressor and turbine speeds in offshore platforms, ensuring safe operation and preventing overspeed-related failures in wellhead systems.

- Power Generation: Supports turbine overspeed protection, generator synchronization, and feedwater pump control in thermal and nuclear power plants.

- Chemical Processing: Measures agitator and conveyor belt speeds in reactors and production lines, enabling precise process control and safety interlocks.

-

Case Study:

A major LNG processing plant in Australia deployed the TRICONEX 3381 to monitor the speed of a high-speed centrifugal compressor in its liquefaction unit. The module’s TMR architecture and loop-back diagnostics detected a gradual decline in sensor signal quality due to a corroded connection. Before the fault impacted operations, the system automatically switched to a redundant channel, allowing maintenance teams to replace the sensor during a scheduled shutdown. This proactive approach prevented an unplanned outage that could have disrupted LNG production for 8 hours, saving an estimated $3 million in lost output.

5. Competitive Comparison

Compared to similar pulse input modules, the TRICONEX 3381 stands out for its combination of SIL-3 certification, TMR redundancy, and high-frequency measurement capabilities. While some alternatives offer basic pulse counting, few match its ability to handle safety-critical applications with three independent channels and real-time diagnostics. Its wide input voltage range and environmental resilience also make it a more versatile choice for harsh industrial environments, outperforming modules with limited temperature tolerance or diagnostic features.

TRICONEX 3381

6. Selection Recommendations

- System Compatibility: Verify that the TRICONEX 3381 is compatible with your TRICONEX control platform (e.g., Tricon Vx, Trident) and backplane configuration to ensure seamless integration.

- Sensor Requirements: Confirm the module’s input voltage range (±33V DC) and frequency capacity (32 kHz) match your speed sensors, such as magnetic pickups or optical encoders.

- Environmental Needs: If installing in extreme conditions (e.g., offshore, high-temperature zones), ensure the module’s temperature (-40°C to +70°C) and humidity ratings align with site requirements.

- Safety Standards: For applications requiring SIL-3 compliance (e.g., safety instrumented systems), ensure the TRICONEX 3381 meets both IEC 61508 standards and project-specific safety protocols.

7. Precautions

- Installation: Power down the system and use anti-static wrist straps during installation to prevent electrostatic discharge (ESD) damage. Securely ground the module and use shielded cables to minimize EMI interference.

- Wiring Checks: Regularly inspect sensor and power connections for tightness and corrosion, especially in high-vibration environments, to maintain signal integrity.

- Firmware Updates: Use TRICONEX-approved software tools to update firmware, ensuring access to the latest diagnostic features and safety patches.

- Diagnostic Monitoring: Leverage the module’s built-in diagnostics to monitor channel health and signal quality in real time, addressing anomalies promptly to avoid cascading failures.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide the sales and technical support of TRICONEX 3381 and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide