Description

The

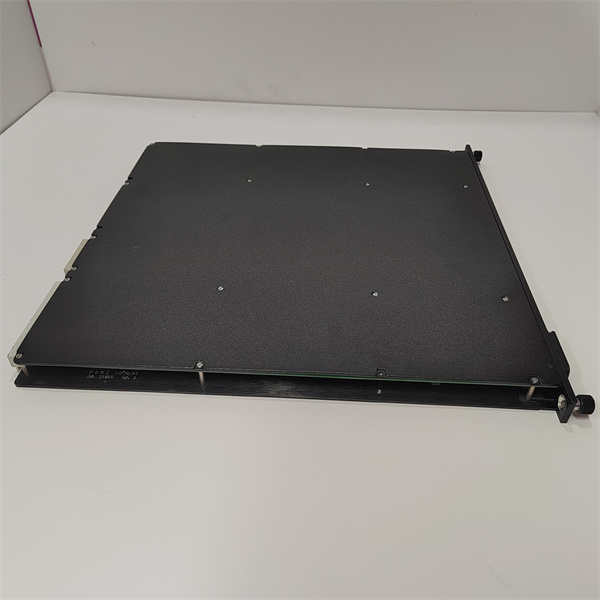

TRICONEX 3005 is a high-performance

Tricon Microprocessor Module designed as the core controller for TRICONEX Triple Modular Redundancy (TMR) systems. Engineered for safety-critical applications, the

3005 features three independent microprocessors that execute control logic in parallel, providing fault tolerance and ensuring continuous operation even in the event of a single processor failure. As a cornerstone of TRICONEX’s TMR architecture, this module delivers deterministic control, real-time diagnostics, and seamless integration with I/O modules, making it ideal for industries requiring ultra-reliable automation, such as oil & gas, power generation, and chemical processing. The

TRICONEX 3005 is built to handle complex control algorithms, safety interlocks, and high-speed data processing while adhering to rigorous safety standards like IEC 61508 (SIL 3).

| Parameter |

Specification |

| Processor Architecture |

Triple Modular Redundancy (TMR) with three independent 32-bit microprocessors |

| Memory |

256 MB RAM, 512 MB Flash (expandable for application code) |

| Communication Interfaces |

Ethernet (10/100 Mbps), RS-485, Serial (for programming and diagnostics) |

| Clock Speed |

200 MHz per processor core |

| Redundancy Support |

Built-in self-diagnosis and automatic failover between processors |

| Operating Temperature |

-40°C to +70°C |

| Safety Certifications |

IEC 61508 (SIL 3), IEC 61511 (SIS), API 615, CE, UL |

| Dimensions |

8.5” (H) x 5.2” (W) x 10.8” (D) |

| Power Supply |

24V DC (±10%) from TRICONEX power modules |

TRICONEX 3005

- Triple Modular Redundancy (TMR): The 3005’s unique TMR design ensures high availability by voting on results from three independent processors, eliminating single points of failure. This architecture achieves a hardware fault tolerance (HFT) of 1, making it suitable for SIL 3 applications.

- Real-Time Performance: With a deterministic execution cycle as low as 10 ms, the module handles time-critical control tasks, such as emergency shutdown systems (ESD) and turbine control.

- Advanced Diagnostics: Built-in self-test (BIST) functions continuously monitor processor health, memory integrity, and communication links, providing diagnostic coverage (DC) exceeding 99%. This reduces mean time to detect (MTTD) faults and enables predictive maintenance.

- Scalability: Supports up to [X] I/O modules per rack, allowing flexible system expansion for small to large-scale applications.

- Cyber-Security Features: Includes secure boot and encrypted firmware updates to protect against unauthorized access and ensure system integrity.

- Application Areas:

- Safety Instrumented Systems (SIS) in oil refineries and LNG plants.

- Power plant boiler control and turbine protection systems.

- High-reliability manufacturing lines in automotive and pharmaceutical industries.

- Application Case: A major chemical plant integrated the TRICONEX 3005 into its SIS to manage critical reactor safety interlocks. The module’s TMR architecture prevented production downtime during a single processor fault, as the system automatically switched to the redundant processors without interrupting operations. Additionally, its real-time diagnostics identified a potential memory issue before it escalated, allowing scheduled maintenance and avoiding an estimated $1.2 million in unplanned downtime costs.

Compared to single-processor or dual-redundant controllers, the TRICONEX 3005 offers superior fault tolerance and safety integrity due to its TMR architecture. Unlike non-SIL-certified alternatives, it guarantees compliance with the highest functional safety standards, making it a preferred choice for applications where system failure risks severe safety or environmental consequences. Its seamless integration with TRICONEX’s ecosystem of I/O modules and software tools also provides a more cohesive and optimized solution compared to mixed-vendor systems.

TRICONEX 3005

- Safety Requirements: Confirm that the module’s SIL 3 certification aligns with your application’s safety integrity level (SIL) and risk assessment.

- Processing Needs: Evaluate the complexity of control logic and required cycle times. The 3005 is suitable for medium to high complexity applications; consider higher-end TRICONEX models for ultra-complex systems.

- System Compatibility: Ensure compatibility with existing TRICONEX racks, power supplies, and I/O modules. Verify communication protocols (e.g., Modbus, OPC UA) for integration with supervisory control and data acquisition (SCADA) systems.

- Future-Proofing: Account for potential system upgrades, such as adding remote I/O or expanding control loops, by selecting a module with adequate memory and scalability.

- Installation:

- Install the module in a grounded TRICONEX rack with proper electrostatic discharge (ESD) protection.

- Avoid exposing the module to direct sunlight, moisture, or extreme vibrations; use anti-vibration mounts if necessary.

- Firmware Management:

- Use only TRICONEX-approved firmware versions and follow the manufacturer’s update procedures to prevent compatibility issues.

- Back up configuration files before firmware updates to restore functionality in case of interruptions.

- Maintenance:

- Regularly review diagnostic reports via the TRICONEX software to monitor processor health and identify early signs of degradation.

- Schedule annual inspections to clean dust from the module’s heatsinks and verify secure connections in the rack.

- When replacing the module, ensure all power sources are disconnected and follow hot-swap procedures if applicable (consult TRICONEX documentation for specifics).

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for

TRICONEX 3005 and other automation spare parts. Visit our website

www.xydcontrol.com or contact us for personalized solutions.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide