The

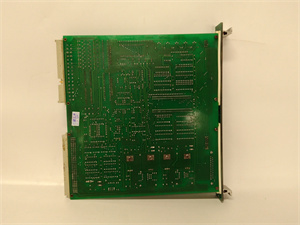

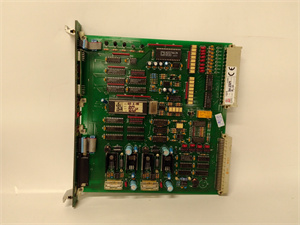

TRICONEX 2402 is a high-reliability digital input module designed for critical industrial control systems, serving as a key component of TRICONEX’s Tricon® platform. This module is engineered to acquire binary signals from field devices such as switches, sensors, and relays, converting them into digital data for processing by Tricon controllers. The

TRICONEX 2402 features a robust design with triple modular redundancy (TMR), making it ideal for safety-critical applications in industries like oil & gas, petrochemicals, and power generation. Its ability to withstand harsh environments—including extreme temperatures, voltage surges, and electromagnetic interference—ensures continuous operation in demanding conditions. The

2402 integrates seamlessly with TriStation™ software for configuration and diagnostics, providing real-time status updates to maintain system integrity and compliance with safety standards like IEC 61508/61511.

| Parameter |

Details |

| Signal Types |

24 VDC digital input (sink/source compatible) |

| Channels |

16 isolated channels (non-isolated between channels) |

| Input Voltage Range |

16–30 VDC (with overload protection) |

| Noise Immunity |

>2000 V/m electromagnetic compatibility (EMC) |

| Compatibility |

Tricon V9000, V8000, and Legacy series controllers |

| Power Supply |

24 VDC (via backplane, redundant power supported) |

| Operating Temperature |

-40°C to +70°C |

| Safety Integrity Level |

SIL 3 (certified for use in Safety Instrumented Systems) |

| Fault Detection |

Open circuit, short circuit, and voltage anomaly detection |

TRICONEX 2402

- TMR Architecture: The TRICONEX 2402’s triple redundancy ensures fault tolerance by voting on signals from three independent channels, reducing single-point failures by over 99%. This design is critical for applications requiring high availability, such as emergency shutdown systems.

- High-Speed Acquisition: With a signal update rate of <10 ms, the module captures transient events accurately, making it suitable for fast-responding control loops. For example, it can detect a safety switch activation in milliseconds, triggering immediate system responses.

- Integrated Diagnostics: Built-in self-test (BIST) functionality continuously monitors channel health, with diagnostic coverage exceeding 95%. Faults are reported to the controller in real time, enabling proactive maintenance and minimizing downtime.

- Applicable Industries: Widely used in industrial automation, safety instrumented systems (SIS), and machine control across sectors like manufacturing, water treatment, and aerospace.

- Application Case: A chemical plant deployed the TRICONEX 2402 to monitor emergency stop buttons and valve position switches in its reactor units. During a routine maintenance test, the module detected a faulty input channel due to a loose connection. The TMR architecture automatically ignored the faulty channel, allowing the system to continue operating without interruption. This prevented a potential shutdown and saved over $100,000 in production losses while ensuring compliance with safety regulations.

Compared to standard digital input modules, the 2402 offers superior safety certification (SIL 3) and a broader operating temperature range, making it suitable for extreme environments without auxiliary cooling. Its TMR design eliminates the need for external redundancy modules, reducing hardware costs by up to 25% and simplifying system architecture. Unlike some alternatives, the 2402 provides deterministic signal processing, ensuring synchronized data acquisition across all channels in high-speed control systems.

TRICONEX 2402

- Signal Requirements: Confirm the input voltage range and signal type (sink/source) of your field devices to ensure compatibility with the 2402’s specifications.

- Redundancy Needs: For SIL 3 systems, pair the module with a redundant Tricon controller and backplane to achieve full system redundancy.

- Environmental Factors: In high-EMI or corrosive environments, use shielded cables and proper grounding to maintain signal integrity and module longevity.

- Installation: Handle the module with anti-ESD equipment and follow the Tricon hardware manual for correct insertion into the backplane.

- Wiring: Ensure proper polarization of DC inputs to avoid damage. Use twisted-pair cables for long runs to minimize noise interference.

- Maintenance: Regularly inspect connections for wear and tear, and perform functional tests (recommended quarterly) to verify diagnostic accuracy. Avoid hot-swapping the module unless the system is in a safe state.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide sales and technical support for [TRICONEX 2402] and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us for dedicated service.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide