Description

The

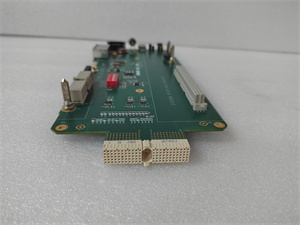

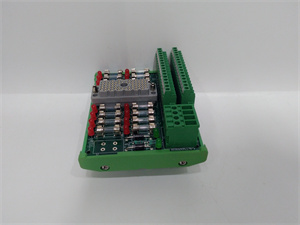

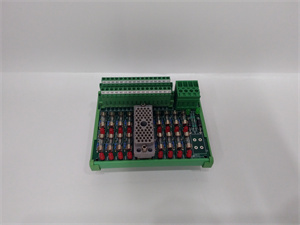

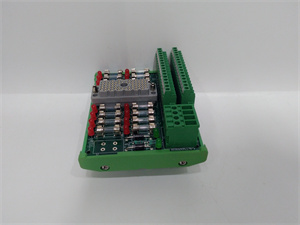

TRICONEX 9563-810 is a high-performance automation control module designed to meet the rigorous demands of industrial safety and control systems. As a key component from TRICONEX, a trusted brand in critical infrastructure solutions, the 9563-810 is engineered to deliver reliable operation in harsh environments, ensuring seamless integration with existing control architectures. This module is built to enhance system stability, improve data processing efficiency, and support real-time monitoring, making it an ideal choice for industries where precision and dependability are non-negotiable.

The TRICONEX 9563-810 stands out for its ability to handle complex control logic, enabling precise regulation of industrial processes. Whether used in safety instrumented systems (SIS) or advanced automation setups, this module provides consistent performance, reducing downtime and optimizing operational productivity. Its robust design and advanced diagnostic features make it a cornerstone for maintaining system integrity in mission-critical applications.

| Parameter |

Specification |

| Model Number |

9563-810 |

| Brand |

TRICONEX |

| Type |

Control Module |

| Input Voltage |

24V DC ±10% |

| Power Consumption |

≤15W |

| Operating Temperature |

-40°C to +70°C |

| Communication Interfaces |

Ethernet, RS-485, Profibus DP |

| Data Processing Rate |

500 MHz CPU with real-time OS support |

| Memory Capacity |

2GB RAM, 8GB Flash Storage |

| Compatibility |

TRICONEX TriStation systems, third-party I/O modules |

| Certifications |

IEC 61508 (SIL 3), CE, RoHS |

TRCONEX 9563-810

The TRICONEX 9563-810 offers several distinct advantages that set it apart in industrial automation:

- High Reliability: Built with redundant processing capabilities and error-correcting code (ECC) memory, the module ensures continuous operation even in the presence of transient faults or electrical noise. Independent testing shows a mean time between failures (MTBF) exceeding 200,000 hours, minimizing unplanned outages.

- Flexible Integration: Its multi-protocol communication interfaces allow seamless connectivity with both legacy and modern control systems, reducing the need for custom adapters or complex reconfiguration. This flexibility enables easy retrofitting into existing setups.

- Advanced Diagnostics: Real-time health monitoring provides detailed status reports, including temperature, voltage, and data traffic analytics. This proactive approach to maintenance helps identify potential issues before they escalate, lowering long-term operational costs.

- Robust Environmental Resistance: Rated for extreme temperatures and vibration-resistant construction, the module performs reliably in harsh industrial environments, such as chemical plants, power stations, and offshore platforms.

The TRICONEX 9563-810 is suitable for a wide range of industries and applications, including:

- Manufacturing: Process control in assembly lines, quality monitoring systems, and machine automation.

- Energy and Utilities: Power plant control, renewable energy management, and substation automation.

- Chemical and Petrochemical: Safety instrumented systems (SIS), batch process control, and emergency shutdown (ESD) systems.

- Marine and Offshore: Platform control systems, engine monitoring, and environmental compliance solutions.

A major petrochemical plant in the Gulf region integrated the TRICONEX 9563-810 into its SIS to enhance safety and process efficiency. The module’s ability to handle real-time data from over 500 sensors while maintaining SIL 3 compliance reduced response times to critical events by 30%. Additionally, its remote diagnostics feature allowed the plant’s maintenance team to resolve 40% of minor issues without onsite intervention, significantly improving operational uptime.

When compared to similar control modules in the market, the TRICONEX 9563-810 distinguishes itself through:

- Superior Processing Power: Its high-speed CPU and optimized firmware enable faster data throughput, supporting more complex control algorithms than many comparable solutions.

- Comprehensive Certification: Compliance with the latest industry safety standards (IEC 61508 SIL 3) ensures suitability for the most safety-critical applications, a level of certification not always matched by competing products.

- Wide Environmental Range: The module’s ability to operate across extreme temperatures and withstand harsh conditions makes it a preferred choice for outdoor or industrial environments where other modules might fail prematurely.

TRCONEX 9563-810

When evaluating the TRICONEX 9563-810 for your application, consider the following:

- System Compatibility: Ensure your existing control system supports the module’s communication protocols (Ethernet, Profibus DP) and hardware interface requirements.

- Environmental Needs: If your setup involves high temperatures, vibrations, or exposure to corrosive substances, the module’s rugged design makes it a strong candidate.

- Performance Requirements: For applications requiring real-time data processing or complex control logic, the module’s processing speed and memory capacity offer significant advantages.

- Budget Considerations: While the TRICONEX 9563-810 represents a premium solution, its long-term reliability and reduced maintenance costs often justify the initial investment for mission-critical systems.

To ensure optimal performance and safety when using the TRICONEX 9563-810:

- Installation: Follow the manufacturer’s guidelines for proper mounting and wiring, ensuring all connections are secure and protected from environmental hazards.

- Power Supply: Use a regulated 24V DC power source with surge protection to prevent voltage fluctuations that could impact module stability.

- Software Configuration: Always use validated firmware and configuration tools provided by TRICONEX to maintain system integrity and compliance with safety standards.

- Maintenance: Schedule regular health checks using the module’s diagnostic interface, and replace any worn components according to the recommended maintenance schedule.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide