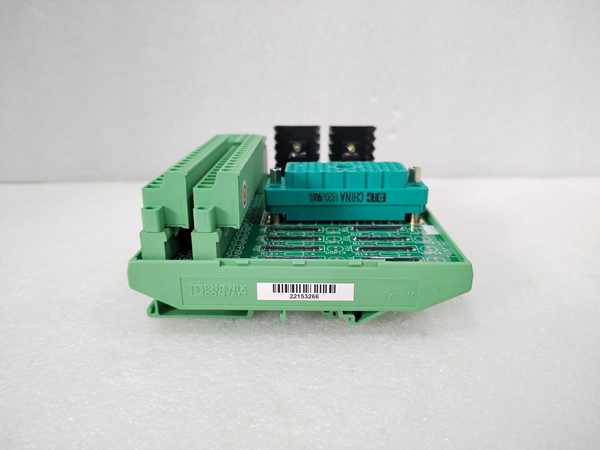

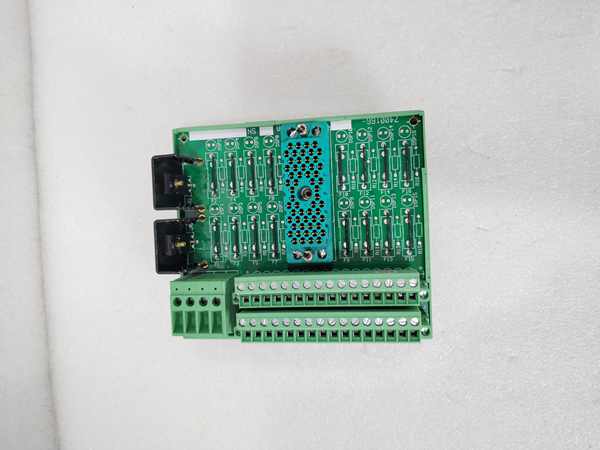

Description

1. Product Description

The TRICONEX 9662-610 is a state-of-the-art fault-tolerant controller that is built upon the robust Triple Modular Redundancy (TMR) architecture. As a crucial component in industrial automation systems, the TRICONEX 9662-610 offers unparalleled reliability and performance, making it an ideal choice for safety-critical and high-demand industrial applications.

The core function of the TRICONEX 9662-610 is to provide precise control and monitoring capabilities while ensuring system integrity. Its TMR architecture consists of three identical sub-circuits that operate independently and use a two-out-of-three voting mechanism to make decisions. This setup effectively eliminates single-point failures, delivering high-integrity, error-free, and uninterrupted process operation. From an operational perspective, it simplifies the user experience as the triplicated TMR system functions as a single, unified control system, streamlining the application software setup.

In addition to its control functions, the TRICONEX 9662-610 also serves as an interface module, enabling seamless communication and data exchange between different devices and system components. It supports a wide range of communication protocols and can integrate with various industrial devices, such as sensors, actuators, and other control systems.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Fault-Tolerant Controller |

| Input Range | 0 – 20 mA or 4 – 20 mA |

| A/D Converter Resolution | 16-bit |

| Normal-Mode Rejection Ratio | 18 dB at 50 Hz, 20 dB at 60 Hz |

| Input Filter Response | Single-pole, – 3 dB at 6 Hz |

| Crosstalk | 60 dB from DC to 60 Hz (channel-to-channel) |

| Input Impedance | 250 Ω |

| Input Voltage Range | 33 VDC to – 1 VDC |

| Input Scan Rate | 10 ms |

| Hardware Accuracy | 0.1% of full-scale at 23.5 ± 2°C, 0.175% of full-scale at 0 to 70°C, 0.25% of full-scale at – 40 to 70°C |

| Short-Circuit Current Limit | 25 mA |

| Supported I/O Modules | Up to 118 (analog and digital) |

| Communication Compatibility | Modbus hosts and slaves, Foxboro and Honeywell DCS systems |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -50°C to +85°C |

| Humidity Resistance | 5% – 95% non-condensing |

TRICONEX 9662-610

3. Advantages and Characteristics

- High Reliability: Thanks to its TMR architecture, the TRICONEX 9662-610 can continue to operate even if one of the sub-circuits fails. This significantly reduces the risk of system downtime, with a mean time between failures (MTBF) that is much higher compared to non-redundant systems. In a large petrochemical plant, for example, the controller’s TMR design ensured uninterrupted operation during a power surge that damaged one of its internal components, preventing a costly shutdown of the production line.

- Self-Diagnostic Capability: The controller is equipped with extensive diagnostic techniques that are both inherent and transparent. Built-in diagnostic indicator LEDs provide real-time information about the module’s status, allowing maintenance personnel to quickly identify and troubleshoot faults. In a power generation facility, the self-diagnostic feature detected a minor issue with an input channel, enabling the maintenance team to address it before it could cause any significant problems, thus saving time and reducing maintenance costs.

- Compatibility and Scalability: With support for up to 118 I/O modules and the ability to interface with various communication protocols and other control systems like Modbus and DCS systems from different manufacturers, the TRICONEX 9662-610 offers great flexibility in system integration and expansion. A manufacturing plant was able to easily integrate the controller into its existing production line and add new sensors and actuators as needed, without having to completely overhaul the control system.

- Easy Maintenance: The TRICONEX 9662-610 allows for online installation and repair at the module level without disturbing the field wiring. This means that routine maintenance can be carried out while the system is still in operation, minimizing downtime and ensuring continuous process control. In a food processing factory, maintenance technicians were able to replace a faulty module during a production shift without interrupting the production process, ensuring that the factory met its production targets.

4. Application Areas and Application Cases

-

Industry Applications:

- Chemical Industry: Used for controlling chemical reactions, monitoring process variables such as temperature, pressure, and flow rate, and ensuring the safety of chemical production processes. For example, in a chemical plant, it can control the opening and closing of valves to regulate the flow of chemicals and prevent dangerous situations.

- Oil and Gas: Employed in offshore platforms and onshore refineries for wellhead control, pipeline monitoring, and safety shutdown systems. It can accurately detect and respond to changes in the oil and gas production process, ensuring efficient and safe operations.

- Power Generation: Applied in power plants for turbine control, generator protection, and grid stability management. It can monitor and control the operation of power generation equipment to ensure a stable power supply.

- Manufacturing: Utilized in automated manufacturing lines for controlling robots, conveyor belts, and other production equipment. It helps to improve production efficiency and product quality by providing precise control and monitoring.

-

Case Study: In a large chemical plant, the TRICONEX 9662-610 was installed to manage the production process of a highly reactive chemical. The controller’s TMR architecture and self-diagnostic capabilities ensured that any potential issues were quickly detected and addressed. During a routine operation, the self-diagnostic system detected a minor fault in one of the sensor interfaces. Maintenance personnel were able to replace the faulty component online without interrupting the production process. As a result, the plant was able to maintain its production schedule and avoid costly production losses.

5. Competitive Comparison

Compared to other fault-tolerant controllers in the market, the TRICONEX 9662-610 stands out due to its advanced TMR architecture, which offers higher levels of redundancy and reliability. While some competing products may have basic redundancy features, they often lack the comprehensive diagnostic capabilities and flexibility of the TRICONEX 9662-610. Additionally, the controller’s wide compatibility with different communication protocols and other control systems makes it more versatile and easier to integrate into existing industrial setups. Its ability to support a large number of I/O modules also gives it an edge over competitors with more limited expansion capabilities.

TRICONEX 9662-610

6. Selection Recommendations

- System Compatibility: Before selecting the TRICONEX 9662-610, carefully assess the compatibility with your existing control system, including the communication protocols, I/O requirements, and software interfaces. Ensure that it can seamlessly integrate with your current infrastructure to avoid any integration issues.

- Application Requirements: Consider the specific requirements of your application, such as the number of input and output channels needed, the accuracy of measurement, and the level of control required. Make sure that the TRICONEX 9662-610 can meet these requirements to ensure optimal performance.

- Installation Environment: Take into account the installation environment, including the temperature, humidity, and potential exposure to electromagnetic interference. Ensure that the controller is rated for the environmental conditions of your installation site to ensure its reliable operation.

- Budget Considerations: While the TRICONEX 9662-610 offers high-performance and reliability, it is also important to consider your budget. Compare the cost of the controller with its features and benefits to determine if it provides good value for your investment. Consider the long-term cost savings in terms of reduced downtime and maintenance costs as well.

7. Precautions

- Installation: Follow the manufacturer’s installation instructions carefully to ensure proper installation. Use appropriate tools and techniques to avoid any damage to the controller or its components during installation. Ensure that all connections are secure and properly grounded to prevent electrical interference.

- Power Supply: Ensure that the power supply to the TRICONEX 9662-610 is stable and within the specified voltage range. Use a reliable power source and consider using a surge protector to protect the controller from power fluctuations and surges.

- Maintenance: Regularly perform maintenance tasks on the controller, such as checking the diagnostic indicators, cleaning the module, and updating the firmware as recommended by the manufacturer. Keep a record of all maintenance activities to help with troubleshooting in case of any issues.

- Safety: When working with the TRICONEX 9662-610, follow all safety regulations and procedures. Wear appropriate personal protective equipment (PPE) and ensure that the work area is safe and free from any hazards. Avoid touching the internal components of the controller without proper authorization and precautions.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide the sales and technical support of TRICONEX 9662-610 and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide