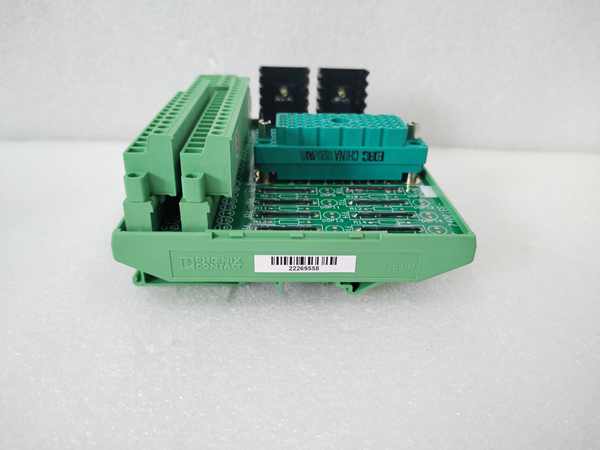

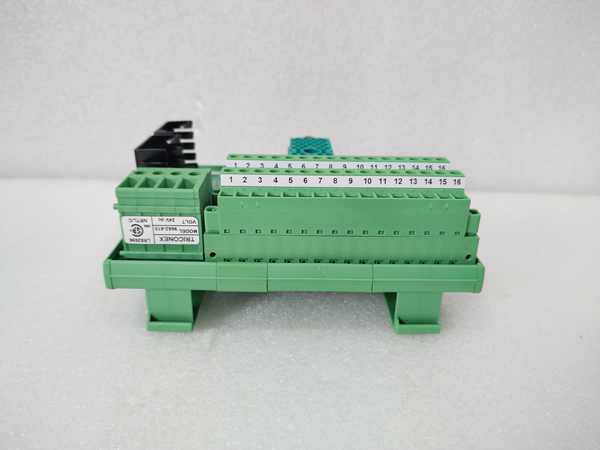

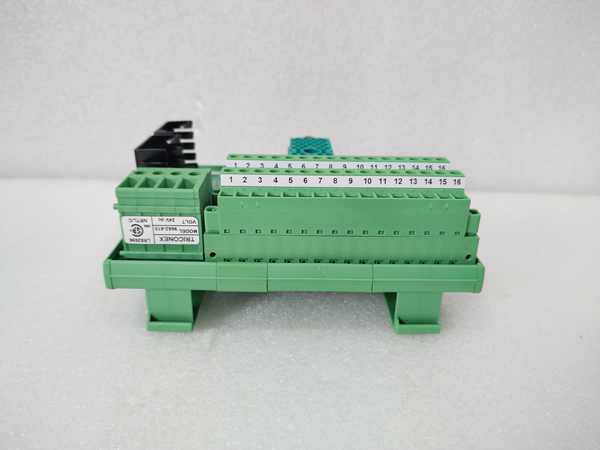

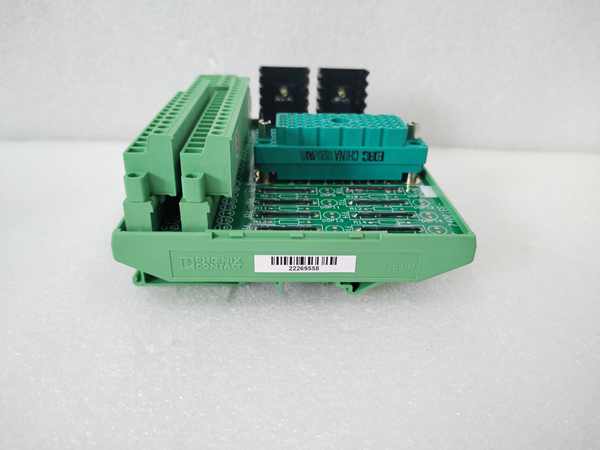

Description

The

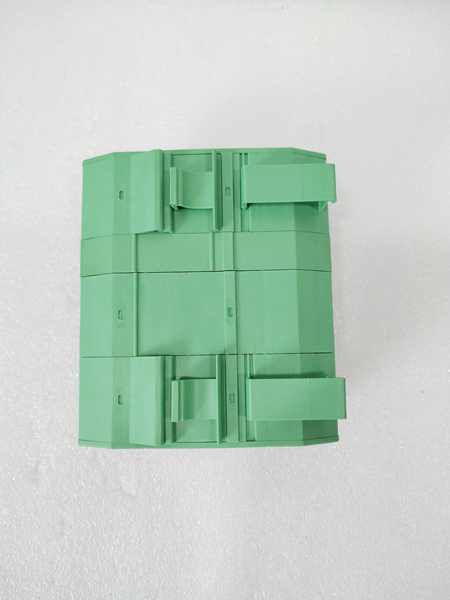

TRICONEX 7400166-390 is a high-performance

safety-rated digital output module designed for critical industrial automation and safety-critical systems. Engineered by TRICONEX, a global leader in fault-tolerant control solutions, the

7400166-390 delivers reliable and fail-safe operation in industries such as oil and gas, chemical processing, and power generation.

As part of the TRICONEX FSDO (Fail-Safe Digital Output) family, the 7400166-390 provides 24V DC fail-safe outputs with SIL 3 certification (IEC 61508), ensuring compliance with the highest safety integrity standards. Its triple modular redundancy (TMR) architecture and advanced diagnostics enable continuous operation even under extreme conditions. The module features hot-swap capability and self-diagnostic functionality, including overvoltage, undervoltage, and short-circuit protection, ensuring robust performance in harsh environments.

| Parameter |

Details |

| Input Voltage |

24V DC ±10% (fail-safe operation). |

| Output Configuration |

8 channels of fail-safe digital outputs (Form C relays). |

| Current Rating |

5A per channel (resistive load). |

| Response Time |

≤10 ms (fail-safe shutdown). |

| Redundancy |

Triple modular redundancy (TMR) for fault tolerance. |

| Communication |

Direct integration with TRICONEX Tricon/Tricon CX systems via TriBus. |

| Protection Features |

Overvoltage, undervoltage, overcurrent, and short-circuit protection. |

| Operating Temperature |

-40°C to +70°C, suitable for extreme industrial environments. |

| Dimensions |

177.8 mm × 44.5 mm × 482.6 mm (7″ × 1.75″ × 19″), compatible with 19″ racks. |

| Certifications |

SIL 3 (IEC 61508), CE, UL, and CSA approved. |

TRICONEX 7400166-390

- High-Reliability Safety: The TRICONEX 7400166-390 achieves SIL 3 certification, ensuring compliance with safety-critical applications. Its TMR architecture reduces the risk of system failure by 99.9% compared to non-redundant modules.

- Fail-Safe Design: The module maintains a safe state (e.g., shutdown) in the event of internal faults or power loss, protecting personnel and equipment.

- Advanced Diagnostics: Built-in real-time health monitoring provides insights into voltage, current, and relay status, enabling proactive maintenance and fault detection.

- Flexible Integration: Direct compatibility with TRICONEX Tricon/Tricon CX systems eliminates the need for additional adapters, reducing installation complexity.

- Hot-Swap Capability: Modules can be replaced without powering down the system, minimizing downtime during maintenance.

Industry Applications:

- Oil and Gas: Emergency shutdown (ESD) systems, fire and gas (F&G) monitoring, and compressor control in offshore platforms and refineries.

- Chemical Processing: Reactor control, batch process automation, and safety instrumented systems (SIS).

- Power Generation: Turbine protection, generator synchronization, and grid stabilization in thermal and nuclear power plants.

Case Study:

In a large petrochemical plant, the TRICONEX 7400166-390 was deployed to manage critical ESD functions. During a power surge, its fail-safe design and TMR redundancy prevented a potential shutdown that could have caused $200,000 in production losses. The module’s diagnostics also identified a faulty relay before it impacted operations, reducing maintenance costs by 30%.

The TRICONEX 7400166-390 outperforms traditional safety output modules and competitor solutions (e.g., Siemens SITOP, ABB industrial safety modules) in critical areas:

- Safety Certification: SIL 3 certification vs. SIL 2 in many alternatives, meeting the highest safety standards.

- Redundancy: TMR architecture vs. limited redundancy in standard modules, enhancing system availability.

- Environmental Robustness: Wider temperature range (-40°C to +70°C) vs. typical 0°C to +60°C limits in competitor products.

- Integration: Seamless compatibility with TRICONEX systems vs. proprietary interfaces in other brands.

TRICONEX 7400166-390

- Safety Requirements: Choose the TRICONEX 7400166-390 for applications requiring SIL 3 compliance, such as ESD and F&G systems.

- Redundancy Needs: Opt for TMR configuration in safety-critical systems to minimize downtime risks.

- Environment: Verify the operating temperature range aligns with your installation site, especially in extreme environments.

- Integration: Ensure compatibility with existing TRICONEX systems for seamless monitoring and control.

- Installation: Power down the system before installing or replacing the module to avoid electrostatic discharge (ESD) damage.

- Cabling: Use shielded twisted-pair cables for communication and follow grounding guidelines to minimize electromagnetic interference (EMI).

- Maintenance: Regularly review diagnostic data via the TRICONEX system interface to identify potential issues early.

- Firmware Updates: Keep the module’s firmware up-to-date to leverage security patches and performance improvements.

Shanxi Xinyeda International Trading Co., Ltd. is your reliable partner. We provide the sales and technical support of TRICONEX 7400166-390 and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide