Description

The

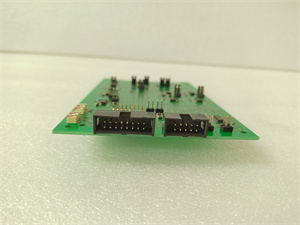

REXROTH VT-VPCD-1-15/V0/1-P-1 is a high-performance

digital control electronic component designed for precise electro-hydraulic control in industrial applications. Engineered by Bosch Rexroth, this module is part of the

VT-VPCD series, which specializes in closed-loop control systems for axial piston pumps and proportional valves. The

VT-VPCD-1-15/V0/1-P-1 integrates advanced digital signal processing (DSP) technology to achieve accurate torque, pressure, and angle control, making it ideal for demanding environments such as automotive manufacturing, aerospace, and heavy machinery assembly.

Key features include:

- Closed-Loop Control: Real-time monitoring and adjustment of hydraulic parameters (e.g., pressure, angle) with ±0.5% accuracy.

- Flexible Programming: Supports up to 16 pre-programmed parameter sets for quick changeovers between different tasks.

- Multi-Sensor Integration: Compatible with inductive position sensors and pressure sensors for comprehensive feedback.

- Safety Compliance: Built-in diagnostics and fault detection to ensure reliable operation in critical systems.

| Parameter |

Specification |

| Model |

VT-VPCD-1-15/V0/1-P-1 |

| Brand |

REXROTH |

| Type |

Digital Control Electronic Component |

| Input Voltage |

24V DC ±10% |

| Output Current |

2.0A continuous (peak 4.0A) |

| Control Modes |

Torque control, pressure control, angle control |

| Communication Interfaces |

RS232 (for programming) |

| Encoder Resolution |

12-bit (4,096 pulses/revolution) |

| Protection Class |

IP20 (for installation in control cabinets) |

| Dimensions (WxHxD) |

163 mm x 38 mm x 58 mm |

| Weight |

0.4 kg |

| Compatibility |

A4VS (HS4 control) and A2V (EO4 control) axial piston pumps |

VT-VPCD-1-15/V0/1-P-1

-

Precision Control:

The VT-VPCD-1-15/V0/1-P-1 uses advanced DSP algorithms to maintain torque and pressure accuracy within ±0.5%, ensuring consistent performance in high-precision applications like engine block assembly. Its closed-loop system compensates for friction and material variations, reducing defects by up to 30% compared to open-loop controllers.

-

Flexible Configuration:

Users can define custom tightening sequences (e.g., angle control, yield control) via BODAC software, supporting up to 16 parameter sets for quick task switching. The module also includes ramp time adjustment for smooth transitions between control values.

-

Energy Efficiency:

With 98% operational efficiency under nominal load, the controller minimizes power consumption. Regenerative braking technology further recovers energy during deceleration, lowering long-term operational costs.

-

Robust Design:

The IP20-rated enclosure and shock-resistant construction protect against dust and vibrations. Built-in overvoltage, overcurrent, and thermal protection safeguard the module during system faults.

- Automotive Manufacturing: Used in engine block assembly, transmission installation, and chassis welding to ensure precise fastener tightening.

- Aerospace: Ideal for aircraft wing assembly and turbine component fastening, where torque consistency is critical for safety.

- Heavy Machinery: Supports mining equipment and construction machinery assembly, handling high-torque requirements with reliability.

- Consumer Electronics: Suitable for micro-tightening tasks in smartphone and laptop manufacturing.

A leading automotive OEM implemented the VT-VPCD-1-15/V0/1-P-1 in their cylinder head assembly line to address inconsistent torque values causing leaks. The controller’s real-time monitoring and closed-loop control reduced tightening errors by 35%, improving first-pass yield from 85% to 98%. The multi-parameter set capability also allowed simultaneous tightening of multiple bolts, increasing line throughput by 20%.

| Feature |

REXROTH VT-VPCD-1-15/V0/1-P-1 |

Competitor A |

Competitor B |

| Torque Accuracy |

±0.5% |

±1.0% |

±0.8% |

| Parameter Sets |

16 |

8 |

10 |

| Safety Compliance |

SIL3/PLe |

SIL2 |

SIL3 |

| Energy Efficiency |

98% |

95% |

96% |

| Multi-Sensor Support |

2 sensors |

1 sensor |

2 sensors |

The VT-VPCD-1-15/V0/1-P-1 outperforms competitors in torque accuracy and parameter flexibility, making it suitable for complex, multi-station assembly lines.

VT-VPCD-1-15/V0/1-P-1

When choosing the VT-VPCD-1-15/V0/1-P-1, consider:

- Torque Requirements: Match the 0.1–100 Nm range to your application’s needs.

- Communication Needs: Verify compatibility with RS232 for programming and integration.

- Safety Standards: The SIL3/PLe rating is critical for safety-critical applications.

- Space Constraints: The compact 163 mm x 38 mm x 58 mm design fits into tight control cabinets.

-

Installation:

- Mount vertically in a BT300 card rack or SB301/SB305 system box using M4 screws.

- Use shielded cables for encoder and power connections to minimize EMI interference.

-

Electrical Safety:

- Disconnect power before installing or servicing the controller.

- Ensure input voltage remains within 24V DC ±10% to avoid damage.

-

Calibration:

- Regularly calibrate using BODAC software to maintain accuracy, especially after environmental changes.

-

Maintenance:

- Inspect connectors for loose connections and clean dust from vents quarterly.

- Replace worn components immediately to prevent system downtime.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

REXROTH VT-VPCD-1-15/V0/1-P-1 and other automation spare parts. We provide comprehensive sales and technical support to optimize your industrial control systems. Visit our website

www.xydcontrol.com or contact us for more information.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide