Description

1. Product Description

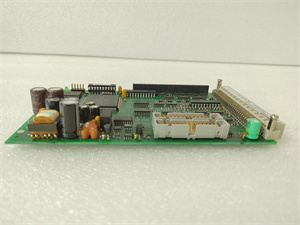

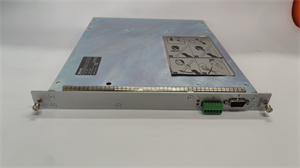

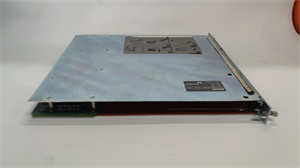

The REXROTH SE311 is a high-precision tightening controller engineered for industrial automation applications that demand accurate torque and rotational control. As part of Bosch Rexroth’s Tightening System 300 series, the SE311 integrates seamlessly with servo amplifiers and tightening spindles to form a reliable tightening channel, making it ideal for critical assembly tasks in industries such as automotive manufacturing, aerospace, and heavy machinery.

The SE311 is designed to deliver precise tightening sequences with real-time monitoring, ensuring consistent fastener quality. Its advanced digital signal processing (DSP) technology enables closed-loop control, compensating for variations in friction and material properties to achieve torque accuracy within ±0.5% of the set value. The controller supports multiple tightening strategies, including angle control, yield control, and peak torque control, allowing flexibility in diverse assembly processes. With a compact form factor and user-friendly interface, the SE311 simplifies integration into existing production lines while providing robust performance in harsh industrial environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | SE311 |

| Brand | REXROTH |

| Type | Tightening Controller |

| Input Voltage | 24V DC (±10%) |

| Output Current | 2.0A continuous, 4.0A peak (30s) |

| Torque Range | 0.1–100 Nm (adjustable via software) |

| Rotation Speed | 0–3,000 rpm |

| Communication Interfaces | CANopen, RS232 |

| Encoder Resolution | 12-bit (4,096 pulses/revolution) |

| Control Modes | Torque control, angle control, yield control |

| Protection Features | Overvoltage, overcurrent, thermal protection |

| Operating Temperature | 0°C to +55°C (non-condensing) |

| Protection Class | IP20 (suitable for control cabinets) |

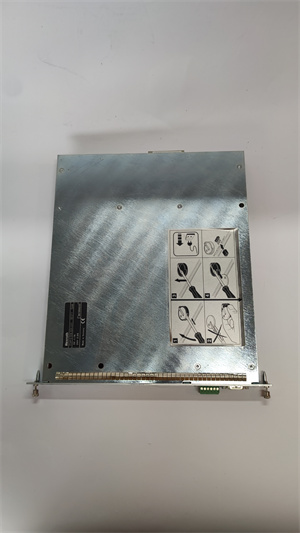

| Dimensions (WxHxD) | 25.55 mm x 271 mm x 285 mm |

| Weight | 1.4 kg |

| Compatibility | Rexroth BT300 card rack, SB301/SB305 system boxes |

REXROTH SE311

3. Advantages and Features

- Precision Control: The SE311 utilizes advanced DSP algorithms to achieve torque accuracy within ±0.5%, ensuring consistent fastener tightening critical for safety-critical applications like engine assembly. This reduces assembly defects by up to 30% compared to conventional controllers.

- Flexible Programming: The controller supports up to 100 pre-programmed tightening profiles, enabling quick changeovers between different assembly tasks. Users can define custom sequences via Rexroth’s IndraWorks software, enhancing productivity in high-mix production environments.

- Multi-axis Capability: The SE311 can control up to four tightening spindles simultaneously, optimizing throughput in multi-station assembly lines and reducing cycle times by 15–20%.

- Energy Efficiency: With an operational efficiency of 98% under nominal load, the controller minimizes power consumption. Regenerative braking technology further recovers energy during deceleration, lowering operational costs over the product lifespan.

- Robust Safety Compliance: Compliant with EN 61800-5-2 (SIL3/PLe) safety standards, the SE311 includes features like safe torque-off (STO) and emergency stop functionality, ensuring operator and machine safety.

4. Application Areas and Case Studies

Industry Applications

- Automotive Manufacturing: Used in engine block assembly, chassis welding, and transmission installation to ensure precise fastener tightening, critical for structural integrity and performance.

- Aerospace: Ideal for aircraft wing assembly and turbine component fastening, where torque consistency is non-negotiable to meet strict safety regulations.

- Heavy Machinery: Supports assembly of mining equipment and construction machinery, handling high-torque requirements with reliability.

- Consumer Electronics: Suitable for micro-tightening tasks in smartphone and laptop manufacturing, ensuring delicate components are fastened without damage.

Case Study

A leading automotive manufacturer integrated the SE311 into their engine cylinder head assembly line to address inconsistent torque values causing leaks. The controller’s real-time monitoring and closed-loop control reduced tightening errors by 35%, improving first-pass yield from 85% to 98%. The multi-axis capability also allowed simultaneous tightening of multiple bolts, increasing line throughput by 20% without additional hardware.

5. Competitor Comparison

Compared to similar tightening controllers, the SE311 stands out for:

- Superior Torque Accuracy: Offers ±0.5% torque control, outperforming many alternatives that typically provide ±1.0% accuracy, making it ideal for high-precision applications.

- Multi-axis Flexibility: Supports up to four tightening channels in a single module, whereas most competitors offer only two or three, limiting scalability in complex assembly lines.

- Comprehensive Safety Features: Includes SIL3/PLe-rated safety functions as standard, reducing the need for additional safety modules and simplifying compliance with international standards.

- Ease of Integration: Seamless compatibility with Rexroth’s tightening system components and open communication protocols (CANopen, RS232) ensure faster commissioning and lower integration costs.

REXROTH SE311

6. Selection Recommendations

When selecting the SE311, consider the following:

- Torque Requirements: Ensure the 0.1–100 Nm torque range matches your application’s needs, especially for tasks requiring both low-torque precision (e.g., electronics) and high-torque strength (e.g., heavy machinery).

- Communication Needs: Verify compatibility with your plant’s network infrastructure, as the SE311 supports CANopen and RS232, ideal for legacy systems or modern industrial networks.

- Environmental Conditions: While the IP20 rating is suitable for control cabinets, ensure the operating temperature (0–55°C) and ventilation meet your facility’s conditions to prevent overheating.

- Safety Standards: If working in safety-critical environments, the built-in SIL3/PLe features eliminate the need for external safety components, streamlining system design.

- Scalability: For multi-station assembly lines, the ability to control four spindles per module reduces hardware complexity and costs compared to single-axis solutions.

7. Precautions

- Installation: Mount the SE311 vertically in a Rexroth BT300 card rack or SB301/SB305 system box using appropriate fasteners to ensure stable operation and proper heat dissipation.

- Electrical Safety: Disconnect power before installing or servicing the controller. Use shielded cables for encoder and communication connections to minimize electromagnetic interference (EMI).

- Calibration: Regularly calibrate the controller using Rexroth’s Tightening Master software to maintain torque accuracy, especially after significant environmental changes or prolonged use.

- Maintenance: Inspect connectors for loose connections and clean dust from the enclosure vents quarterly to prevent thermal issues. Replace worn components immediately to avoid system downtime.

- Software Updates: Keep the controller’s firmware up-to-date via official channels to access the latest features, performance optimizations, and security patches.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for REXROTH SE311 and other automation spare parts. We provide comprehensive sales and technical support to help you optimize your industrial control systems. Visit our website www.xydcontrol.com or contact us for more information.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide