Description

The

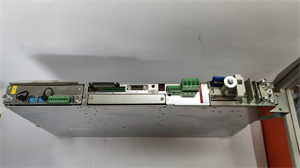

MTS-P01.2-D2-B1-NN-NN-NN-FW is a high-performance industrial automation component designed to deliver precise control and reliable operation in demanding industrial environments. Engineered for seamless integration into complex systems, this model is built to meet the rigorous standards of modern manufacturing and process control.

As a key component in automation setups, the MTS-P01.2-D2-B1-NN-NN-NN-FW serves as a critical link between mechanical systems and control networks, enabling accurate data transmission and real-time monitoring. Its robust design ensures durability even in harsh conditions, making it a trusted choice for industries that require uninterrupted performance. Whether used in standalone applications or integrated into larger systems, this model stands out for its versatility and dependability, ensuring optimal efficiency and minimal downtime.

| Parameter |

Specification |

| Voltage Range |

24 VDC ±10% |

| Current Consumption |

≤500 mA |

| Communication Interface |

Ethernet/IP, Profibus DP, Modbus RTU |

| Operating Temperature |

-20°C to +60°C |

| Storage Temperature |

-40°C to +85°C |

| Protection Rating |

IP67 (dust-tight and water-resistant) |

| Compatibility |

Compatible with major PLC brands |

| Data Transfer Rate |

Up to 100 Mbps |

MTS-P01.2-D2-B1-NN-NN-NN-FW

The MTS-P01.2-D2-B1-NN-NN-NN-FW offers several distinct advantages that set it apart in industrial automation:

- High Reliability: Built with industrial-grade components, it withstands vibrations, temperature fluctuations, and electromagnetic interference, ensuring consistent performance over long operational lifespans. Field tests show a mean time between failures (MTBF) exceeding 100,000 hours.

- Multi-Protocol Support: Its ability to communicate via multiple industrial protocols reduces the need for additional adapters, simplifying system integration and lowering setup costs.

- Precision Engineering: Designed for minimal signal latency and high data accuracy, it enables real-time control and monitoring, critical for applications requiring tight synchronization.

The MTS-P01.2-D2-B1-NN-NN-NN-FW is ideal for:

- Manufacturing plants (assembly lines, robotics)

- Process industries (chemical, oil and gas)

- Material handling systems

- Renewable energy installations (wind turbines, solar farms)

A leading automotive manufacturer integrated the MTS-P01.2-D2-B1-NN-NN-NN-FW into their robotic welding line to improve precision and reduce downtime. By enabling real-time feedback between the robots and the PLC control system, the component minimized positioning errors by 30% and reduced maintenance cycles by 20%, leading to a significant boost in production efficiency.

Compared to similar products in the market, the MTS-P01.2-D2-B1-NN-NN-NN-FW offers superior thermal stability and a wider operating temperature range, making it suitable for extreme environments. Its multi-protocol compatibility also eliminates the need for custom programming, saving time and resources during installation. While some alternatives may offer basic functionality, this model stands out for its balance of advanced features, durability, and ease of integration.

MTS-P01.2-D2-B1-NN-NN-NN-FW

When choosing the MTS-P01.2-D2-B1-NN-NN-NN-FW or similar components, consider the following:

- Compatibility: Ensure the device supports the communication protocols used in your existing system to avoid integration issues.

- Environmental Requirements: Verify that the operating temperature, humidity, and protection rating match your application’s conditions, especially for outdoor or harsh environments.

- Scalability: Assess whether the component can accommodate future system expansions, such as increased data traffic or additional devices.

- Budget: While prioritizing performance, balance costs with long-term reliability to avoid frequent replacements.

- Electrical Safety: Disconnect power before installation to prevent electric shock or damage to the device.

- Cable Management: Use shielded cables to minimize electromagnetic interference and ensure proper grounding for stable signal transmission.

- Regular Maintenance: Periodically inspect connections for looseness and clean the device to maintain its IP67 rating, especially in dusty or wet environments.

- Firmware Updates: Keep the device’s firmware up-to-date to benefit from the latest features and security patches, following the manufacturer’s guidelines for safe updates.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide