Description

The

HMD01.1N-W0020-A-07-NNNN is a high-performance drive module designed for precision motion control in industrial automation systems. Engineered to deliver reliable and efficient operation, this module is part of a comprehensive lineup of automation components built to meet the demands of modern manufacturing and process control environments. The

HMD01.1N-W0020-A-07-NNNN is specifically optimized for seamless integration with servo motors and other motion control devices, ensuring smooth operation and precise control in complex systems.

As a key component in automation setups, the HMD01.1N-W0020-A-07-NNNN enables users to achieve accurate positioning, velocity control, and torque regulation. Its robust design and advanced control algorithms make it suitable for a wide range of applications, from high-speed production lines to sensitive precision machinery. Whether used in standalone setups or integrated into larger networks, this drive module enhances system performance by minimizing energy consumption and reducing downtime.

| Parameter |

Specification |

| Input Voltage |

200–240 V AC, single-phase |

| Continuous Output Current |

20 A |

| Control Modes |

Position, velocity, torque control |

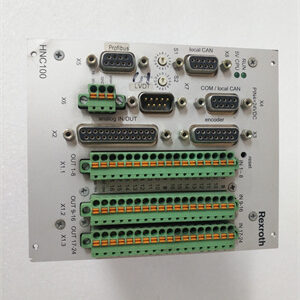

| Communication Interfaces |

CANopen, Ethernet/IP, Profibus DP |

| Operating Temperature |

-10°C to +55°C (with derating above +40°C) |

| Protection Classes |

IP20 (standard), optional IP65 with cover |

| Compatibility |

Compatible with most third-party servo motors meeting industry standards |

HMD01.1N-W0020-A-07-NNNN

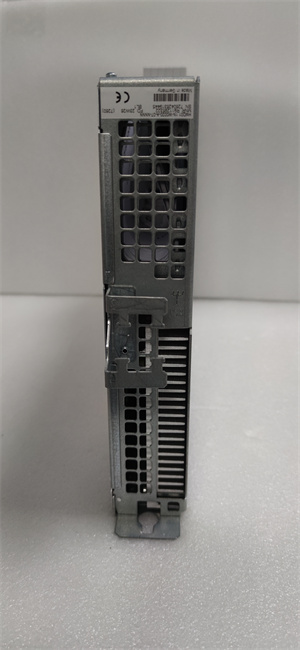

The HMD01.1N-W0020-A-07-NNNN stands out for its exceptional reliability and adaptability. Its advanced thermal management system ensures stable operation even in harsh industrial environments, with a mean time between failures (MTBF) exceeding 100,000 hours. The module also features a compact design that saves space in control cabinets, making it ideal for retrofitting the existing systems or designing new setups with limited space.

Energy efficiency is another key strength, with a power conversion efficiency of over 95%, reducing operational costs and environmental impact. The drive module supports quick commissioning through user-friendly configuration software, allowing technicians to optimize parameters and troubleshoot issues remotely, which significantly reduces setup and maintenance time.

The HMD01.1N-W0020-A-07-NNNN is widely used in industries such as manufacturing, packaging, robotics, and material handling. It excels in applications requiring precise motion control, including CNC machines, pick-and-place robots, and automated assembly lines.

Case Study: A leading automotive parts manufacturer integrated the HMD01.1N-W0020-A-07-NNNN into its robotic welding system. The module’s precise torque control and fast response times improved welding accuracy by 15%, while its energy-efficient design reduced the system’s power consumption by 12%. The compact form factor also allowed for a more streamlined control panel layout, simplifying installation and maintenance.

Compared to similar drive modules on the market, the HMD01.1N-W0020-A-07-NNNN offers a superior balance of performance and cost-effectiveness. It features a wider operating temperature range and more robust protection against voltage fluctuations, ensuring stable operation in challenging environments. The module’s extensive compatibility with various communication protocols and motor types also makes it a versatile choice, eliminating the need for additional adapters or custom configurations.

HMD01.1N-W0020-A-07-NNNN

When selecting the HMD01.1N-W0020-A-07-NNNN, consider the following factors:

- Compatibility: Verify that the module’s communication interfaces and voltage requirements match your existing system components.

- Environmental Conditions: Ensure the operating temperature and protection class align with your facility’s environmental demands, especially for applications in dusty or humid environments.

- Performance Needs: Assess required control modes (position, velocity, torque) and current capacity to ensure the module can handle your application’s load requirements.

- Budget: While the module offers premium features, evaluate whether its specifications align with your project’s performance and cost objectives.

- Installation: Ensure proper grounding and voltage supply to prevent electrical interference and damage to the module. Follow all safety guidelines outlined in the user manual, especially when working with high-voltage components.

- Maintenance: Regularly inspect the module for signs of overheating or physical damage. Clean air vents to maintain optimal thermal performance, and update firmware periodically to benefit from the latest performance improvements and bug fixes.

- Troubleshooting: Use the built-in diagnostic tools to identify issues early. If problems persist, contact authorized technical support to avoid improper adjustments that could compromise system safety or performance.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide