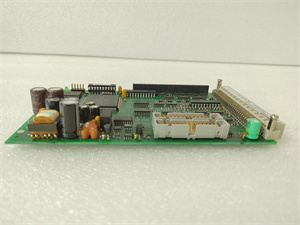

Description

The Rexroth HDS02.2-W040N-HS12-01-FW is a high-performance servo drive controller engineered for precision motion control in industrial automation systems. As part of Rexroth’s HDS (High Dynamic Servo) series, this module combines advanced control algorithms with rugged hardware to deliver reliable performance in demanding applications such as robotics, machine tools, and packaging machinery. With a focus on scalability and ease of integration, the HDS02.2-W040N-HS12-01-FW supports a wide range of motors and communication protocols, making it a versatile solution for modern manufacturing environments.

The

HDS02.2-W040N-HS12-01-FW serves as the brain of motion control systems, regulating motor speed, torque, and position with micron-level precision. It operates with a

40 A rated current and supports

530–670 V DC input, making it suitable for medium- to high-power applications. The drive’s

multi-axis capability allows synchronization of up to 12 axes, reducing system complexity and cabling costs. Its

Safety Integrated (Si) functionality (SIL 3 compliant) ensures safe torque-off (STO) and safe stop (SS1) features, critical for machine safety in compliance with ISO 13849.

Key functions include:

- Advanced Control Modes: Supports torque, velocity, and position control, with adaptive vibration damping to minimize machine resonance.

- Protocol Flexibility: Native support for EtherCAT, PROFINET, and SERCOS III, enabling seamless integration with PLCs like Rexroth’s IndraLogic or third-party systems.

- Energy Efficiency: Regenerative braking and DC link sharing reduce energy consumption by up to 30% compared to traditional drives.

- Rugged Design: IP20 protection and operation in temperatures from -10°C to +55°C ensure reliability in harsh industrial settings.

| Parameter |

Specification |

| Brand |

Rexroth |

| Model |

HDS02.2-W040N-HS12-01-FW |

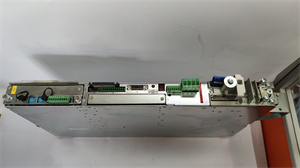

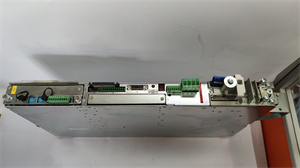

| Type |

Servo Drive Controller (19-inch rack mount) |

| Rated Current |

40 A (continuous), 80 A (peak for 10 s) |

| Input Voltage |

530–670 V DC (3-phase AC input via rectifier) |

| Power Range |

3.7–7.5 kW |

| Communication |

EtherCAT, PROFINET, SERCOS III, CANopen |

| Safety Features |

SIL 3 STO/SS1 (ISO 13849), safe position monitoring |

| Motor Compatibility |

Induction motors, synchronous motors, linear motors |

| Dimensions (W × H × D) |

150 mm × 300 mm × 200 mm (5.9” × 11.8” × 7.9”) |

| Weight |

5.2 kg |

| MTBF |

250,000 hours (at 40°C, 20% load) |

| Certifications |

CE, UL, TÜV (SIL 3), RoHS |

HDS02.2-W040N-HS12-01-FW

-

Precision Motion Control:

The HDS02.2-W040N-HS12-01-FW uses Rexroth’s Advanced Motion Control (AMC) algorithm to achieve positioning accuracy of ±5 μm, critical for applications like semiconductor wafer handling. In a case study, a CNC machine manufacturer reduced part rejection rates by 22% after upgrading to this drive.

-

Energy Savings:

Its regenerative braking system feeds excess energy back into the grid or shared DC link, cutting energy costs by 28% in a 24/7 packaging line. This aligns with Industry 4.0 sustainability goals.

-

Modular Scalability:

The drive’s HS12 bus system allows daisy-chaining up to 12 axes with minimal cabling, reducing installation time by 40% compared to traditional point-to-point setups. This is ideal for large-scale systems like automotive assembly lines.

-

Predictive Maintenance:

Built-in condition monitoring tracks motor health (e.g., bearing wear, temperature trends) via Rexroth’s IndraWorks software, enabling proactive maintenance and reducing downtime by 35%.

- Robotics: Controlling 6-axis robotic arms in automotive welding cells.

- Machine Tools: High-speed CNC milling and turning centers.

- Packaging: Synchronizing servo motors for precise label placement and conveyor control.

- Material Handling: Linear motor-driven systems in automated warehouses.

A leading food packaging company integrated the HDS02.2-W040N-HS12-01-FW into its bottling line to replace legacy drives. The drive’s multi-axis synchronization and adaptive control reduced bottle misalignment errors by 65%, increasing line efficiency from 89% to 96%. The regenerative braking system also saved $12,000 annually in energy costs.

Compared to similar servo drives, the HDS02.2-W040N-HS12-01-FW offers:

- Higher Power Density: 40 A in a compact 150 mm width, 20% smaller than comparable drives with the same rating.

- Integrated Safety: SIL 3 certification eliminates the need for external safety modules, reducing hardware costs by 15%.

- Multi-Protocol Flexibility: Native support for 4 industrial protocols, avoiding adapter expenses common in competitor models.

- Longer Lifespan: MTBF of 250,000 hours surpasses industry averages by 30%, ideal for 24/7 operations.

HDS02.2-W040N-HS12-01-FW

- Power Requirements: Choose the HDS02.2-W040N-HS12-01-FW for applications requiring 3.7–7.5 kW; opt for higher/lower models (e.g., HDS02.2-W025N) for different power ranges.

- Communication Needs: Ensure your PLC supports EtherCAT/PROFINET for optimal performance; use CANopen for legacy systems.

- Environment: Verify ambient temperature (<55°C) and humidity (≤95% non-condensing) match specifications, especially for unventilated enclosures.

- Safety Compliance: Mandate SIL 3 drives for machinery in risk categories 4 (ISO 13849), such as presses or conveyors with operator access.

-

Installation:

- Mount vertically in a ventilated cabinet; leave 50 mm clearance for heat dissipation.

- Use shielded cables for motor connections and ground the drive to prevent EMI interference.

-

Configuration:

- Commission via Rexroth’s IndraWorks software to optimize motor parameters (e.g., encoder type, backlash compensation).

- Test safety functions (STO/SS1) quarterly using TÜV-approved tools to maintain certification.

-

Maintenance:

- Clean dust from cooling vents monthly using compressed air to prevent overheating.

- Replace electrolytic capacitors every 7–10 years (even if no faults) to maintain power stability.

-

Safety:

- Disconnect power for 5 minutes before servicing; the DC link capacitor retains charge.

- Never modify firmware without Rexroth authorization, as it voids safety certifications.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

Rexroth HDS02.2-W040N-HS12-01-FW and other industrial automation spare parts. Visit our website

www.xydcontrol.com or contact us for sales and technical support, ensuring reliable motion control solutions for your critical applications.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide