Description

The

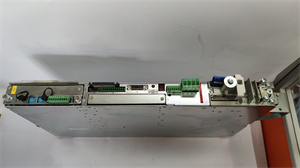

HCS02.1E-W0028-A-03-NNNN is a high-performance servo drive designed for precision motion control in industrial automation systems. Engineered to deliver reliable and efficient operation, the

HCS02.1E-W0028-A-03-NNNN is ideal for applications requiring precise speed, torque, and position control, such as robotics, conveyor systems, and machine tools. This drive combines advanced control algorithms with robust hardware to ensure stable performance even in demanding environments.

As part of a modular servo system, the HCS02.1E-W0028-A-03-NNNN simplifies integration with various motor types and control networks, reducing setup time and enhancing system flexibility. Its compact design and energy-efficient operation make it a cost-effective choice for both new installations and retrofitting existing machinery. Whether used in standalone setups or as part of a complex multi-axis system, the HCS02.1E-W0028-A-03-NNNN provides consistent performance that meets the rigorous demands of modern industrial applications.

| Parameter |

Specification |

| Model |

HCS02.1E-W0028-A-03-NNNN |

| Input Voltage |

3-phase AC 200–240V (+10%, -15%), 50/60Hz |

| Output Current (RMS) |

28A continuous, 42A peak (30s) |

| Control Modes |

Torque, speed, position (via external pulses or fieldbus) |

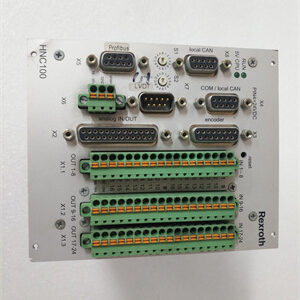

| Communication Interfaces |

CANopen, Profibus DP, EtherCAT (optional) |

| Motor Compatibility |

Synchronous servo motors, induction motors |

| Protection Features |

Overvoltage, overcurrent, overheating, short-circuit protection |

| Operating Temperature |

0–40°C (with derating up to 50°C) |

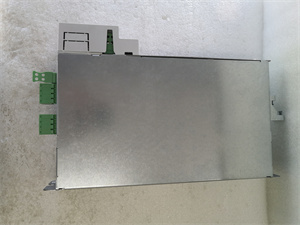

| Dimensions (WxHxD) |

120 x 220 x 170 mm |

| Weight |

3.5 kg |

HCS02.1E-W0028-A-03-NNNN

The HCS02.1E-W0028-A-03-NNNN stands out for its exceptional reliability and precision. Its advanced digital signal processing (DSP) enables rapid response times, achieving position control accuracy within ±0.1% of the rated speed. The drive also incorporates a built-in braking resistor interface, minimizing energy waste and improving system stability during dynamic stops.

Energy efficiency is a key highlight, with an operational efficiency of over 98% under nominal load, reducing power consumption and long-term operational costs. The drive’s modular design allows for easy replacement of components, decreasing downtime during maintenance. Additionally, its wide input voltage range and robust overload capacity make it suitable for unstable power environments, ensuring consistent performance without interruptions.

The HCS02.1E-W0028-A-03-NNNN is widely used in industries such as manufacturing, packaging, automotive, and material handling. It excels in applications requiring high-speed positioning, precise torque control, or seamless integration with industrial networks.

Case Study: A leading automotive assembly plant integrated the HCS02.1E-W0028-A-03-NNNN into their robotic arm system for welding operations. The drive’s fast response time and accurate torque control reduced positioning errors by 30%, improving the quality of welds and increasing production throughput by 15%. The compact size of the drive also allowed for easier installation in space-constrained robotic cells, streamlining the setup process.

Compared to similar servo drives in the market, the HCS02.1E-W0028-A-03-NNNN offers a superior balance of performance and cost. It features a higher power density, allowing more power to be packed into a smaller form factor, which is particularly advantageous for space-constrained applications. The drive’s extensive range of communication options and motor compatibility surpasses many alternatives, ensuring flexibility across diverse system setups. Its robust protection features and wide operating temperature range also make it a more reliable choice for harsh industrial environments.

HCS02.1E-W0028-A-03-NNNN

When selecting the HCS02.1E-W0028-A-03-NNNN, consider the following:

- Motor Compatibility: Ensure the drive’s output current and voltage ratings match your motor’s specifications.

- Control Network: Verify that the drive supports the communication protocol used in your system (e.g., EtherCAT, Profibus).

- Environmental Conditions: Check the operating temperature and humidity range to ensure suitability for your installation environment.

- Power Requirements: Confirm the input voltage matches your facility’s power supply to avoid compatibility issues.

- Performance Needs: Evaluate whether the drive’s control modes (torque, speed, position) align with your application’s precision and dynamic response requirements.

- Installation: Always disconnect power before installing or servicing the drive to prevent electric shock. Ensure proper grounding to reduce electromagnetic interference (EMI).

- Cooling: Maintain adequate ventilation around the drive to prevent overheating, especially in high-temperature environments.

- Parameter Setup: Calibrate motor parameters accurately during commissioning to avoid performance issues or damage to the drive or motor.

- Maintenance: Regularly inspect connectors for loose connections and clean dust or debris from the drive’s vents to ensure optimal heat dissipation.

- Safety Compliance: Integrate the drive with appropriate safety devices (e.g., emergency stops) to meet industrial safety standards.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide