Description

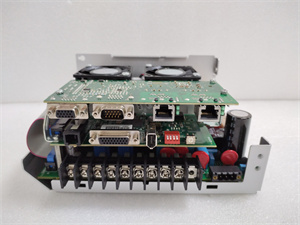

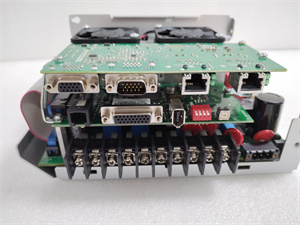

Kollmorgen S22460-SRS is a high-performance servo drive designed for industrial automation, robotics, and motion control applications. Part of Kollmorgen’s S200 series, this compact yet robust module offers advanced control algorithms, flexible configuration, and safety features to meet demanding industrial requirements.

The

Kollmorgen S22460-SRS is engineered to deliver precise position, velocity, and torque control for servo motors. Its intelligent feedback device (SFD) enables automatic parameter configuration, while high-resolution 24-bit feedback and a 3–5 kHz current loop bandwidth ensure smooth motion and rapid response times. With support for SynqNet motion networks and RJ-45 connectivity, it integrates seamlessly into modern automation systems.

| Parameter |

Specification |

| Power Supply |

240 VAC (3-phase, 47–63 Hz) |

| Current Rating |

34 ARMS peak (3-second duration) |

| Feedback Options |

Smart Feedback Device (SFD), analog torque/current control, 6 Hall sensors |

| Communication |

SynqNet option card, RJ-45 connectors |

| Safety Features |

Short-circuit protection (line-to-line/neutral/PE), over/under-voltage detection |

| Voltage Range |

20–90 VDC (compatible with AC/DC inputs) |

| Maximum Motor Cable Length |

50 m (12 AWG cable) |

| Dimensions |

150 mm × 240 mm × 350 mm |

| Weight |

1.5 kg |

| Certifications |

UL 508C, CE, EN50178, EN61800-3 |

- Compact Design: Space-efficient form factor ideal for applications with limited installation space.

- Plug-and-Play Commissioning: SFD eliminates manual tuning in most scenarios, reducing setup time.

- High Reliability: Redundant protection mechanisms (e.g., short-circuit, over-temperature) ensure operational safety.

- Scalability: Supports peak currents up to 34 ARMS for short durations, adaptable to dynamic load requirements.

- Wide Compatibility: Works with AKM servomotors and various feedback types (e.g., EnDat, Sin-Cos).

- Semiconductor Manufacturing: Controls wafer handling systems for precise positioning.

- Medical Equipment: Powers robotic surgical arms and diagnostic devices.

- Packaging Machinery: Optimizes conveyor belt speed and accuracy in high-speed production lines.

Case Study: A semiconductor plant reduced downtime by 20% using the S22460-SRS in their wafer inspection system, leveraging its real-time diagnostics and SynqNet connectivity.

The S22460-SRS outperforms comparable drives with its 34 ARMS peak current capacity (vs. 25–30 ARMS in alternatives) and SynqNet compatibility, enabling faster data transfer in multi-axis setups. Its compact size and simplified tuning also reduce integration complexity compared to bulkier models.

- Power Requirements: Match the drive’s current rating (34 ARMS peak) with motor specifications.

- Network Integration: Opt for the SynqNet option card if high-speed motion control is required.

- Environment: Ensure compliance with temperature (-15°C to +70°C) and humidity standards.

- Installation: Follow NEC 2020 guidelines for electrical wiring and grounding.

- Maintenance: Schedule annual checks for firmware updates and cable integrity.

- Power Stability: Use a surge protector to avoid voltage fluctuations damaging the drive.

山西鑫业达国际贸易有限公司 is your trusted partner for

Kollmorgen S22460-SRS and automation 备件. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide