Description

The

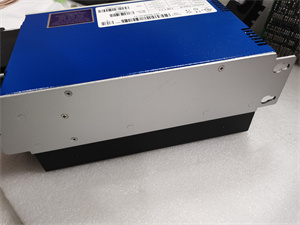

Kollmorgen CE10560 is a cutting – edge component in the realm of industrial automation, specifically designed to offer high – precision motion control. As part of Kollmorgen’s esteemed product line, the CE10560 serves as a crucial link in various automation systems. Its core function lies in providing accurate control over servo motors, ensuring smooth and precise movement. This is achieved through advanced algorithms and state – of – the – art technology embedded within the device.

The CE10560 is highly versatile and can be used in a wide range of applications, from manufacturing processes that require precise positioning of parts to high – speed packaging lines. Its advantage lies in its ability to adapt to different operating conditions and motor types, providing a reliable solution for complex automation tasks. The compact design of the CE10560 also allows for easy integration into existing systems, minimizing the need for extensive re – engineering.

| Parameter |

Specification |

| Input Voltage |

230V AC, single – phase |

| Output Power |

Up to 1.5 kW |

| Control Modes |

Position, velocity, and torque control |

| Communication Interfaces |

Ethernet, CANopen |

| Feedback Devices Supported |

Incremental encoders, absolute encoders |

| Operating Temperature |

– 20°C to + 60°C |

| Protection Class |

IP20 |

- High Precision: The CE10560 offers an extremely high level of precision in motion control. It can achieve a positioning accuracy of ±0.01 degrees, which is crucial for applications such as robotic assembly lines where precise part placement is required.

- Energy Efficiency: This device is designed to be energy – efficient, reducing power consumption by up to 25% compared to some other similar products in the market. In a large – scale manufacturing plant, this energy savings can translate into significant cost reductions over time.

- Ease of Integration: Thanks to its multiple communication interfaces and support for various feedback devices, the CE10560 can be easily integrated into existing automation systems. A case in point is a food packaging company that was able to integrate the CE10560 into their existing conveyor system without major disruptions, improving the overall efficiency of the line.

- Reliability: Built with high – quality components and a robust design, the CE10560 has a long service life. It can withstand harsh industrial environments, with a mean time between failures (MTBF) of over 50,000 hours.

- Manufacturing: In the automotive manufacturing industry, the CE10560 is used to control the movement of robotic arms during the assembly process. For example, in a car assembly plant, it ensures that the robotic arms place parts with high precision, reducing the number of defective products.

- Packaging: In packaging machinery, the CE10560 controls the speed and position of conveyor belts and labeling equipment. A beverage packaging company implemented the CE10560 in their labeling system, which led to a 15% increase in labeling accuracy and a 10% increase in production speed.

- Medical Equipment: It is also used in medical devices such as diagnostic imaging equipment. The precise motion control provided by the CE10560 ensures accurate positioning of the imaging sensors, resulting in high – quality diagnostic images.

- Performance: Compared to many competing products, the CE10560 offers a higher level of precision and faster response times. While some competitors may have similar power ratings, the CE10560 can achieve more accurate motion control, which is a significant advantage in applications where precision is critical.

- Energy Efficiency: The CE10560’s energy – saving capabilities are superior to many of its counterparts. This not only reduces operating costs but also aligns with the growing trend towards sustainable industrial practices.

- Integration Flexibility: With its wide range of communication interfaces and support for multiple feedback devices, the CE10560 is more flexible in terms of integration compared to some competing products. This allows users to easily incorporate it into their existing systems without having to make major changes.

- Compatibility: When selecting the CE10560, ensure that it is compatible with your existing servo motors and control systems. Check the motor specifications and the communication protocols supported by your system to ensure seamless integration.

- Environment: Consider the operating environment of your application. If the environment is harsh, with high levels of dust or moisture, you may need to take additional measures to protect the CE10560. In such cases, you may also want to consider models with a higher protection class.

- Budget: While the CE10560 offers excellent performance and features, it is important to consider your budget. Compare the cost – effectiveness of the CE10560 with other options in the market, taking into account factors such as energy savings and long – term reliability.

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding and wiring to prevent electrical interference and ensure the safe operation of the device.

- Maintenance: Regularly inspect the CE10560 for any signs of wear or damage. Clean the device and its components as recommended to maintain optimal performance.

- Software Updates: Keep the device’s firmware up – to – date. Software updates can improve performance, add new features, and enhance security.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner. We provide [Kollmorgen CE10560] and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you whole – heartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide