Description

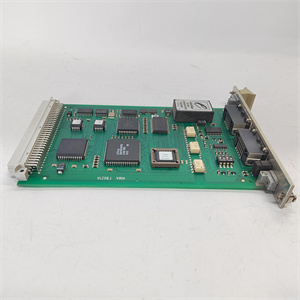

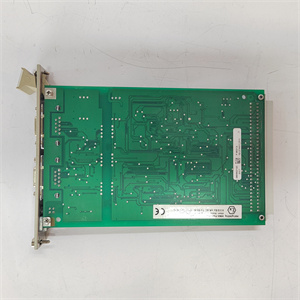

HIMA F8621A 984862160 Communication Module

The HIMA F8621A 984862160 is a high-reliability communication module engineered for safety-critical industrial automation systems, serving as a vital component of HIMA’s H41Q/H51Q safety PLC platforms. Designed to enable seamless data exchange between safety controllers, field devices, and higher-level systems, the F8621A 984862160 ensures deterministic communication and fault tolerance in environments where system failure could lead to severe consequences. Its robust design, support for multiple protocols, and compatibility with HIMA’s redundant architectures make it an ideal choice for mission-critical applications in industries such as petrochemical processing, power generation, and manufacturing.

1. Product Description

The HIMA F8621A 984862160 acts as a bridge for real-time data transmission in industrial safety systems, facilitating communication between HIMA safety controllers and external devices. It features two galvanically isolated RS-485 interfaces, supporting Modbus RTU/ASCII and PROFIBUS DP protocols to connect with sensors, actuators, SCADA systems, and HMIs. The module is optimized for redundant configurations, enabling hot-swappable dual-channel operation to ensure continuous service during maintenance or fault events.

Key functions include:

- Protocol Flexibility: Supports legacy and modern industrial protocols, eliminating the need for additional gateways and simplifying integration with diverse devices.

- Redundancy Management: Enables 2oo4D redundancy architecture, where two independent channels verify data transmission, ensuring 99.999% availability in critical systems.

- Real-Time Diagnostics: Built-in LED indicators provide instant feedback on communication status, power health, and module integrity, enabling proactive maintenance.

- Environmental Resilience: Operates reliably in extreme temperatures (-40°C to +70°C) and withstands electromagnetic interference (EMI), making it suitable for harsh industrial environments.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | HIMA |

| Model | F8621A 984862160 |

| Module Type | Safety Communication Module (19-inch rack mount) |

| Power Supply | 24 V DC ±15% |

| Power Consumption | ≤10 W (max load) |

| Communication Interfaces | 2 × RS-485 (half-duplex, galvanically isolated) |

| Supported Protocols | Modbus RTU/ASCII, PROFIBUS DP |

| Redundancy Support | Hot-swappable dual-channel (2oo4D architecture) |

| Safety Integrity Level | SIL 3 compliant (IEC 61508/61511) |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 187 mm × 128 mm × 22 mm (7.36″ × 5.04″ × 0.87″) |

| Weight | 0.16 kg |

| Certifications | CE, UL, RoHS, TÜV (SIL 3) |

F8621A 984862160

3. Advantages and Features

-

SIL 3 Safety Compliance:

The F8621A 984862160 meets the highest safety integrity level (SIL 3), ensuring compliance with international standards like IEC 61508 and IEC 61511. This makes it suitable for applications such as emergency shutdown systems (ESD) and high-integrity pressure protection systems (HIPPS), where safety failures could result in environmental hazards or operational disruptions. -

Dual-Channel Redundancy:

The module’s hot-swappable design allows for seamless replacement without system downtime, while its dual-channel architecture provides fault tolerance. In case of a channel failure, the standby channel assumes full operation, achieving a mean time between failures (MTBF) exceeding 500,000 hours—critical for 24/7 industrial processes. -

Protocol Adaptability:

Native support for Modbus RTU/ASCII and PROFIBUS DP ensures compatibility with a wide range of field devices, from legacy sensors to modern control systems. This flexibility reduces integration complexity and costs, as no additional protocol converters are required. -

Rugged Environmental Performance:

Capable of operating in temperatures ranging from -40°C to +70°C, the module withstands extreme conditions typical of industrial sites, such as offshore platforms, chemical plants, and power generation facilities. Its galvanic isolation and EMI resistance further enhance reliability in noisy electromagnetic environments.

4. Application Areas and Case Study

Application Areas:

- Petrochemical & Chemical Processing: Enables communication for ESD systems, burner management, and hazardous material handling.

- Power Generation: Supports turbine protection, boiler control, and SCADA integration in thermal and renewable energy plants.

- Manufacturing: Facilitates machine safety interlocks, robotic cell communication, and quality control systems.

- Transportation: Used in railway signaling safety systems and automated warehouse logistics.

Case Study:

A large petrochemical plant in the Gulf region integrated the HIMA F8621A 984862160 into its safety instrumented system (SIS) to connect 300+ field devices, including pressure transmitters and shutdown valves, to its H41Q safety controller. The module’s dual RS-485 interfaces and Modbus support ensured low-latency data transfer for critical safety signals, reducing response times by 25% compared to the previous non-redundant solution. The hot-swappable redundancy also minimized maintenance downtime, contributing to a 35% reduction in unplanned shutdowns over two years.

5. Competitive Comparison

Compared to similar communication modules, the HIMA F8621A 984862160 offers:

- Higher Safety Certification: SIL 3 compliance surpasses many alternatives that offer only SIL 2, making it a top choice for high-risk applications.

- Enhanced Redundancy: Built-in dual-channel redundancy eliminates the need for external hardware, reducing system complexity and potential points of failure.

- Wider Temperature Range: Operates across a broader thermal spectrum (-40°C to +70°C) than most competitors, ensuring reliability in extreme environments.

- Ecosystem Integration: Designed exclusively for HIMA’s H41Q/H51Q platforms, it provides plug-and-play compatibility with HIMA’s I/O modules and power supplies, unlike generic modules that require custom configuration.

F8621A 984862160

6. Selection Recommendations

- Safety Requirements: Choose the F8621A 984862160 if your application requires SIL 3 certification, such as processes governed by IEC 61511. For lower-risk setups, consider non-redundant alternatives.

- Protocol Needs: Ensure your field devices use Modbus RTU/ASCII or PROFIBUS DP, as the module does not natively support newer protocols like Ethernet/IP without additional adapters.

- Environmental Fit: Verify that your operational temperature and EMI exposure fall within the module’s specifications, especially for outdoor or high-vibration installations.

- Scalability: Pair with HIMA’s redundant CPU modules (e.g., F8652E) for large-scale systems requiring extensive I/O connectivity and fault tolerance.

7. Precautions

-

Installation:

- Mount the module in a grounded 19-inch rack with adequate ventilation to prevent overheating. Separate power cables from signal wires to minimize EMI interference.

- Use shielded twisted-pair cables for RS-485 connections and torque terminal screws to 1.2 N·m for secure wiring.

-

Configuration:

- Program using HIMA’s Elop II software to set protocol parameters and enable redundancy. Validate configurations with TÜV-approved tools to maintain safety compliance.

- Regularly back up project files to protect against data loss during firmware updates or module replacement.

-

Maintenance:

- Inspect LED indicators monthly: a steady green light signals normal operation, while a red light indicates a fault requiring immediate attention.

- Clean ventilation slots quarterly with compressed air to remove dust, which can degrade heat dissipation over time.

- Replace the module every 7–10 years or as per HIMA’s maintenance guidelines, even if no faults are detected, to ensure long-term reliability.

-

Safety Compliance:

- Design the system in accordance with IEC 61511, ensuring the module is part of a fully validated safety instrumented system (SIS).

- Avoid using unauthorized firmware or configuration tools, as this may compromise safety certifications.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for HIMA F8621A 984862160 and other industrial automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support, ensuring reliable communication solutions for your critical applications.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide