Description

The

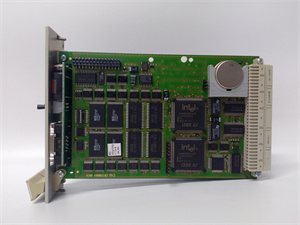

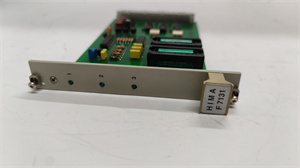

HIMA F7131 981713102 is a high-reliability safety controller module designed for critical industrial automation systems, engineered to deliver precise control and fail-safe operation in demanding environments. As a key component of HIMA’s safety-focused product portfolio, the

F7131 981713102 is built to meet the stringent requirements of safety-integrated systems, ensuring optimal performance in applications where operational safety is non-negotiable.

This module serves as a central processing unit for safety-related tasks, enabling real-time monitoring, data processing, and emergency response coordination. Its core functions include signal acquisition, logic execution, and communication with peripheral devices, all while adhering to international safety standards. The HIMA F7131 981713102 stands out for its ability to integrate seamlessly with existing automation setups, reducing downtime and enhancing system reliability. Whether deployed in complex industrial plants or simple control systems, this module provides a robust foundation for safety-critical operations.

| Parameter |

Specification |

| Power Supply |

24V DC ±15% |

| Power Consumption |

≤10W |

| Operating Temperature |

-40°C to +70°C |

| Communication Interfaces |

PROFIBUS DP, Ethernet (10/100 Mbps) |

| Input/Output Channels |

32 digital inputs, 16 digital outputs |

| Safety Integrity Level |

SIL 3 (IEC 61508), PL e (ISO 13849) |

| Memory Capacity |

512 MB flash, 256 MB RAM |

| Redundancy Support |

Hot-swappable, dual-channel redundancy |

| Compatibility |

HIMA ELOPII, HIMax safety system platforms |

HIMA F7131 981713102

The HIMA F7131 981713102 offers unparalleled advantages through its design and performance:

- Extreme Reliability: With a mean time between failures (MTBF) exceeding 500,000 hours, the module ensures continuous operation even in harsh industrial environments. Its fail-safe architecture includes self-diagnostic functions that detect faults in real time, minimizing unplanned shutdowns.

- High Safety Compliance: Certified to SIL 3 and PL e, it guarantees the highest level of safety for applications such as emergency shutdown systems, fire protection, and machinery safety.

- Flexible Integration: The module supports multiple communication protocols, allowing easy integration with both legacy and modern automation systems. Its hot-swappable design enables maintenance without system downtime, improving operational efficiency.

- Advanced Processing Power: Equipped with a high-speed processor, it handles complex logic sequences and large data volumes, ensuring rapid response to critical events (response time <50 ms).

The HIMA F7131 981713102 is ideal for industries requiring strict safety and control, including:

- Manufacturing: Machine safety systems, conveyor control, and process automation.

- Energy: Power plant safety systems, renewable energy installations, and substation automation.

- Chemical and Petrochemical: Emergency shutdown systems, pressure/vibration monitoring, and hazardous area control.

Case Study: A chemical plant in Germany integrated the F7131 981713102 into its reactor safety system. The module’s real-time fault detection and rapid emergency response capabilities helped the plant achieve a 40% reduction in safety-related downtime over two years, while maintaining full compliance with EU safety regulations.

Compared to similar safety controller modules on the market, the HIMA F7131 981713102 distinguishes itself through:

- Superior Safety Certification: Offering the highest SIL 3/PL e rating with comprehensive diagnostic coverage.

- Enhanced Redundancy Options: Supporting dual-channel redundancy for mission-critical applications, a feature not universally available in competing products.

- Wide Environmental Tolerance: Operating reliably across a broader temperature range (-40°C to +70°C) without additional cooling, making it suitable for extreme industrial settings.

HIMA F7131 981713102

When selecting the HIMA F7131 981713102, consider the following:

- System Compatibility: Ensure it aligns with your existing HIMA platform (e.g., ELOPII, HIMax) and communication protocols (PROFIBUS, Ethernet).

- Environmental Requirements: Verify that the operating temperature, humidity, and vibration resistance match your installation environment.

- Safety Needs: Confirm the SIL/PL rating meets the safety requirements of your application, especially for high-risk processes.

- Scalability: Evaluate if the module’s I/O capacity and processing power can accommodate future system expansions.

- Installation: Follow HIMA’s official guidelines for proper grounding and cable routing to prevent electromagnetic interference (EMI). Use anti-static precautions during handling.

- Maintenance: Schedule regular firmware updates and diagnostic tests to ensure optimal performance. Replace batteries (if applicable) as per the manufacturer’s recommendations.

- Safety Compliance: Always conduct a thorough risk assessment and system validation before deployment, ensuring the module is configured correctly for your safety logic requirements.

- Spare Parts: Keep a validated spare module on-site to minimize downtime in case of unexpected faults.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide