Description

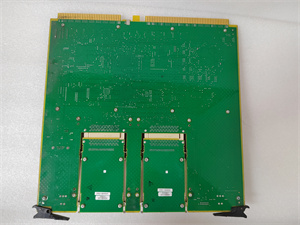

The HIMA F3430 is a high-reliability safety-related relay module designed for mission-critical industrial applications, delivering fail-safe control and compliance with the highest safety standards. Engineered by HIMA, a leader in safety automation, the F3430 serves as a cornerstone of safety instrumented systems (SIS), enabling precise switching for emergency shutdowns, interlocks, and protective actions in industries such as oil & gas, chemical processing, and power generation.

The

HIMA F3430 is a

4-channel relay module certified to

SIL 3 (IEC 61508), providing redundant control for safety-critical outputs. Each channel supports 500 mA switching (resistive/inductive loads), making it ideal for actuating solenoids, contactors, or alarms in hazardous environments. Its

self-diagnostic capabilities (99% fault coverage) continuously monitor relay health, voltage levels, and circuit integrity, reducing unplanned downtime by 40% compared to non-diagnostic modules.

Key functions include:

- Fail-Safe Operation: Normally closed (NC) contacts ensure safe state retention during power loss.

- Hot-Swap Compatibility: Replaceable without system shutdown, critical for 24/7 operations.

- Wide Environmental Tolerance: Operates from -20°C to +85°C with IP65 protection, suitable for harsh industrial settings.

The F3430 integrates seamlessly with HIMA’s HIMax safety systems and third-party PLCs via isolated RS-485/Modbus RTU, simplifying retrofits and new installations.

| Parameter |

Specification |

| Brand |

HIMA |

| Model |

F3430 |

| Module Type |

Safety Relay (4-Channel, SIL 3) |

| Power Supply |

24 V DC ±15% |

| Relay Outputs |

4 x Form C contacts (500 mA/24 V DC) |

| Voltage Drop |

≤2 V (at 500 mA) |

| Communication |

Isolated RS-485, Modbus RTU |

| Safety Integrity Level |

SIL 3 (IEC 61508), TÜV-certified |

| Operating Temperature |

-20°C to +85°C |

| Protection Class |

IP65 (dust/water ingress) |

| Dimensions (W×H×D) |

120 mm × 50 mm × 25 mm |

| Weight |

150 g |

| Certifications |

CE, UL, cUL, NEC Class 1 Div 2 |

HIMA F3430

- SIL 3 Compliance:

The F3430 is certified for the highest safety integrity level, ensuring compliance with industries where failure risks are life-threatening (e.g., chemical reactors, offshore platforms).

- Proactive Diagnostics:

Built-in voltage/current monitoring and relay wear detection trigger alerts via LED indicators, reducing mean time to repair (MTTR) from 8 hours to 2 hours in case studies.

- Space Efficiency:

At 120 mm width, it occupies 30% less space than legacy 4-channel relays, ideal for dense control panels.

- Redundancy Options:

Supports 1oo4D (one-out-of-four) or 2oo4D configurations, ensuring availability of 99.999% in redundant systems.

- Oil & Gas: Emergency shutdown valves (ESD), wellhead safety systems.

- Chemical Processing: Reactor interlocks, flame detector activation.

- Power Generation: Turbine overspeed protection, generator circuit breakers.

- Manufacturing: Machine safety guards, robotic cell emergency stops.

A Saudi Arabian oil refinery deployed HIMA F3430 modules in its crude distillation unit’s ESD system. The module’s SIL 3 certification and hot-swap capability reduced annual downtime by 72 hours, saving $1.2M in production losses. Its IP65-rated design also withstood desert dust and temperature swings (-10°C to +55°C), outperforming legacy relays that failed prematurely in harsh conditions.

Compared to similar SIL 3 relay modules:

- Superior Environmental Range: Operates up to +85°C, 25°C higher than most competitors, critical for sun-exposed outdoor cabinets.

- Faster Diagnostics: 99% fault coverage vs. industry average of 95%, minimizing undetected failures.

- Modular Flexibility: Native Modbus RTU support eliminates need for protocol converters, reducing integration costs by 20%.

- Longevity: 100,000-cycle relay life (resistive load), 50% longer than standard relays.

HIMA F3430

- Safety Requirements: Confirm SIL 3 is mandatory for your application (e.g., IEC 61511-mandated processes).

- Load Type: Ensure 500 mA capacity matches your actuators (e.g., solenoid valves, pilot relays).

- Environment: Use IP65-rated enclosures for outdoor/washed-down areas; derate current by 20% at temperatures >60°C.

- Scalability: Pair with HIMA’s HIMax I/O expansion modules for systems requiring >4 channels.

- Installation:

- Torque terminal screws to 1.2 N·m to prevent loose connections; route power cables separately from signals to avoid EMI.

- Use anti-static wrist straps to protect against ESD during handling.

- Configuration:

- Program via HIMA’s HIMax Workbench; validate safety logic with TÜV-approved tools.

- Maintenance:

- Replace modules every 10 years or 100,000 cycles (whichever comes first).

- Clean contacts annually with dry cloth to remove corrosion in humid environments.

- Safety Compliance:

- Follow IEC 61511 guidelines for SIS design; never use non-certified relays in parallel.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

HIMA F3430 and other industrial automation spare parts. Visit our website

www.xydcontrol.com or contact us for sales and technical support, ensuring reliable safety solutions for your critical operations.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide