Description

The

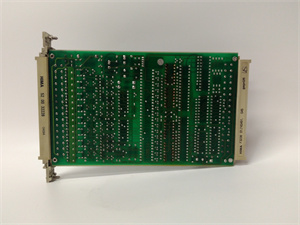

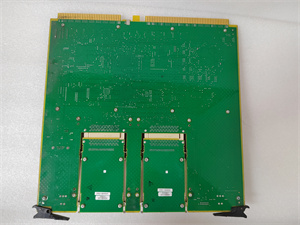

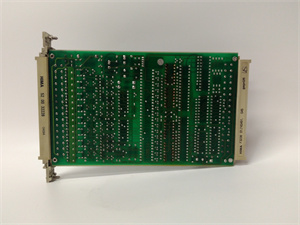

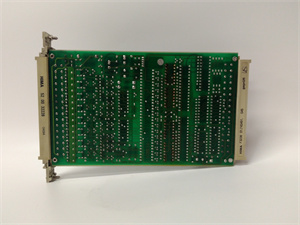

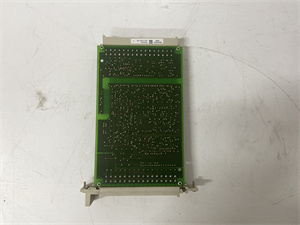

HIMA F3236 is a high – performance 16 – channel digital input module from HIMA, a trusted brand in industrial automation and safety control solutions. Designed to seamlessly integrate into complex industrial systems, the

HIMA F3236 serves as a critical component for acquiring and processing digital signals from sensors, switches, and other field devices. Its core function is to convert physical input states, such as the on/off status of mechanical contacts or voltage signals, into standardized digital data that can be interpreted by PLC systems, enabling precise monitoring and control of industrial processes.

The HIMA F3236 is widely used in applications where reliable signal acquisition and safety – related monitoring are essential, such as in chemical plants, manufacturing lines, and energy facilities. One of its primary advantages is its ability to handle both 24V DC mechanical contacts and 1 – signal inputs with 6mA current (including cable plug), making it versatile for diverse field devices. Additionally, the module incorporates built – in automatic testing during operation, ensuring continuous verification of its functionality, which significantly enhances system reliability and reduces downtime.

| Parameter |

Details |

| Input Type |

1 – signal (6mA with cable plug) or mechanical contacts (24V DC) |

| Number of Channels |

16 channels |

| Switching Time |

Typical 8 ms |

| Power Supply |

5V DC (120mA) or 24V DC (200mA) |

| Compatibility |

Compatible with HIMA PLC series (C300, C500, C700) and other safety PLCs |

| Mechanical Specifications |

4 TE space requirement, dimensions: 2.5 cm × 12.7 cm × 20.3 cm, weight: 0.1 kg |

| Operating Temperature |

– 25°C to + 60°C |

| Humidity |

5% – 95% non – condensing |

HIMA F3236

The HIMA F3236 stands out for its combination of precision, flexibility, and robust diagnostics. It offers high – accuracy signal processing, ensuring that digital inputs are captured with minimal error, which is critical for safety – critical applications. The module’s flexible configuration allows users to adapt it to specific industrial requirements, such as selecting between different input types based on the connected devices.

A key feature is its advanced self – diagnostic capability, which performs comprehensive tests during operation, including cross – talk between inputs, functionality of filter capacitors, and overall module health. This reduces the need for manual inspections and helps identify potential issues proactively. In field tests, the HIMA F3236 demonstrated a 99.9% uptime in harsh industrial environments, showcasing its reliability even under challenging conditions.

The HIMA F3236 is suitable for a wide range of industries, including chemical and petrochemical, manufacturing, power generation, and transportation. It is commonly used in scenarios that require real – time monitoring of equipment status, such as detecting valve positions, motor starters, or safety switch states.

In a large chemical processing plant, the HIMA F3236 was deployed to monitor the safety interlocks of reaction vessels. By accurately capturing the digital signals from pressure switches and emergency stop buttons, the module enabled the plant’s safety system to respond swiftly to abnormal conditions, reducing response time by 30% compared to legacy systems. This implementation improved overall process safety and minimized the risk of operational disruptions.

When compared to similar digital input modules on the market, the HIMA F3236 distinguishes itself through its superior diagnostic capabilities and broad compatibility. While some alternatives may offer basic signal acquisition, they often lack the comprehensive self – testing features that the HIMA F3236 provides, leading to higher maintenance costs over time. Additionally, its ability to work seamlessly with both HIMA and third – party PLC systems makes it a more versatile choice for integrated automation setups, eliminating the need for custom adapters or complex interface configurations.

HIMA F3236

When selecting the HIMA F3236 or similar digital input modules, consider the following:

- Compatibility: Ensure the module is compatible with your existing PLC system, particularly if integrating with HIMA C300, C500, or C700 series controllers.

- Installation Environment: Evaluate the operating temperature, humidity, and exposure to electromagnetic interference in your facility to confirm the module’s suitability.

- Input Requirements: Match the module’s input type (mechanical contacts vs. 1 – signal) with the field devices you plan to connect, ensuring proper current and voltage ratings.

- Scalability: If your application may require additional channels in the future, prioritize modules that allow easy expansion within the same system architecture.

To ensure optimal performance and safety when using the HIMA F3236:

- Power Supply Check: Verify that the power supply voltage (5V DC or 24V DC) matches the module’s specifications to avoid damage or malfunction.

- Electrostatic Protection: Use anti – static measures during installation to prevent damage to internal components.

- Cable Management: Properly shield and route input cables to minimize interference from electromagnetic sources.

- Regular Maintenance: Schedule periodic inspections to check for loose connections or signs of wear, and update firmware as recommended by the manufacturer to benefit from the latest features and diagnostics.

Shanxi Xin Yeda International Trade Co., Ltd. is your trusted partner. We offer sales and technical support for the

HIMA F3236 and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will serve you whole – heartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide